High-speed full-automatic irretention trouser and training trouser production line and method for producing same

A technology for incontinence trousers and training trousers, applied in transmission devices, medical science, bandages, etc., can solve the problem of inability to realize thick-layer or multi-layer welded sheet welding, inability to perform secondary welding, tertiary welding, and affect the production of production equipment Efficiency and other issues, to achieve the effect of easy mastering and maintenance, novel structure design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

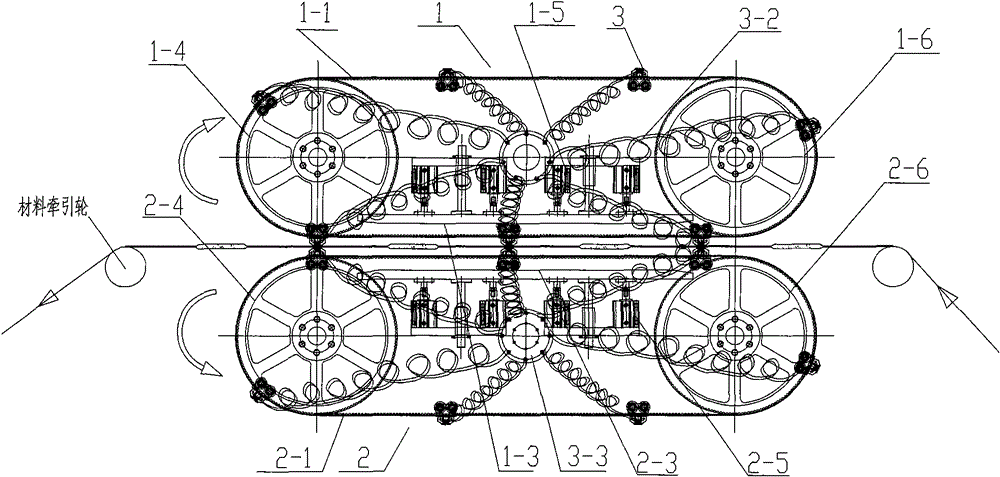

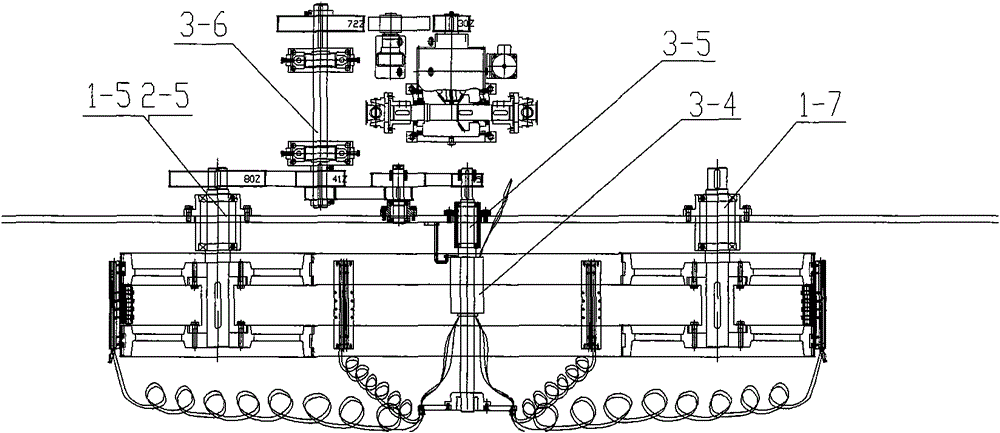

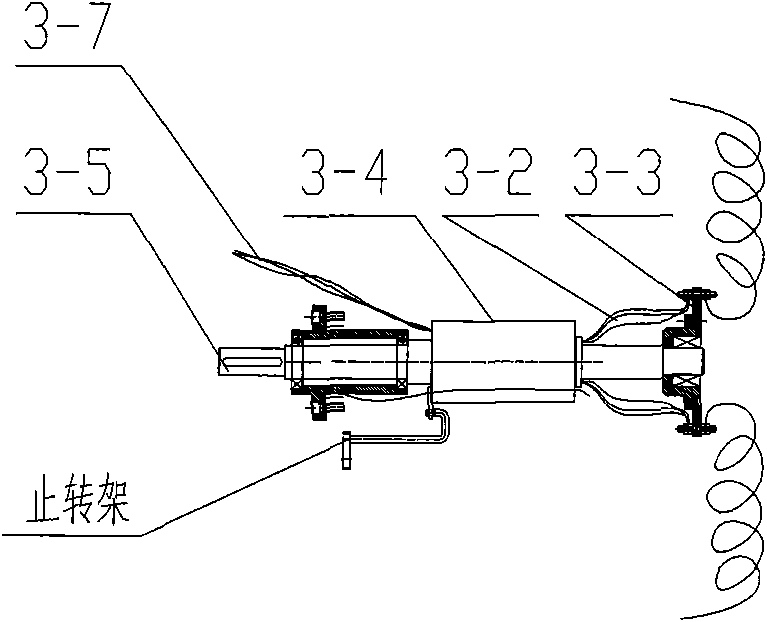

[0015] Embodiment 1: with reference to attached Figure 1~3 . High-speed automatic incontinence trousers and training trousers production line, which includes incontinence trousers and training trousers production line, the upper synchronous transmission mechanism 1 and the lower synchronous transmission mechanism 2 in the trouser waist heat-press welding equipment in the incontinence trousers and training trousers production line pass through respectively The shaft is located on the side of the vertical frame 4 and the upper synchronous transmission surface 1-1 of the upper synchronous transmission mechanism 1 is opposite to the synchronous transmission surface 2-1 of the lower synchronous transmission mechanism 2, and the distances between a plurality of tooth-shaped pressing blocks 3 are opposite to each other. Located on the upper synchronous transmission surface 1-1 and the lower synchronous transmission surface 2-1, the upper synchronous transmission surface 1-1 and the ...

Embodiment 2

[0021] Embodiment 2: on the basis of embodiment 1, the method for incontinence pants, training pants production line of high-speed automatic incontinence pants, training pants, it comprises incontinence pants, training pants production line, control screen instruction in incontinence pants, training pants production line Transport the waist circumference of PE or PP incontinence pants and training pants that need to be welded to the tooth-shaped pressing block between the upper synchronous transmission surface 1-1 and the lower synchronous transmission surface 2-1 of the upper synchronous transmission mechanism 1 and the lower synchronous transmission mechanism 2 3 rooms, the back of the tooth-shaped pressing block 3 is equipped with a roller 3-8 and is in a pressure rolling fit with the plane guide rail 1-3 or 2-3, and the upper and lower cylinders 1-5 and 2-5 are synchronously driven by the upper and lower plane guide rails respectively. When the tooth-shaped pressing block 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com