A ceramic ferrule pc spherical surface processing machine

A spherical surface processing and ceramic ferrule technology, which is applied to spherical surface grinders, metal processing equipment, and machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of small cylindrical surface precision and low work efficiency of optical fiber ceramic ferrules, and achieve processing The method is feasible, the structure design is reasonable, and the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

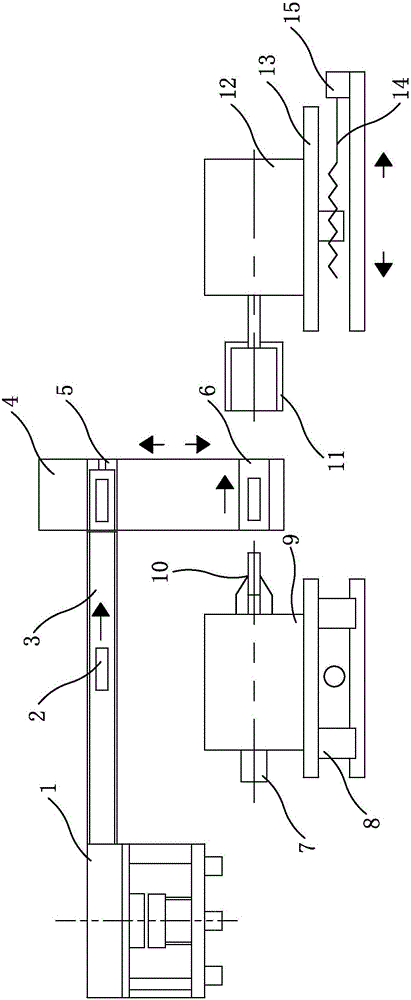

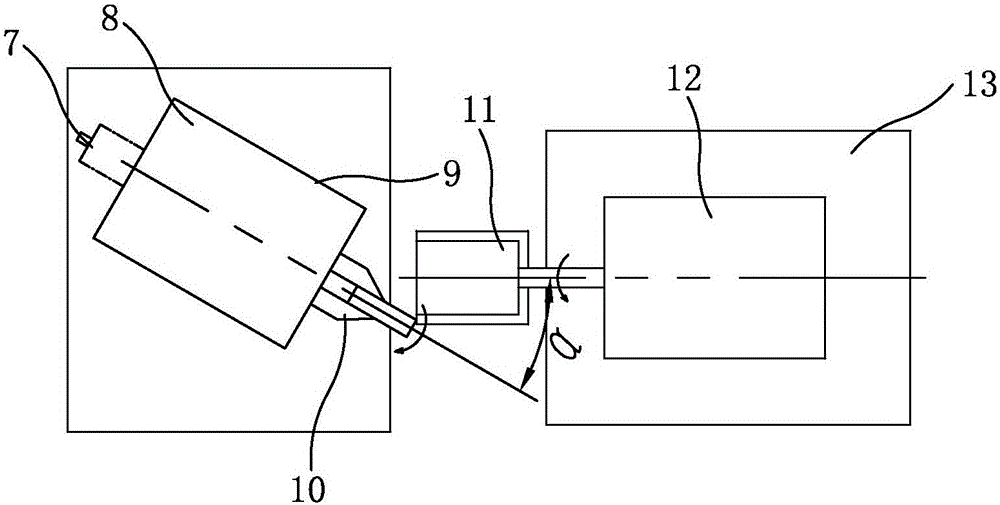

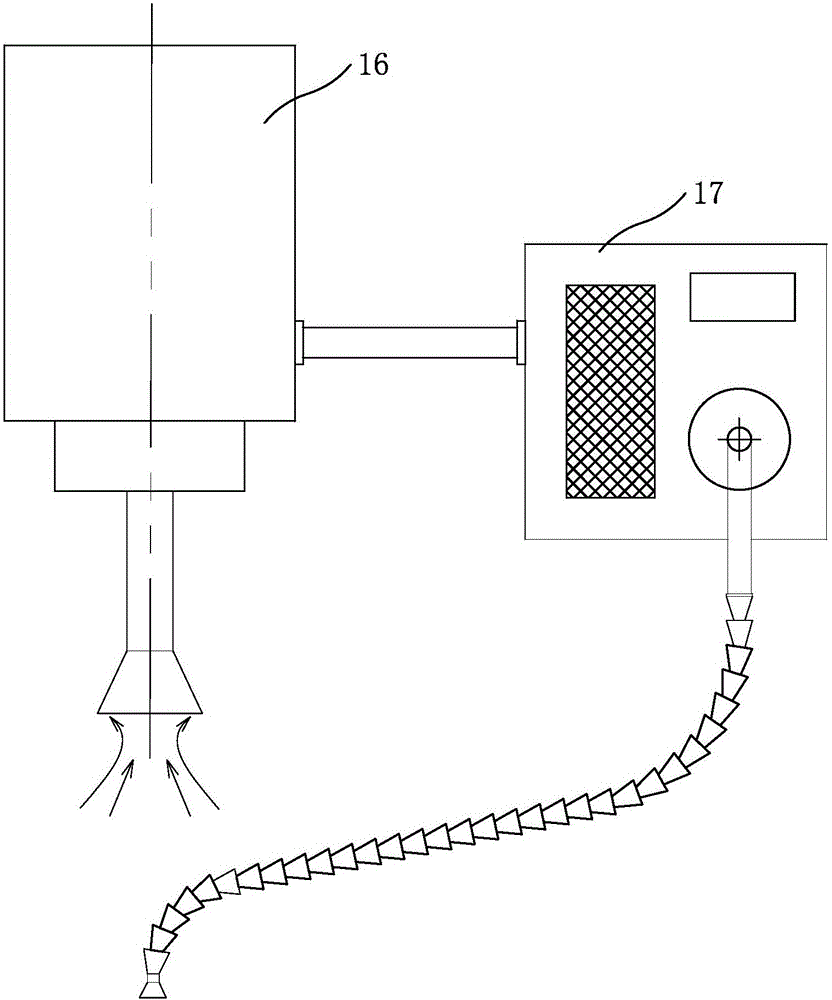

[0013] In conjunction with the accompanying drawings, the structure and processing principles of the present invention will be further described. like Figure 1 ~ Figure 3 As shown, the processing machine includes vibrating hopper and discrimination system 1, automatic loading and unloading system, precision feeding system, exhaust and oil mist filtration system 16, cooling and lubrication system 17, workpiece clamping spindle system and grinding spindle system , the vibrating hopper and the discrimination system are connected to the automatic loading and unloading system, the processing position of the automatic loading and unloading system is provided with a workpiece clamping spindle system and a grinding spindle system, that is, the workpiece 2 outlet of the automatic loading and unloading system is located in the workpiece clamping spindle system Between the grinding spindle system, the automatic loading and unloading system drives the workpiece to the workpiece clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com