Semiconductor module and inverter apparatus

A technology for semiconductors and substrates, which is applied in the field of having a base plate, and can solve the problems of reduced cooling performance and undisclosed composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

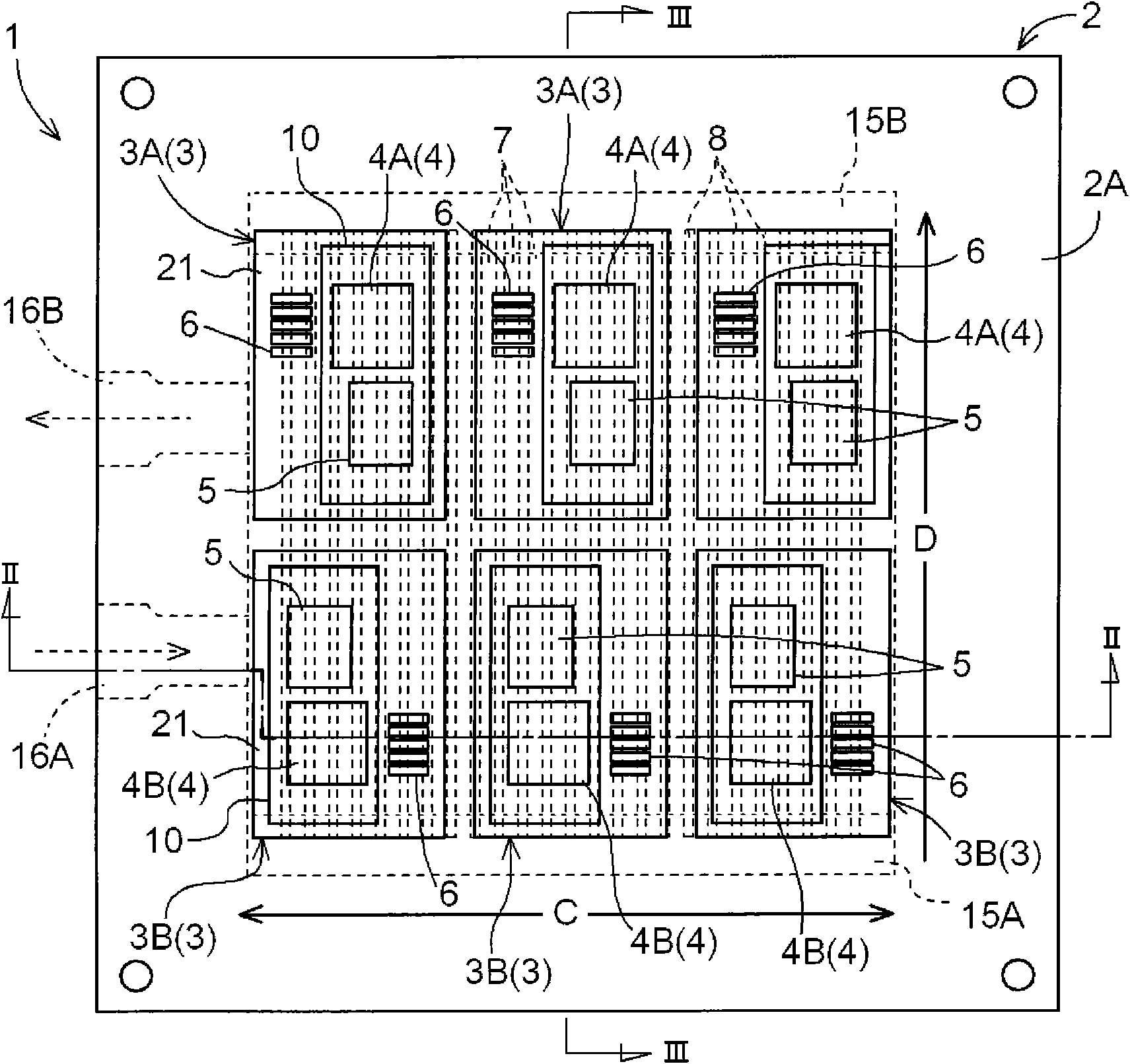

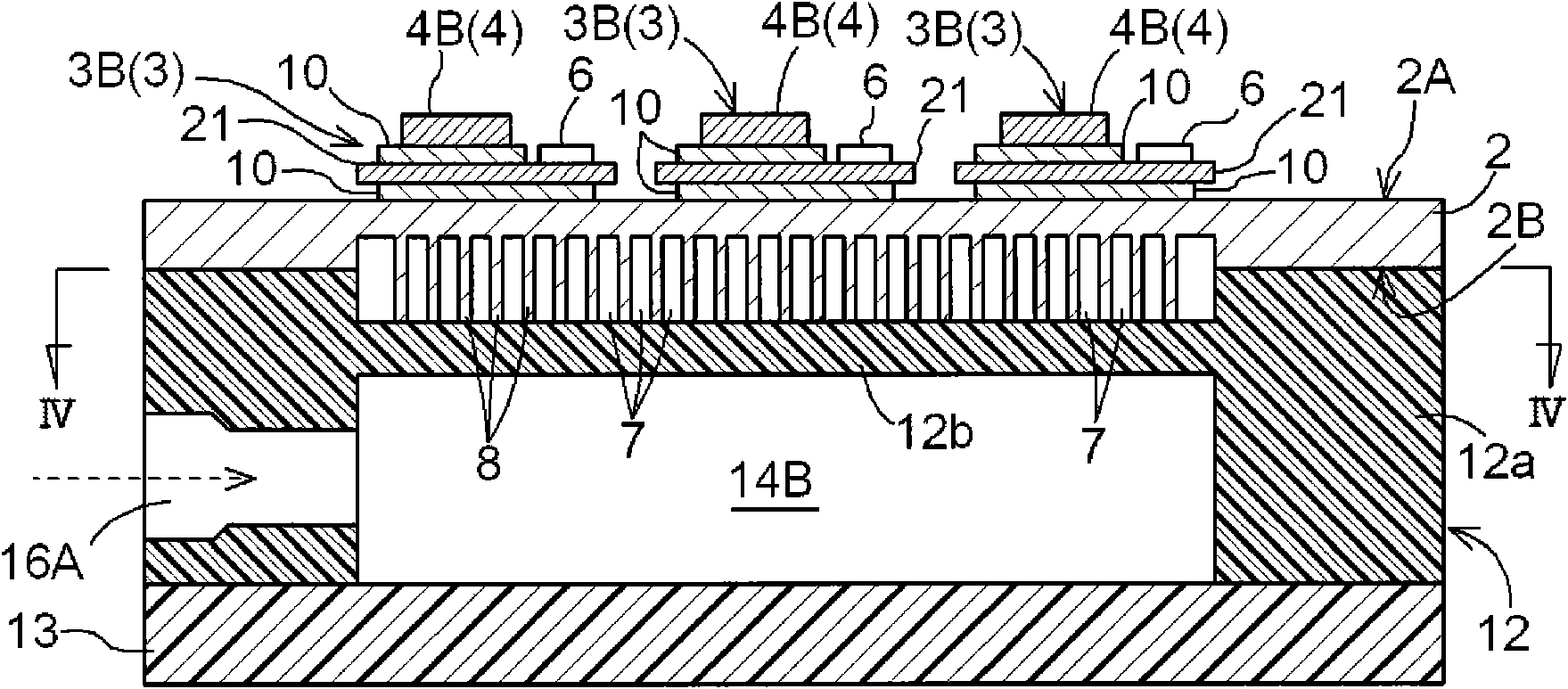

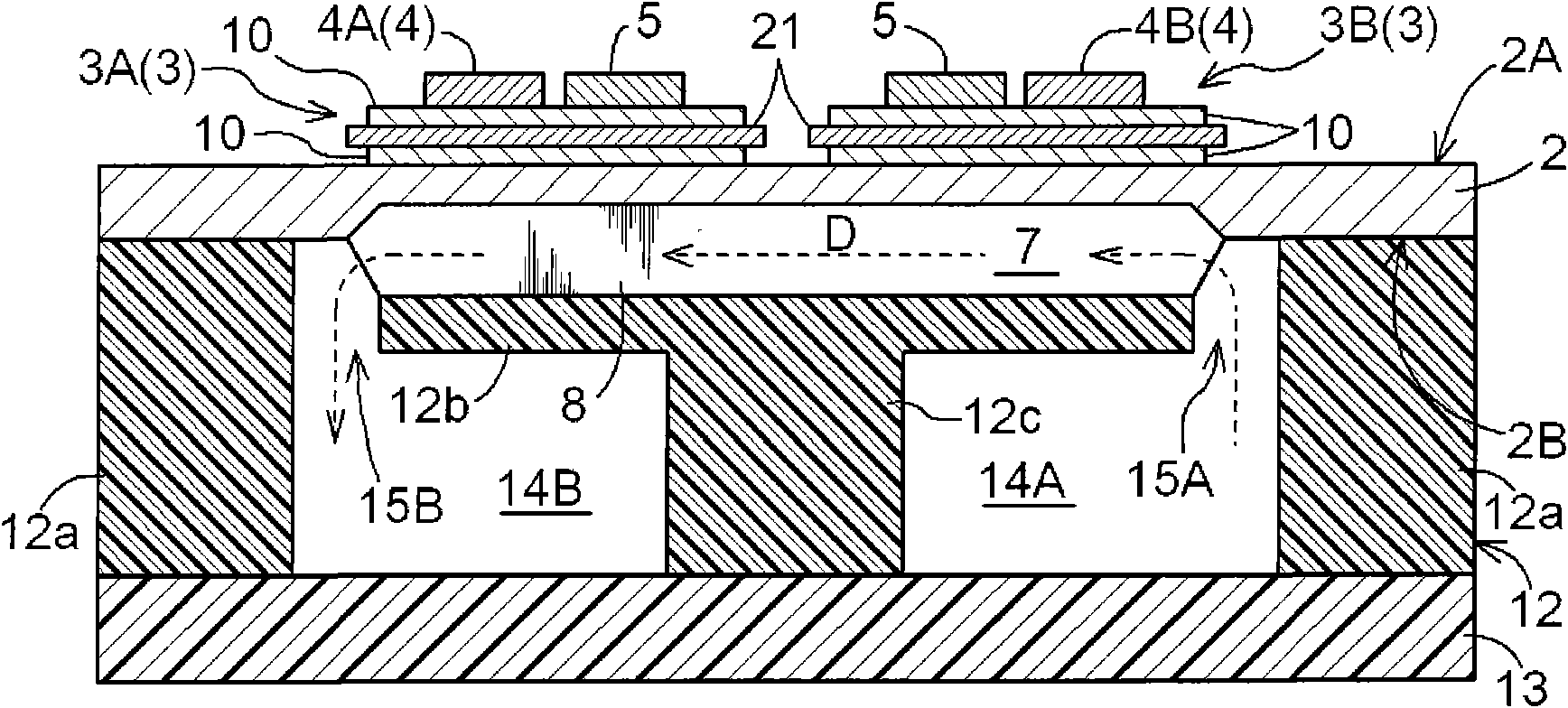

[0041] A first embodiment of the present invention will be described with reference to the drawings. In this embodiment, an example in which the present invention is applied to the semiconductor module 1 as an inverter device constituting a three-phase AC inverter circuit will be described. Figure 1 to Figure 8 It is a figure for demonstrating the structure of the semiconductor module 1 of this embodiment. Also, in Figure 1 to Figure 5 In , configurations other than the substrate 3 above the bottom plate 2 are omitted.

[0042] As shown in these figures, this semiconductor module 1 has a cooling structure including a coolant flow path 7 for cooling the switching element 4 of the substrate 3 placed on the upper surface 2A of the base