Planetary mill nitrogen protection throttling device

A technology of nitrogen protection and planetary rolling mill, which is applied in metal rolling and other directions, can solve the problems of incomplete prevention of oxidation, ineffectiveness, and increased production costs, and achieve the goals of improving cooling and protection effects, improving production quality, and saving resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

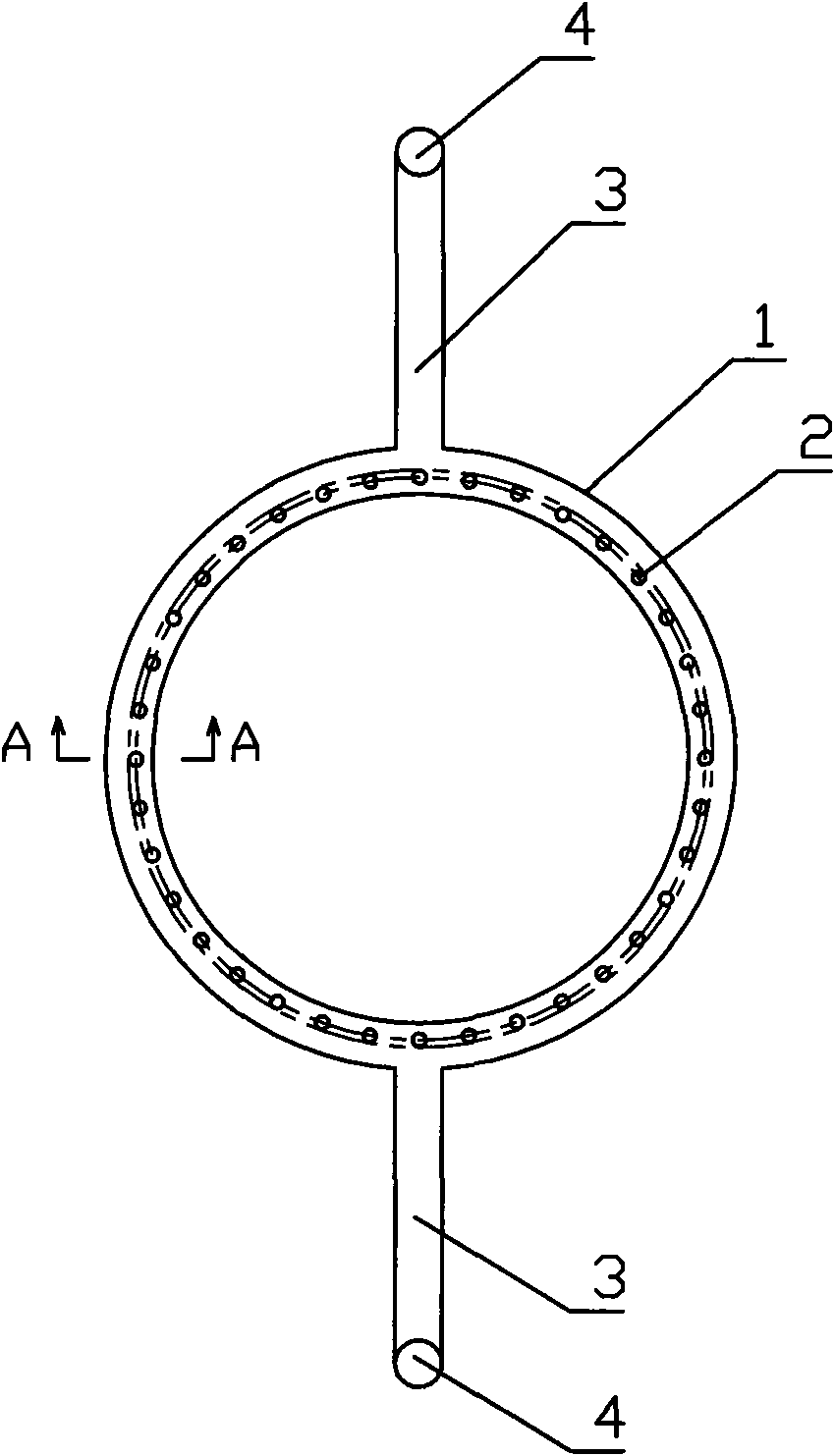

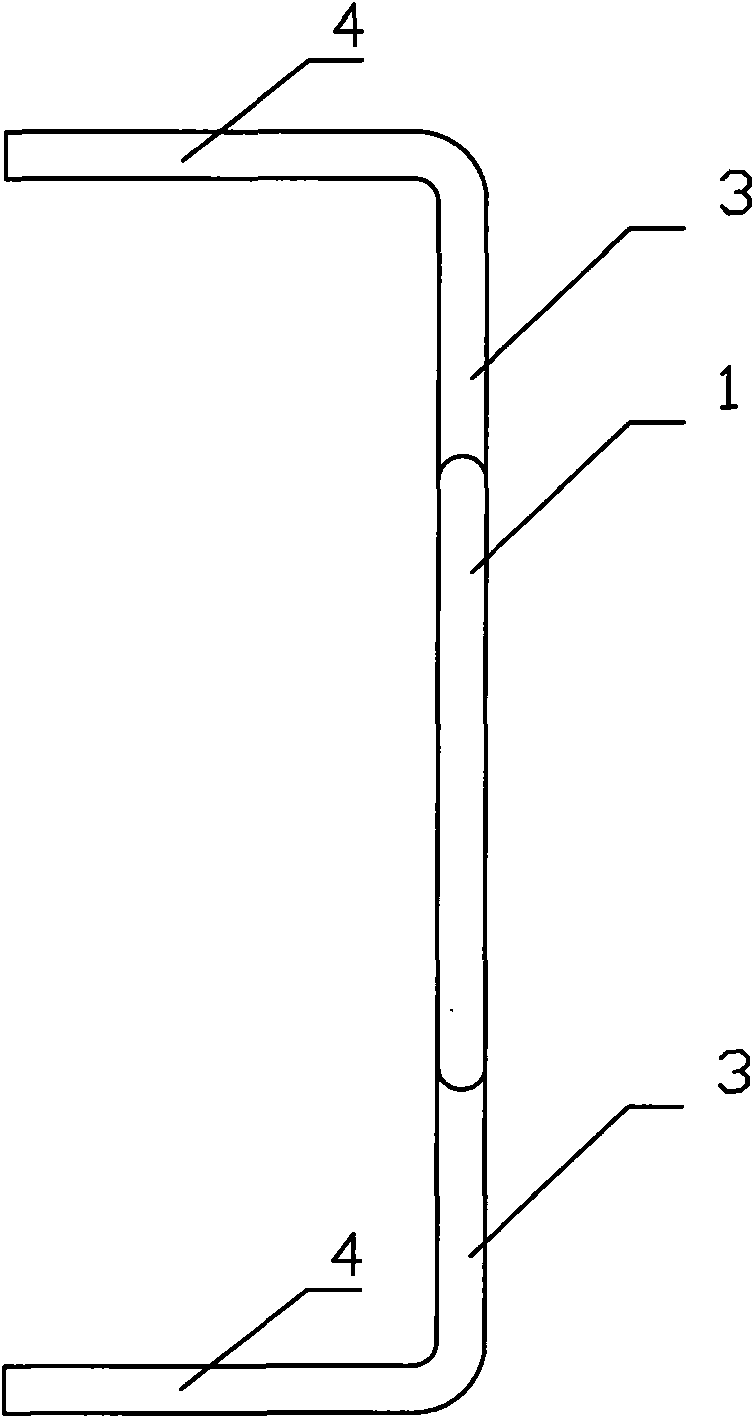

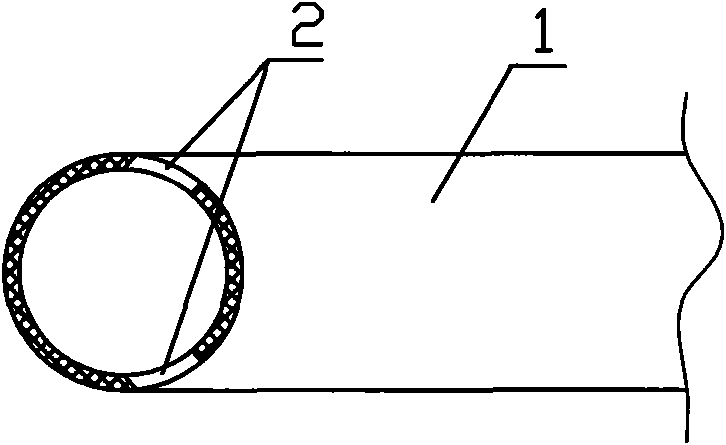

[0017] Such as figure 1 , figure 2 with image 3 As shown, it is an embodiment of the nitrogen protection throttling device for a planetary rolling mill of the present invention, including a throttling ring pipe 1, and a plurality of airflow outlets 2 are arranged on both side walls of the throttling ring pipe 1 in the axial direction, and the airflow outlets 2 face The direction of the axis of the throttle ring (such as image 3 ), the throttle ring pipe is also provided with a connecting pipe 3 for communicating with an external air source, the connecting pipe extends outward from the outer ring wall of the throttle ring pipe 1, and the outer end of the connecting pipe is bent to form a connection with the throttle ring A bent portion 4 parallel to the axis of the tube. The throttling ring tube in this embodiment is a round tube, and may also be a square tube, an oval tube or a polygonal tube. In this embodiment, the connecting pipes are two centrally symmetrically arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com