Small-size four-wheel drive stepless speed change loader

A four-wheel drive, continuously variable speed technology, applied in mechanically driven excavators/dredgers, control devices, transportation and packaging, etc. problems, to achieve the effect of making full use of engine power, improving the reliability of the whole machine, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

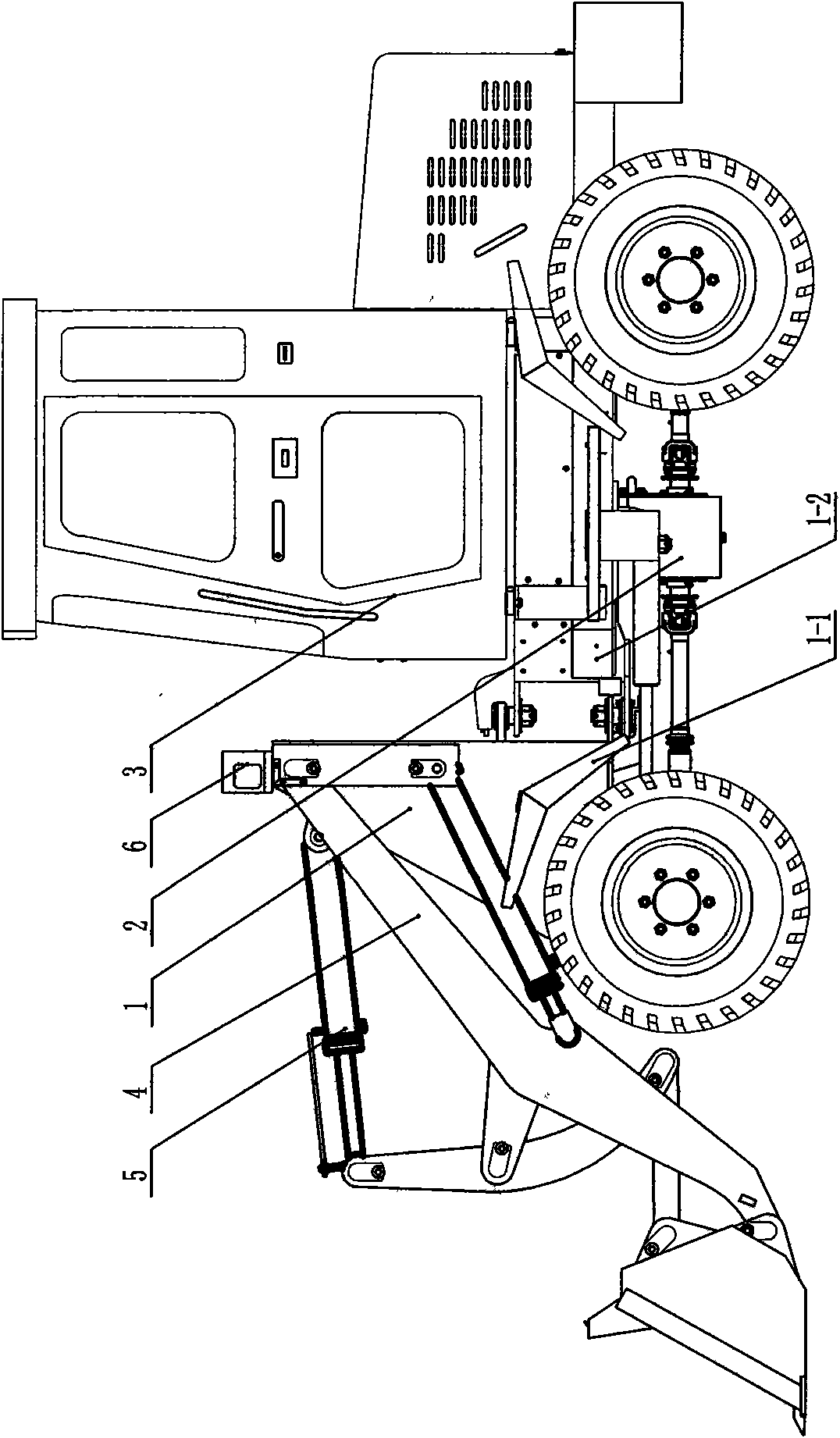

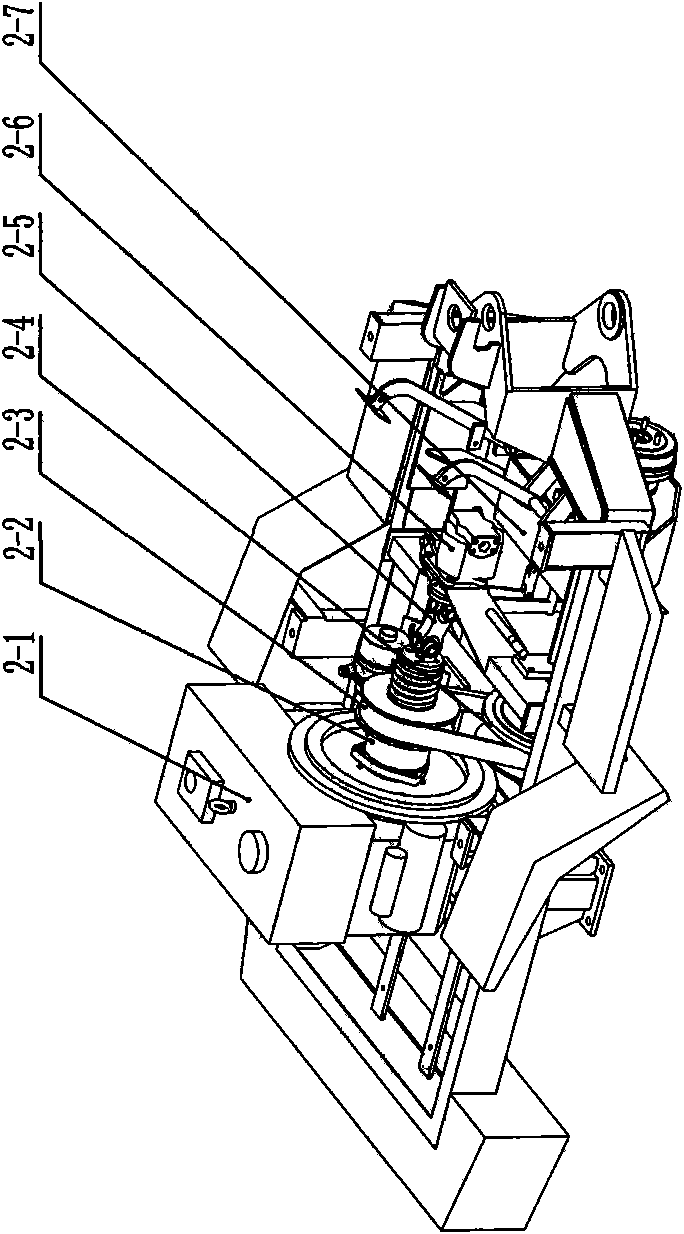

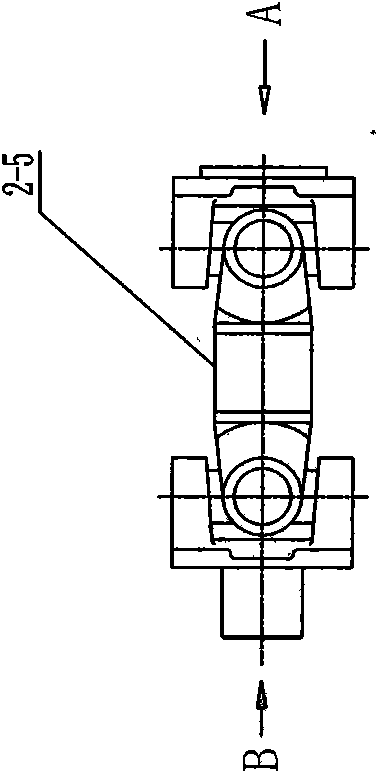

[0015] The loader includes a frame assembly 1, a power system 2, a cab assembly 3, a working device assembly 4, a hydraulic system 5 and an electrical system 6. The frame assembly 1 is composed of a front frame 1-1 and a rear frame 1-2 structure; the cab assembly 3 is installed in the middle of the frame assembly 1, the power system 2 is installed under the cab assembly 3, and the working device assembly 4 is installed on the front side of the frame assembly 1. A hydraulic system 5 and an electrical system 6 are installed on the device assembly 4. The power system 2 includes an engine 2-1, a gear oil pump 2-6 and a gearbox 2-7. The engine 2-1 is provided with a drive wheel 2-2, and the gear The box 2-7 is connected with the driven wheel 2-4, and the driving wheel 2-2 and the driven wheel 2-4 are connected by an industrial variable speed wide V-belt 2-3; the engine 2-1 and the gear oil pump 2-6 are driven by the oil pump Shafts 2-5 are connected together. The oil pump transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com