plate 2, especially the most heat-generating. Allow to cool. Additionally, if Image 6 As shown, this semiconductor module 1 constitutes an inverter circuit 11 for driving a three-phase AC motor 31 . Therefore, if figure 1 As shown, six su...

no. 2 approach

[0070] A second embodiment of the present invention will be described with reference to the drawings. Figure 9 It is a plan view showing the configuration of the main part of the semiconductor module 1 of the present embodiment. As shown in this figure, the semiconductor module 1 of this embodiment is configured such that only one set consisting of a pair of lower arm substrate 3A and upper arm substrate 3B is placed on one base plate 2 . That is, the semiconductor module 1 of this embodiment differs from the above-mentioned first embodiment in the number of substrates 3 mounted on one base plate 2 . In addition, the point which is not specifically demonstrated in this embodiment can be the same as the structure of the said 1st embodiment.

[0071] Therefore, in the semiconductor module 1 of this embodiment, compared with the semiconductor module 1 of the first embodiment, the width in the vertical direction C of the base plate 2 is narrowed, and the overall width W of the c...

no. 3 approach

[0073] A third embodiment of the present invention will be described with reference to the drawings. Figure 10 It is a plan view showing the configuration of the main part of the semiconductor module 1 of the present embodiment. The semiconductor module 1 of this embodiment differs from the above-mentioned first and second embodiments in terms of the arrangement and configuration of the substrate 3 . Here, for the sake of simplification of drawings and the like, as in the above-mentioned second embodiment, only one set of a pair of substrates 3A, 3B is placed on one base plate 2 for description. In the same manner, it is also applicable to a configuration in which a pair of substrates 3A, 3B is used as a set and a plurality of sets of substrates 3 are placed on the bottom plate 2 . In addition, regarding the points not particularly described in this embodiment, the same configuration as that of the above-mentioned first embodiment or second embodiment can be employed.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com