System for producing various vector beams

A light beam and vector technology, applied in the field of optical systems, can solve the problems of impact effect and promotion, low conversion efficiency, high system cost, etc., and achieve the effect of easy realization and promotion, strong practicability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

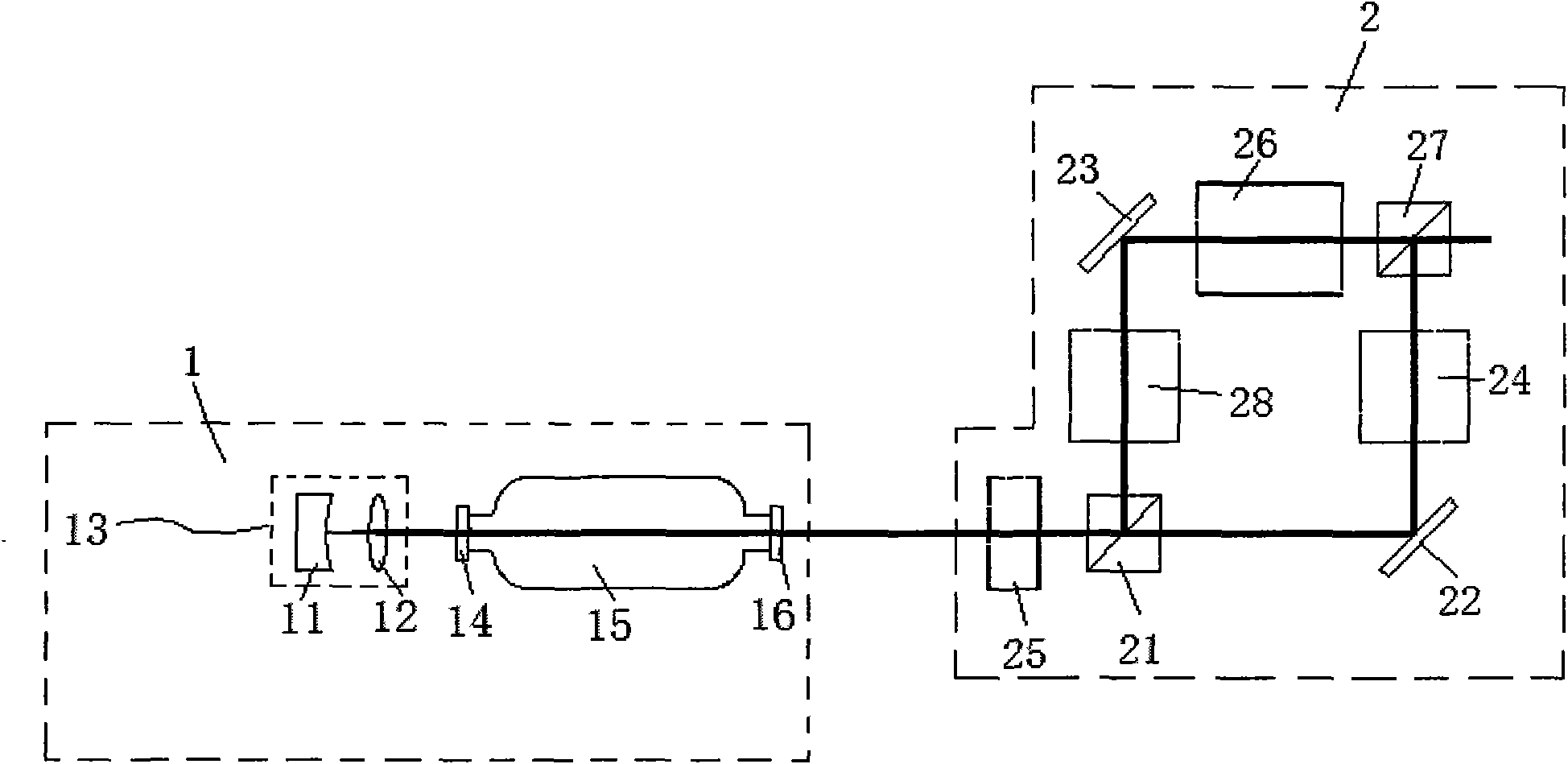

[0023] Such as figure 1 As shown, the present invention includes a cat's eye cavity laser 1 and a laser interference section 2 . The cat-eye cavity laser 1 is used to adjustably output a variety of different transverse modes, such as: TEM 00 、TEM 01 、TEM 10 、TEM 11 、TEM 02 and other modes. The laser interference part 2 can split and interfere the transverse mode output by the cat's-eye cavity laser 1, and generate various vector beams.

[0024] In the embodiment of the present invention, the cat's-eye cavity laser 1 is based on a He-Ne laser, and may also be based on other gas lasers, solid-state lasers, semiconductor lasers, dye lasers, and the like. The cat's-eye cavity laser 1 includes a cat's-eye inverter 13 , an antireflection window 14 , a He-Ne laser tube 15 and a cavity mirror 16 . The cat's eye inverter 13 is a cavity mirror of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com