Sealing dustproof method and sealing dustproof device of bell-less furnace top gas seal box

A technology of dust-proof device and airtight box, which is applied in the arrangement of bells and funnels, can solve problems such as inability to seal, and achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

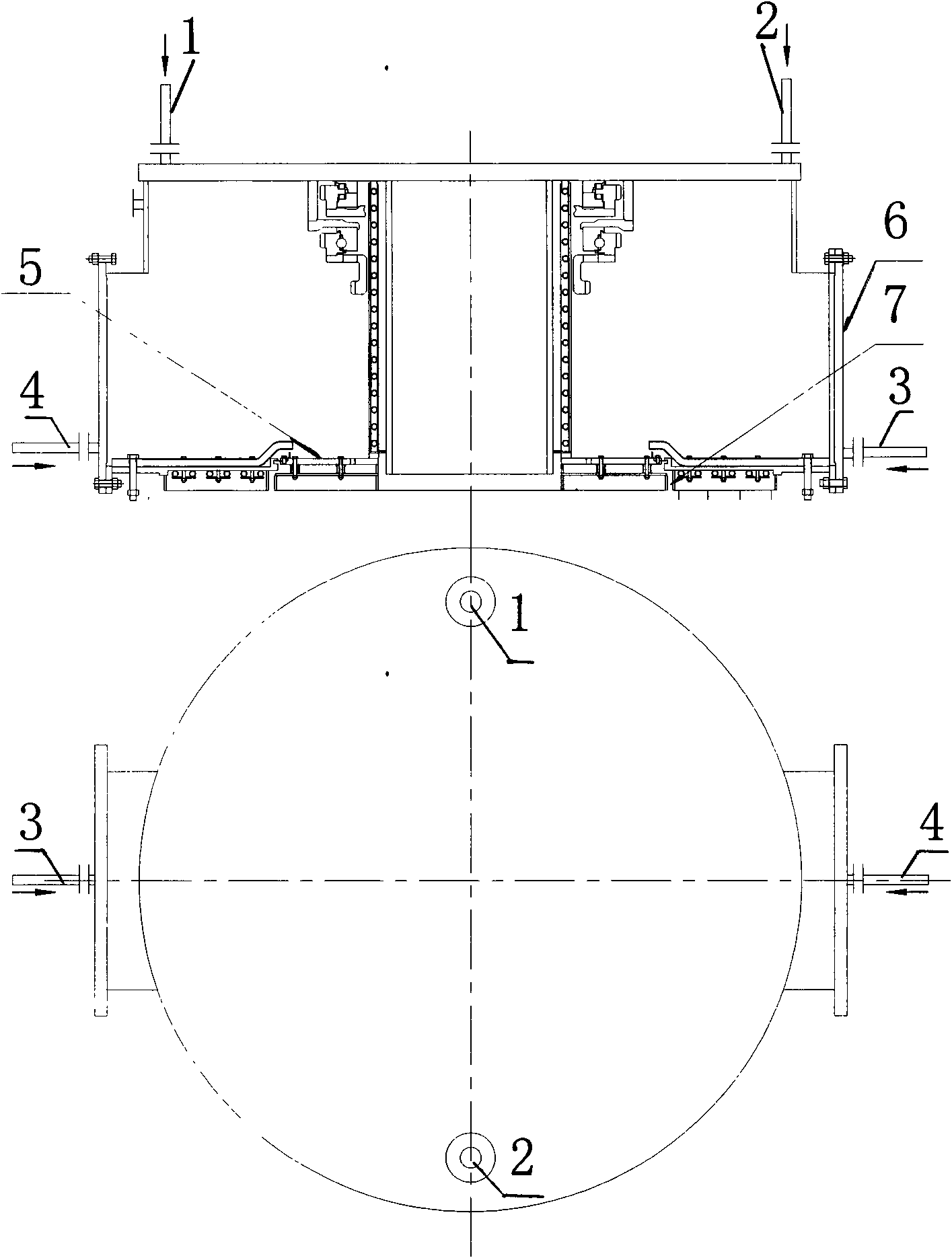

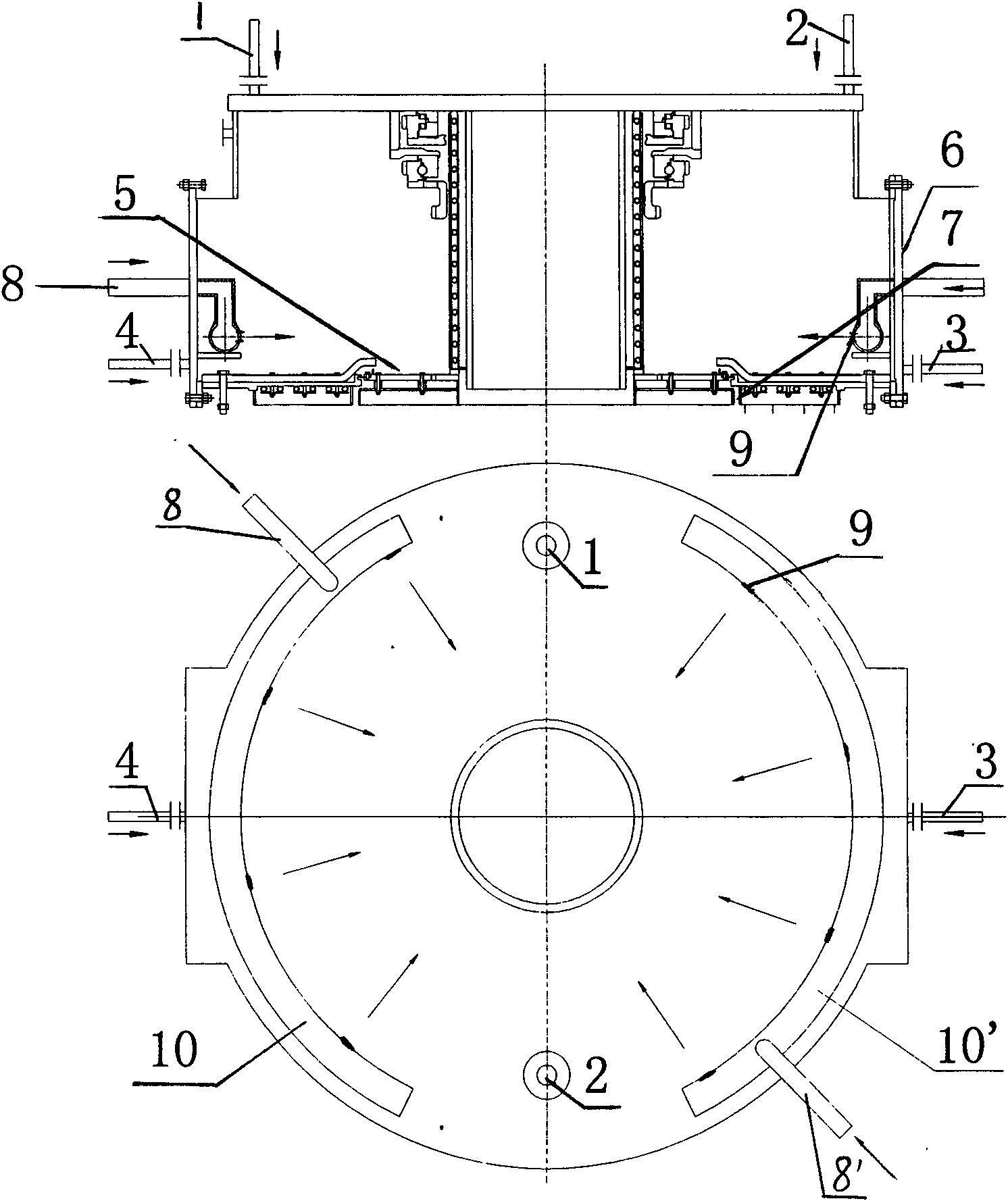

[0020] Embodiment 1: refer to figure 2 .

[0021] A method for sealing and dust-proofing an airtight box at the top of a bell furnace, on the basis of four nitrogen purge points in the prior art, the following content is added: two semi-annular pipes 10, 10', a row of small purge holes 9 are evenly opened inside the semi-annular pipe, and nitrogen gas is passed into the two semi-annular pipes so that the nitrogen passes through the small purge holes 9 on the inside of the semi-annular pipe toward the rotating chassis 5 and the airtight box The annular seam between 7 directions (such as figure 2 arrow), when the nitrogen pressure is higher than the pressure in the furnace, an air curtain is formed in the circular seam between the transmission mechanism and the stationary box 7 circles, and the air curtain is opposite to the chassis when the rotating chassis 5 rotates. Perform purging while blocking external dust from rushing into the box.

Embodiment 2

[0023] The sealing and dustproof device and installation structure of the airtight box are as follows: figure 2 As shown, at the annular seam 7 between the rotating chassis 5 and the box body, two semi-annular pipes 10, 10' are installed and fixed inside the box body, and the two nitrogen gas inlet pipes 8, 8' are connected to the two semi-annular pipes respectively. 10, 10', 16 small purge holes 9 are evenly opened inside the semi-circular pipe, and the small holes 9 form a nitrogen curtain, which plays the role of active sealing and effectively prevents the deposition of dust in the furnace.

[0024] The semi-annular pipe is made of a steel pipe with a diameter of 40 mm to make a circle according to the inner diameter of the box, and then divided into two semi-annular pipes for installation. figure 2 As shown by the arrow in the top view), there are 16 small holes 9 of 10mm in total. These small holes 9 form an air curtain around the 7th ring seam, which not only prevents ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com