Lug processing method

A processing method and tab technology, used in metal processing equipment, electrode manufacturing, manufacturing tools, etc., can solve problems such as poor welding, false welding, and leakage of protective tapes, simplify the processing process, improve the quality of the winding core, and provide The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

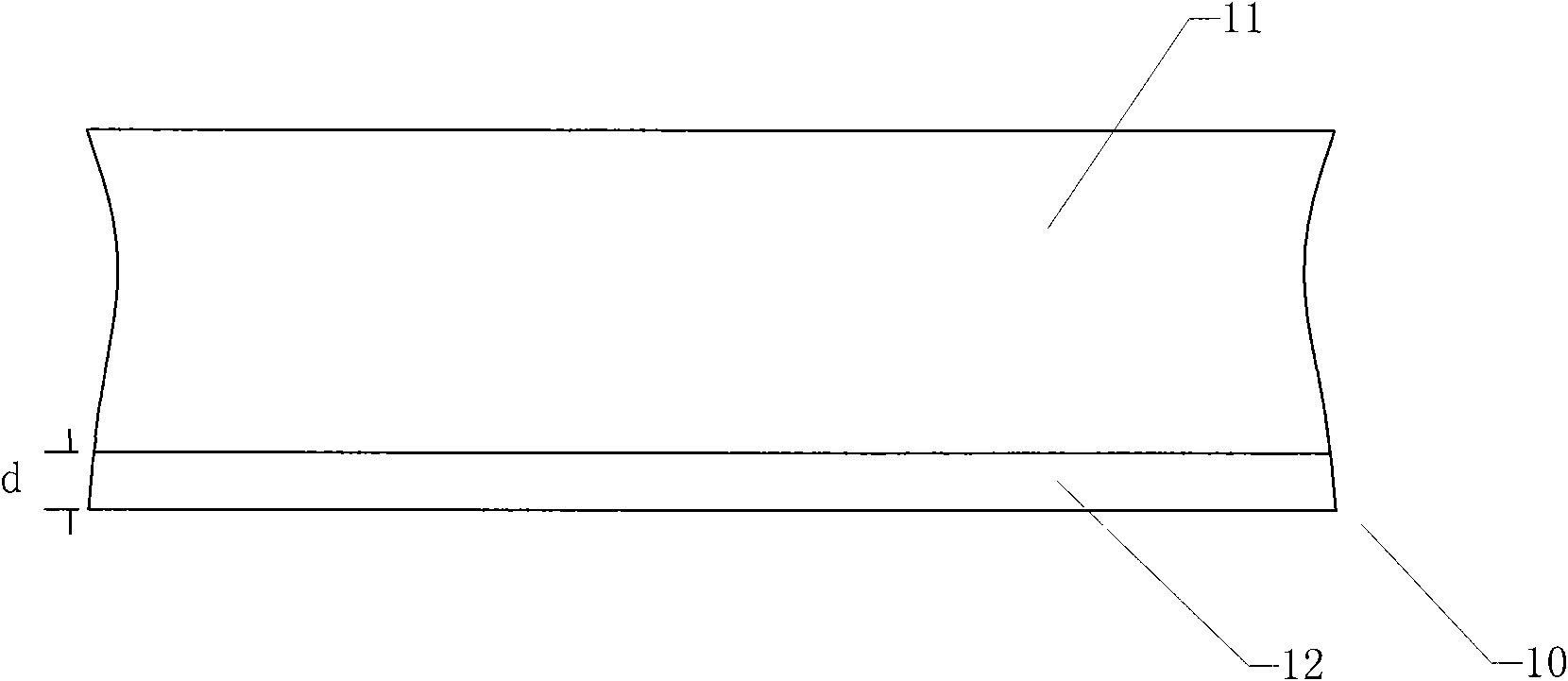

[0016] Figure 3-Figure 5 The pole piece obtained by adopting the tab processing method of the present invention is shown.

[0017] In this embodiment, the active material 11 is coated on the current collector 10 first, and then the tab processing is performed.

[0018] The specific process of tab processing is as follows:

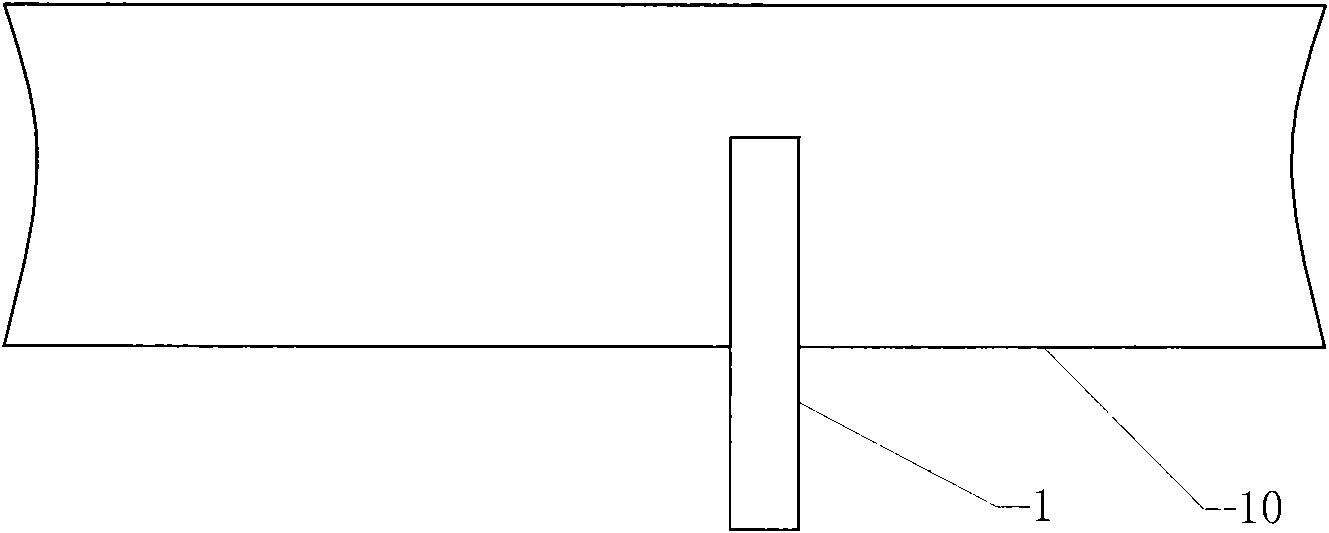

[0019] a. If image 3 As shown, a processing belt 12 of a certain width is defined on the lower edge of the current collector 10, the width of the processing belt 12 is d, and the upper area of the processing belt 12 is coated with an active material 11;

[0020] b. According to the required position, size and shape, cut the processing band 12 of the current collector 10 with a laser to obtain the tab 13 integrated with the current collector 10, see Figure 4 and Figure 5 .

[0021] Such as image 3 As shown, the current collector 10 is a whole, and the current collector 10 is divided into two areas: the strip-shaped area near the edge is the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com