Wind power generation unit blade reinforced with needle fiber and fabrication process thereof

A fiber-reinforced, wind turbine technology, applied in the field of blades, can solve the problems of increasing blade weight, high raw material cost, increasing blade cost, etc., and achieve the effects of increasing resin inflow speed, improving layer shear strength, and improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

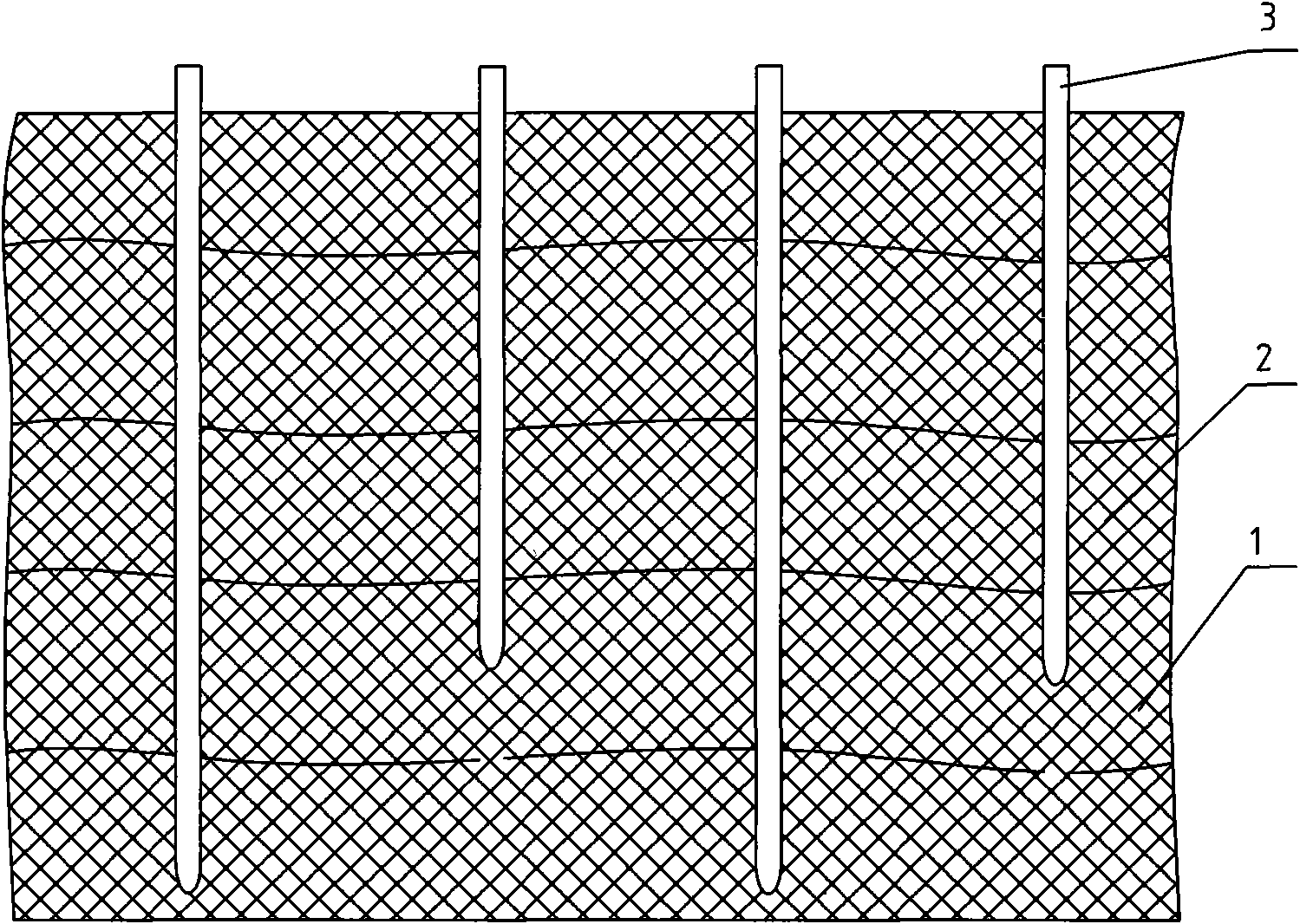

[0016] Embodiment 1: as figure 1 As shown, a needle-punched fiber-reinforced wind turbine blade includes a laminated fiber cloth layer 1, a matrix resin material 2 and fibers 3, and the fibers 3 are vertically densely distributed on the laminated fiber cloth layer 1, and the laminated fiber cloth layer A matrix resin material 2 is impregnated between the plies 1 . The matrix resin material 2 is selected from epoxy resin or polyester resin. The fiber cloth layer 1 is a glass fiber cloth layer.

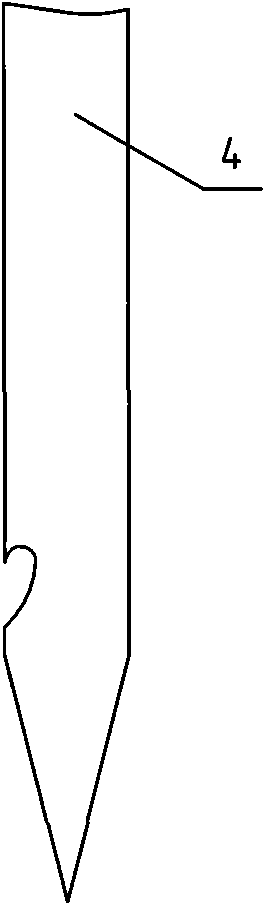

[0017] The manufacturing process of the needle-punched fiber-reinforced wind turbine blade includes the following steps in sequence: (1) Mold preparation: cleaning the mold, removing impurities on the surface of the mold; (2) Fiber cloth laying: laying the glass fiber cloth according to the design It is required to be laid in the cleaned mold to form a laminated glass fiber cloth layer 1; (3) fiber needle punching: use a barbed needle 4 (such as figure 2 As shown) the glass fiber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com