Online device for rapidly detecting quality indicators of prepreg tape

A technology of quality index and prepreg tape, which is applied in measurement devices, color/spectral property measurement, material analysis by optical means, etc., can solve the problems of reagent consumption, laborious, time-consuming analysis results, etc., and achieves time-saving detection and operation. Easy, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

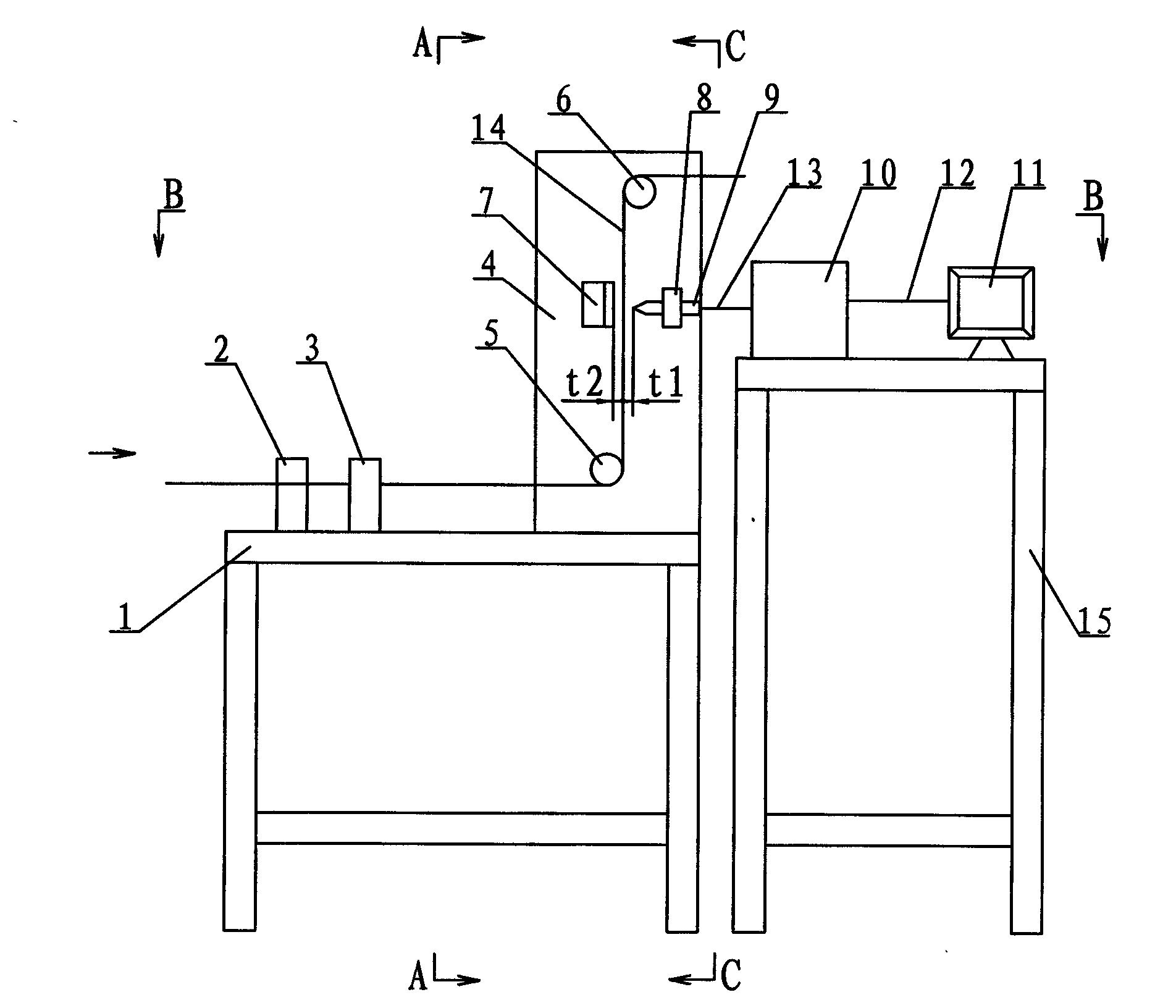

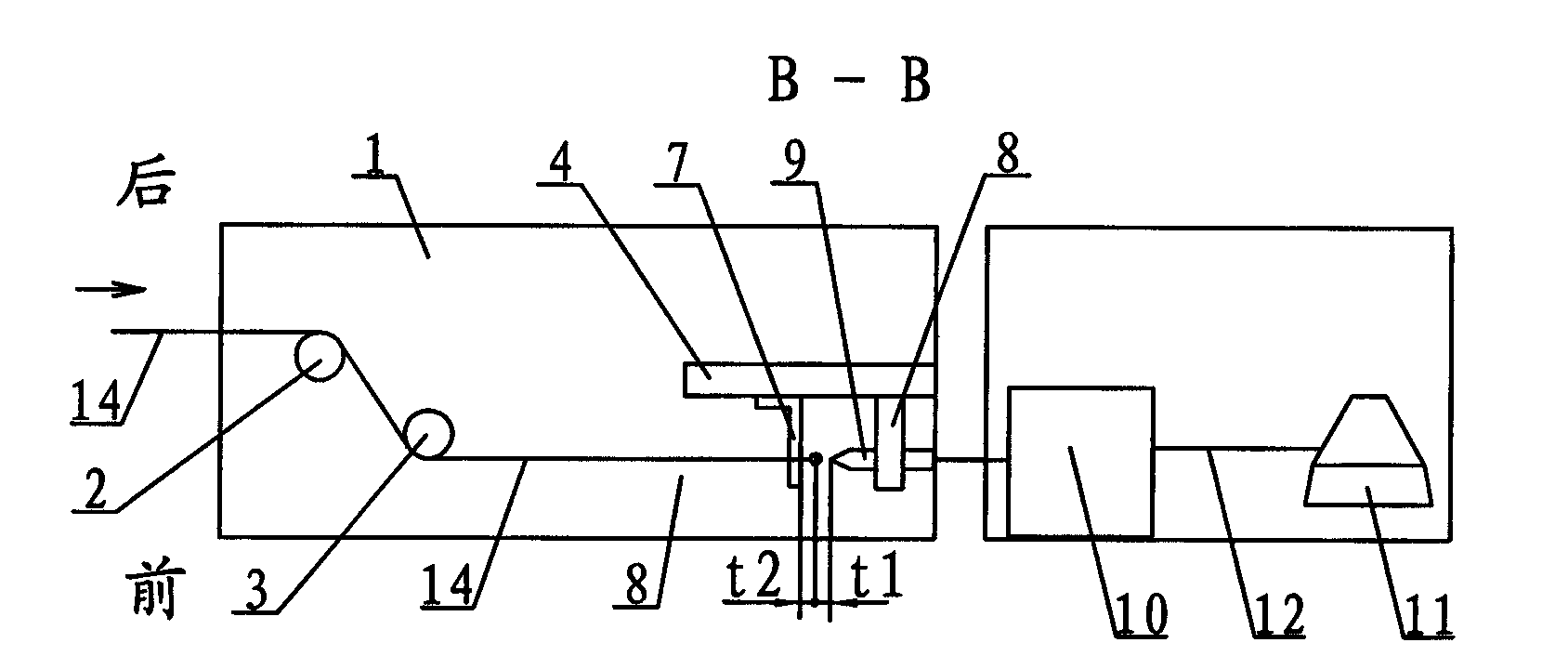

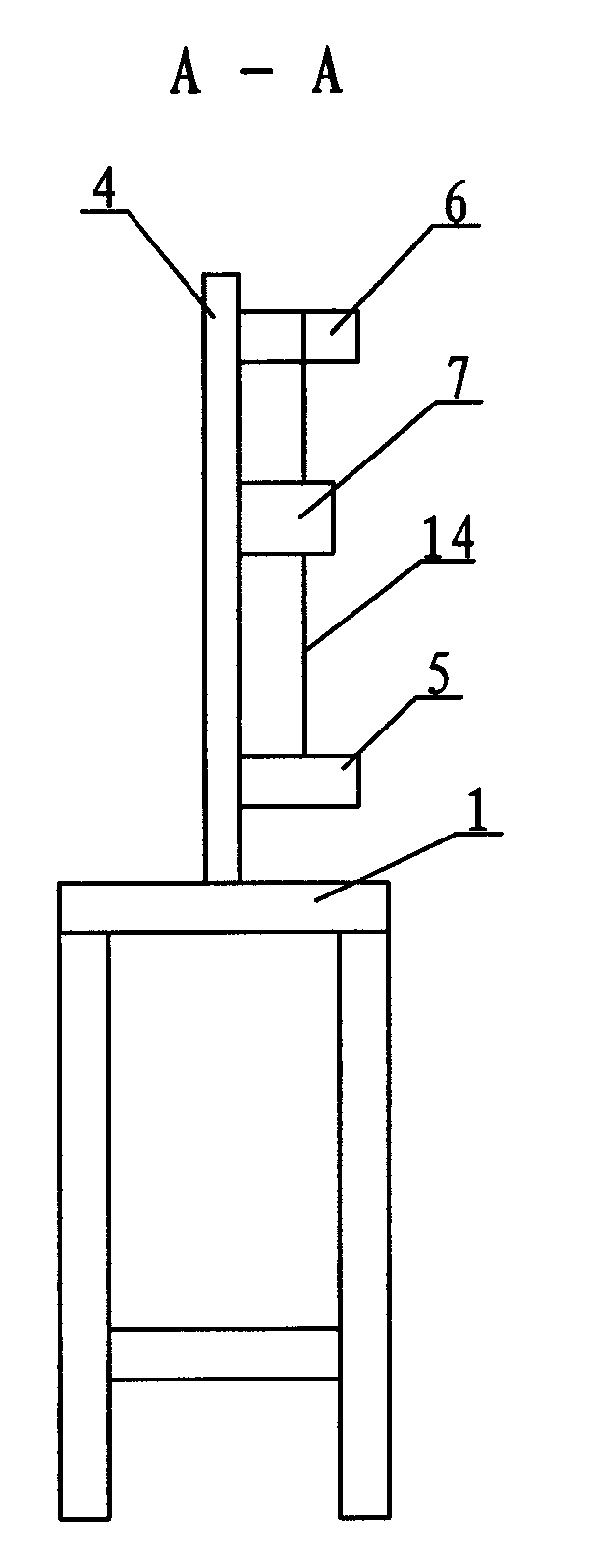

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment includes a first bracket 1, a first guide roller 2, a second guide roller 3, a support plate 4, a third guide roller 5, a fourth guide roller 6, a reflection plate 7, and a probe support frame 8 , probe 9, near-infrared spectrometer 10, computer 11, data transmission line 12, optical fiber 13 and the second support 15, near-infrared spectrometer 10 and computer 11 are respectively arranged on the upper end face of the second support 15, near-infrared spectrometer 10 and computer 11 Connected by the data transmission line 12, the first bracket 1 and the second bracket 15 are arranged longitudinally sequentially, the first guide roller 2 and the second guide roller 3 are vertically fixed on the upper end surface of the first bracket 1 respectively, and the third guide roller 5 is opposite to each other. The second guide roller 3 is vertically arranged, and one end of t...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 with figure 2 The present embodiment will be described. The probe 9 of the present embodiment has a diameter of 6 mm. Since the width of the prepreg tape 14 to be tested is only a few millimeters, this design enables the probe 9 to collect the information of the prepreg tape 14 to be tested. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, the distance t1 between the head of the probe 9 and the prepreg tape 14 to be tested is 1 mm, and the distance t2 from the end surface of the reflector 7 opposite to the probe 9 to the prepreg tape 14 to be tested is 1 mm. This design ensures that the collection of information is collected in a non-contact state, and the prepreg tape 14 to be tested is not damaged. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com