Rotary dynamic milling torque measurement instrument

A rotary dynamic and torque measurement technology, used in measurement/indication equipment, metal processing mechanical parts, metal processing equipment, etc., can solve the problems of measurement results error, complex tool holder structure, size limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

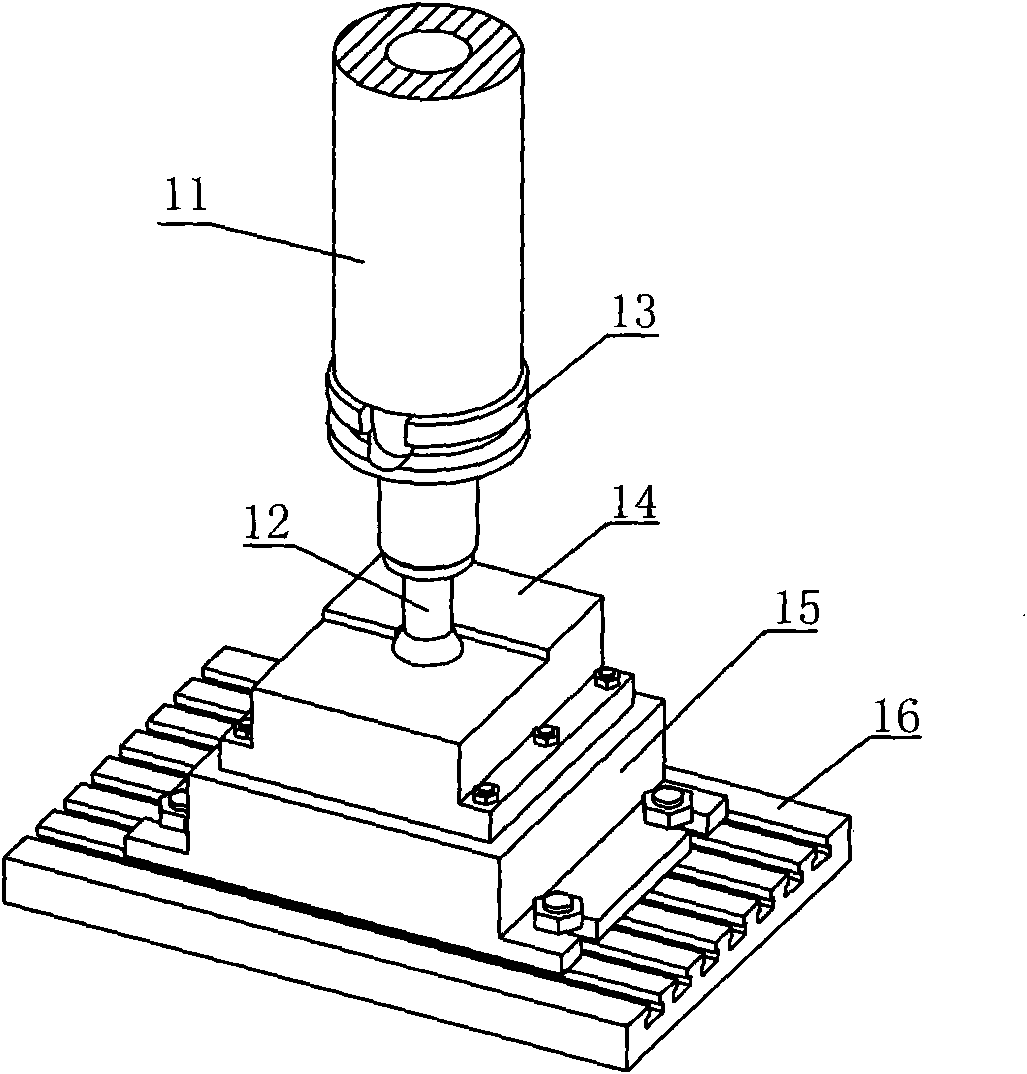

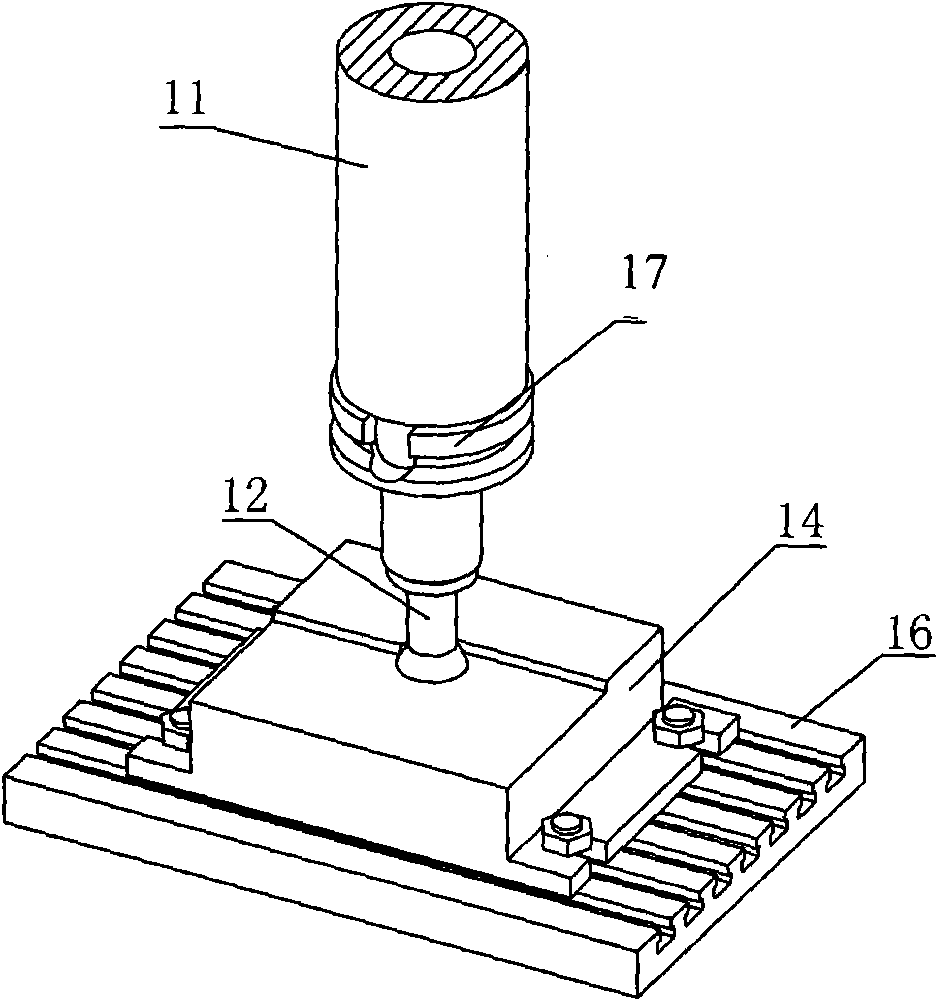

[0043] The present invention will be further described below in conjunction with the examples shown in the accompanying drawings. The rotary dynamic milling torque measuring instrument of the present invention comprises:

[0044] 1. Integrated torque sensor holder

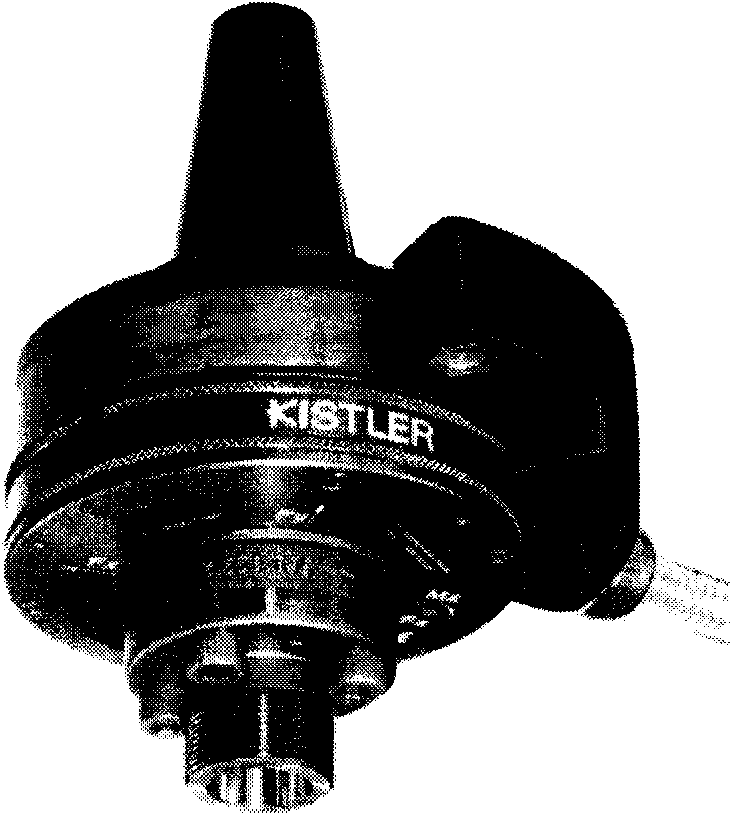

[0045] This is the body of the rotary dynamometer, which is used to connect the rotary cutting dynamometer to the machine tool spindle (via the taper) and to mount the tool. See Figure 4 , the conical shank of the integrated torque sensor shank complies with the BT50 national standard (GB / T 10944.1-2006), the elastic sensitive element 41 is directly processed on the shank, and then the resistance strain gauge 40 is pasted on the sensitive element to form an electric bridge. It is composed of two 45° dual resistance strain gauges, so that the torque sensor is directly integrated into the tool handle. The protective cover 42 is used to protect the strain gauge, and the screw 43 fixes the protective cover 42 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com