Methods of manufacturing monolithic gas generant grains

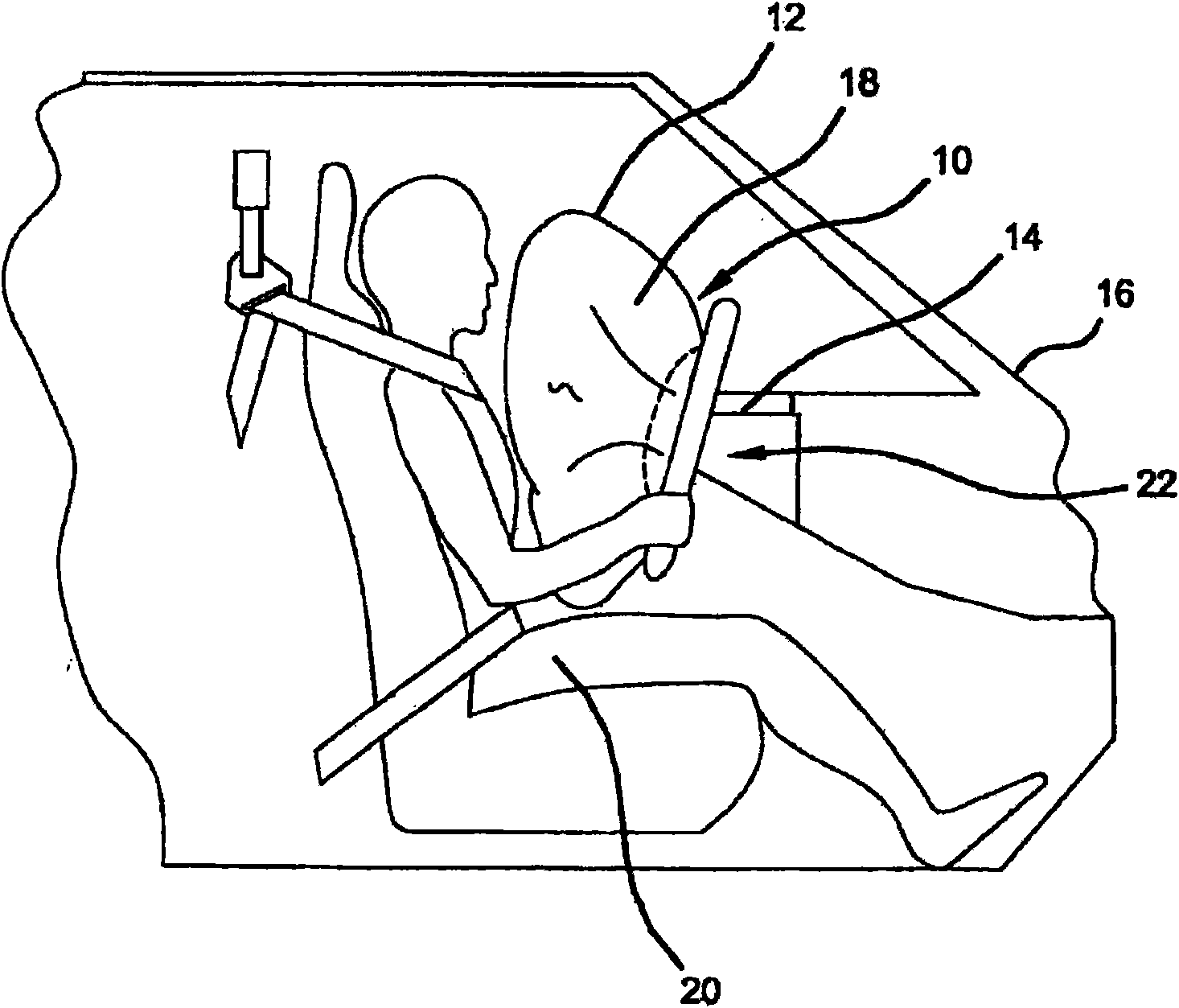

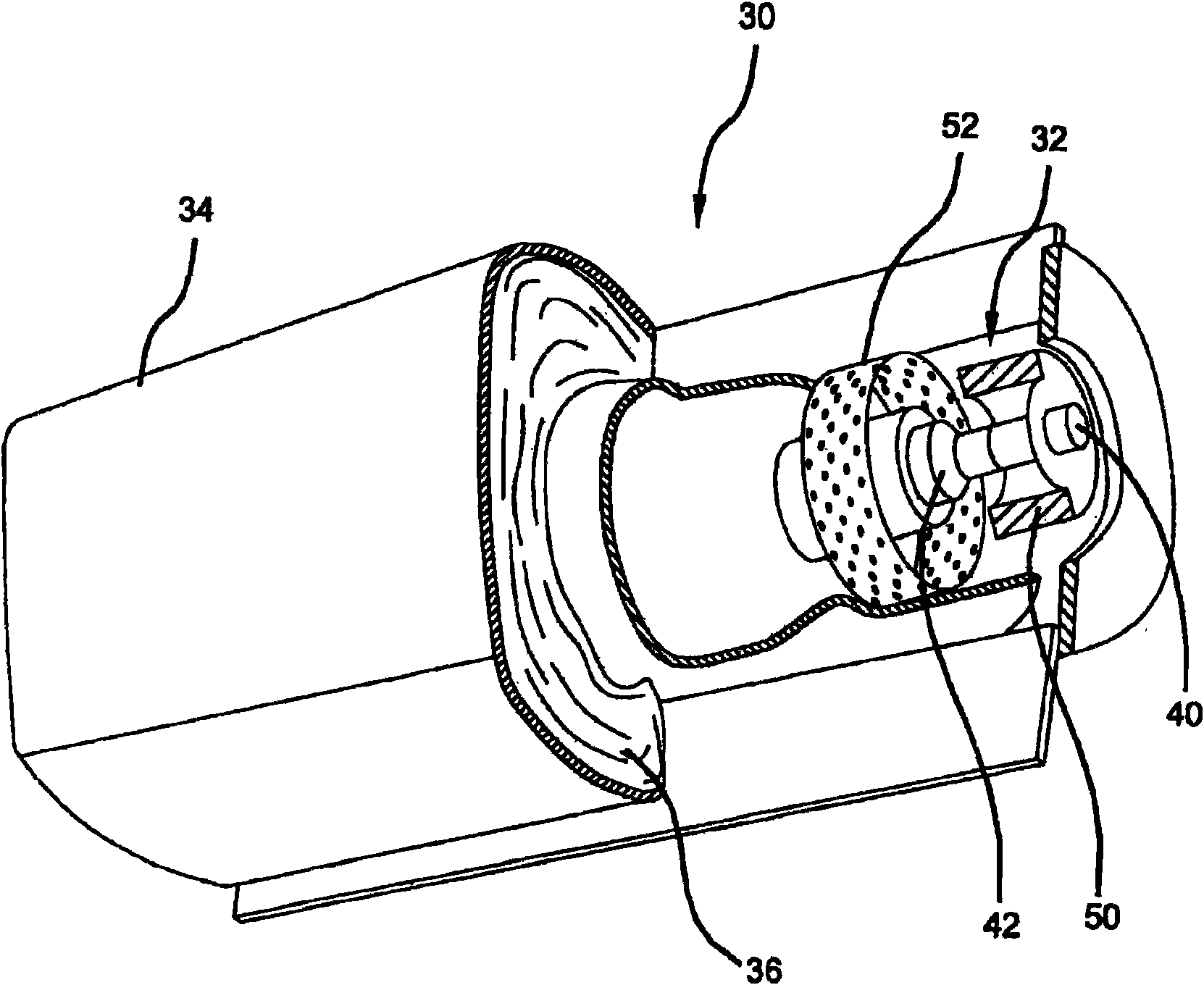

A gas generating agent and gas generation technology, which are applied in the production of compressed gas, extrusion of molds and granulation, explosives, etc., can solve the problem that passengers cannot get the benefits of airbags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

