Fluidized selective deslagging device

A selective and fluidized technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problem of incinerators not being able to fluidize and operate normally, and achieve the effect of prolonging life and reducing scouring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

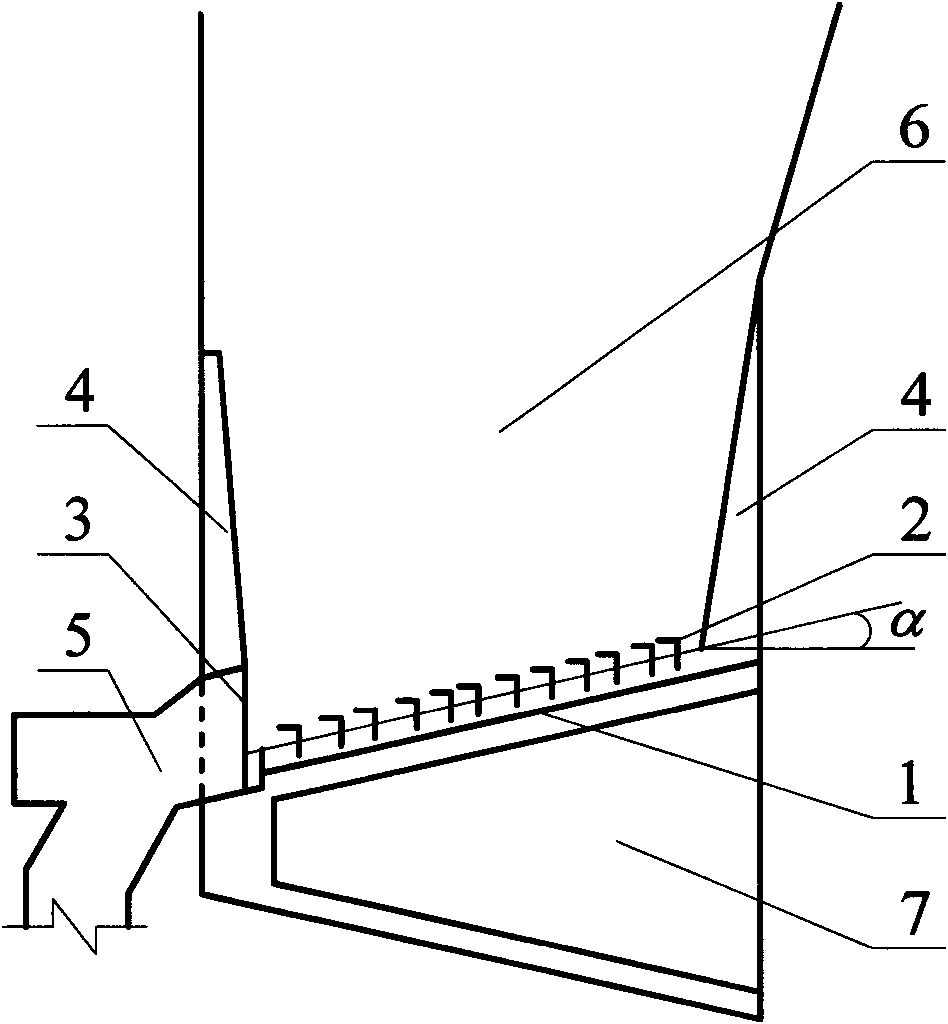

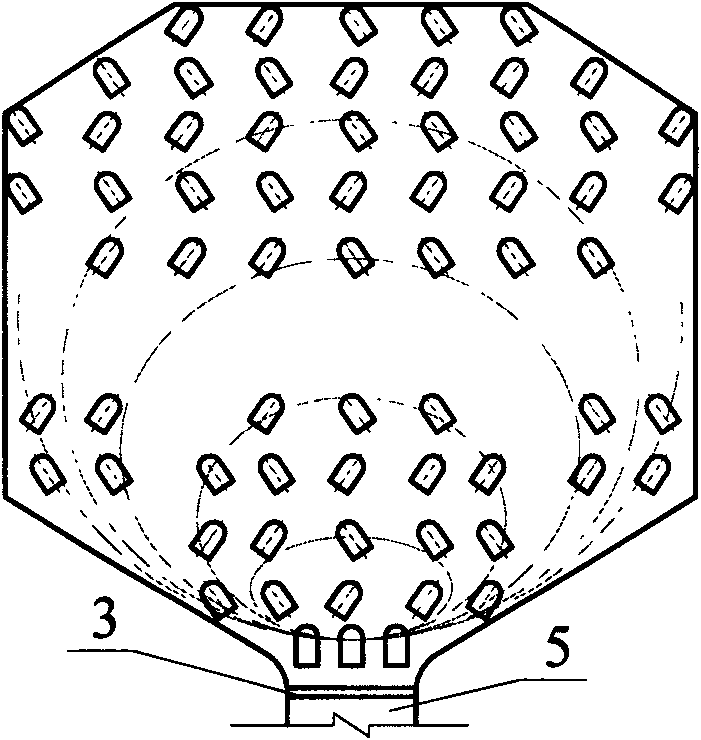

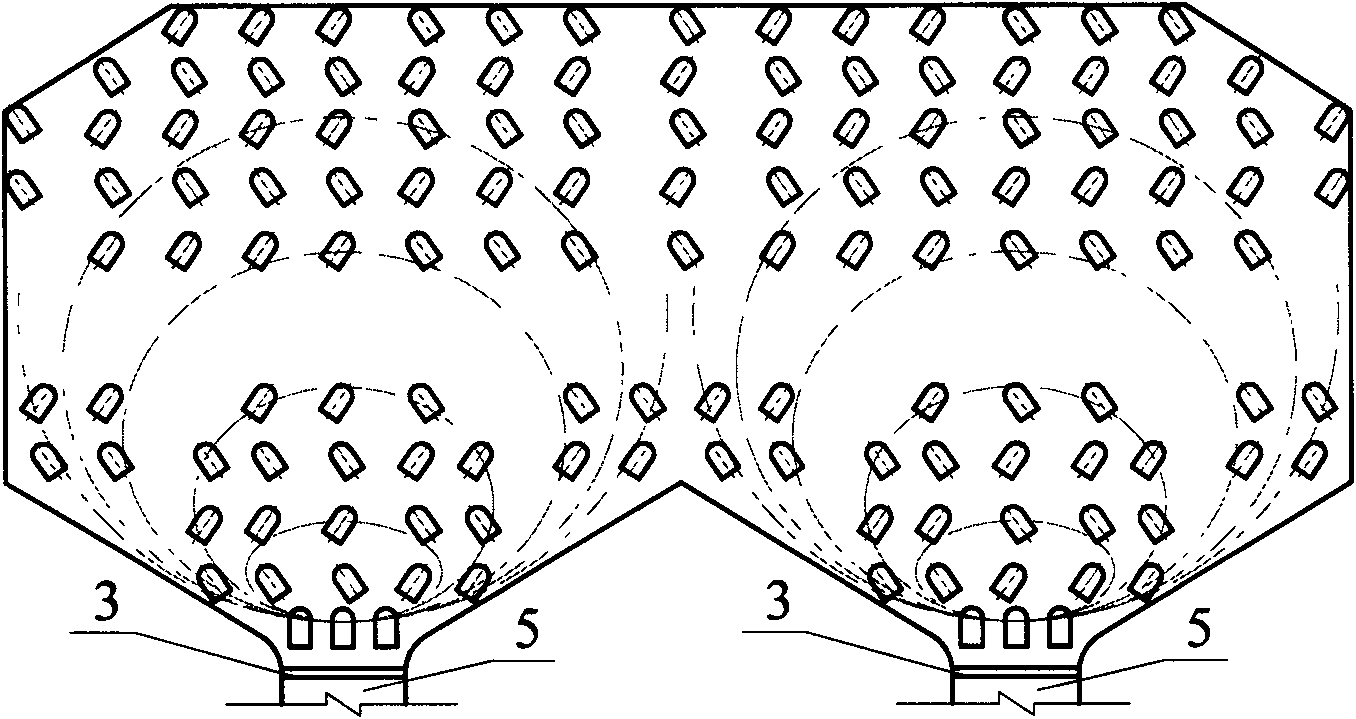

[0017] Such as figure 1 As shown, the present invention includes an air distribution plate 1, an air cap 2, a slag discharge channel on the bed and a furnace enclosure structure 4, which are arranged at the bottom of the incinerator furnace. The air distribution plate 1 is arranged at the bottom of the furnace, surrounded by a furnace enclosure structure 4, and the furnace enclosure structure is made of fire-resistant and wear-resistant materials. The slag discharge channel on the bed is composed of the slag discharge port 3 on the bed and the stepped channel 5. The slag discharge port on the bed is an opening formed by the stepped channel on the section of the furnace enclosure structure. The lower end is the stepped platform of the stepped channel 5, and the height H of the slag discharge port is greater than the width of the largest slag block in the bottom slag. During the waste incineration process, bottom slag, which is far more complex and wider than coal-fired, will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com