Oil mist separation device used for mechanical and electrical equipment and separation method

A technology for oil mist separation and electromechanical equipment, applied in separation methods, combined devices, dispersed particle separation, etc., can solve problems such as damage to the physical and mental health of workers, waste of resources, and no oil mist separation system purification device, and achieve filtration efficiency. Efficient and durable, improving machining precision, and the effect of insignificant changes in efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

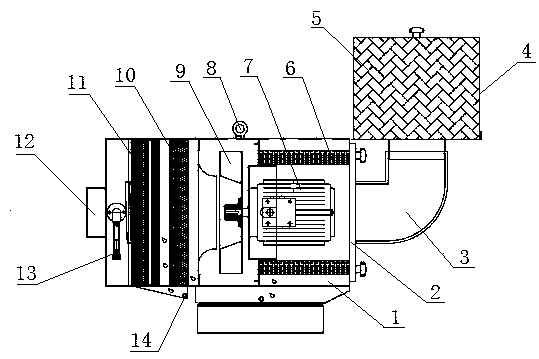

[0024] An oil mist separation device for electromechanical equipment, which consists of: a base 1, the base has a groove, the middle part of the groove is installed with a motor 7, and the sides of the motor are respectively installed with two three Stage filtering device 6, the front end of the motor is connected to the centrifugal impeller 9 through a connecting shaft, the front end of the centrifugal impeller is equipped with a secondary filtering device 10, the front end of the secondary filtering device is equipped with a primary filtering device 11, the An oil mist suction port 12 is installed on the front end of the base.

Embodiment 2

[0026] According to the oil mist separation device for electromechanical equipment described in Embodiment 1, the front end surface of the three-stage filter device is attached to the side surface of the inner groove of the base, and the rear end surface of the three-stage filter device is in contact with the inner surface of the end cover 2. The end faces are bonded, and the end cover is connected with the bottom plate through bolts.

Embodiment 3

[0028] According to the oil mist separation device for electromechanical equipment described in Embodiment 2, the end cover has a hole, and a connecting elbow 3 is installed in the hole, and the connecting elbow is connected to the high-efficiency filter 5 through the connecting joint. Connection, the side of the high-efficiency filter has a clean air outlet 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com