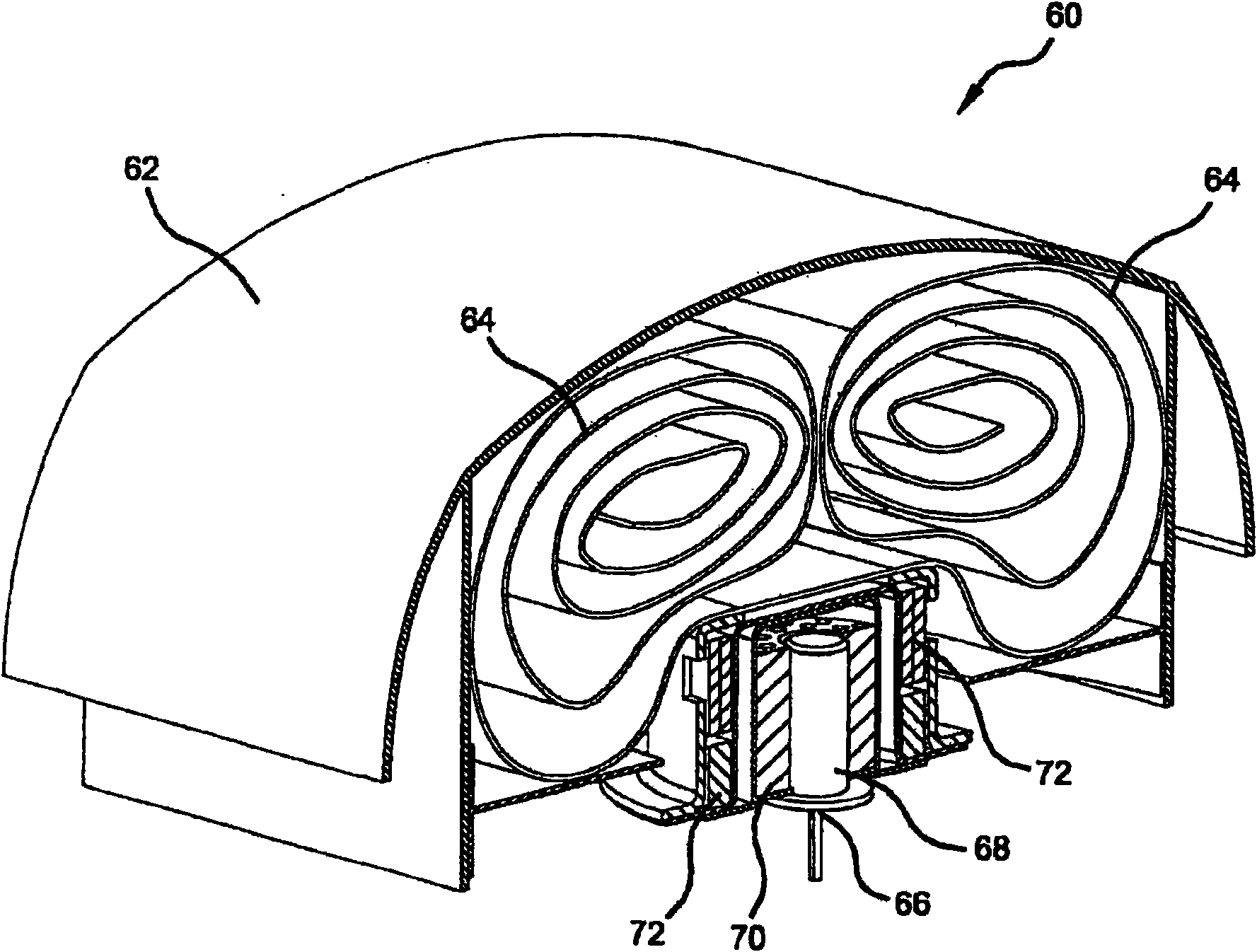

[0080] In one example, a coolant (basic copper carbonate) was dry blended with the spray dried gas generant composition. The blended powder is then compacted by rolling or soft stamping on a rotary pharmaceutical compactor. The mixed powder is compacted by applying a pressure of at least about 40,000 psig (about 275 MPa), and then pelletized to increase its bulk density to achieve proper die filling. Through this procedure, the bulk density is increased to between about 0.75 and about 1.75 g / cc. These pre-pressed powders are then mixed with a release agent such as graphite and placed in a pre-forming die of the desired shape, e.g. Figure 6 An annular disk shape with many holes is shown. The die and powder are placed in a large high tonnage hydraulic press that can exert over 50 tons of force. The raw material is stamped to form a monolithic gas generant solid.

[0081] Various aspects of the present disclosure provide methods of manufacturing monolithic gas generant parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com