Spark plug hole precast process for casting engine aluminum alloy cylinder cover by gravity

A spark plug hole and gravity casting technology, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., to achieve the effect of easy promotion, simple process, and improved wall thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

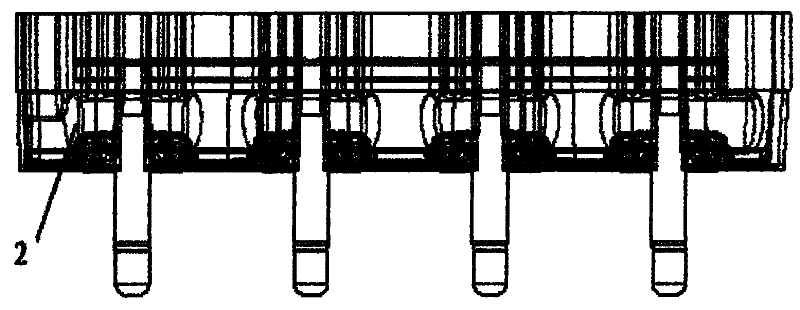

[0019] Put the cylinder head water jacket sand core and air passage sand core into the metal mold in the normal order, and then position the riser sand core and the low pressure oil passage sand core through the concave and convex positioning points and then position them on the gantry frame of the front and rear end molds . Then lower the sand core of the spark plug hole into the metal mold, close the mold and pour, solidify and take out. According to the structural characteristics of the product, the riser core and the spark plug hole sand core can also be made into an integral sand core, and the riser core can be positioned and lowered into the metal mold.

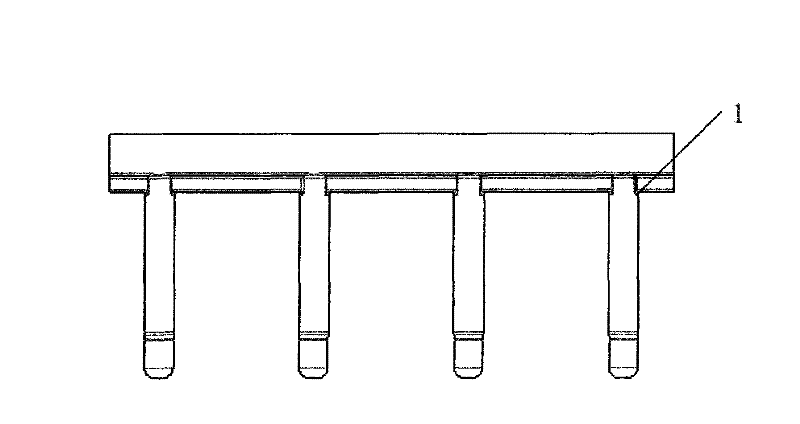

[0020] like figure 1 As shown, the spark plug hole sand core adopts the overall structure of the coated sand shell core or cold box technology, and the spark plug hole sand core is positioned through the core head part 1 .

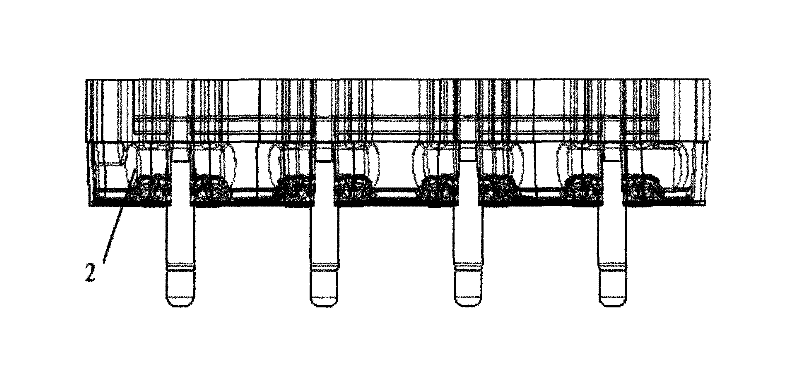

[0021] like figure 2 As shown, the riser core 2 has a mating surface for the positioning of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com