Three-dimensional curved surface die-pressing forming mold of thin-wall stamping part and press die method thereof

A three-dimensional curved surface, molding technology, applied in the field of metal pressing, can solve the problems of difficult maintenance and high cost, and achieve the effect of easy operation, simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

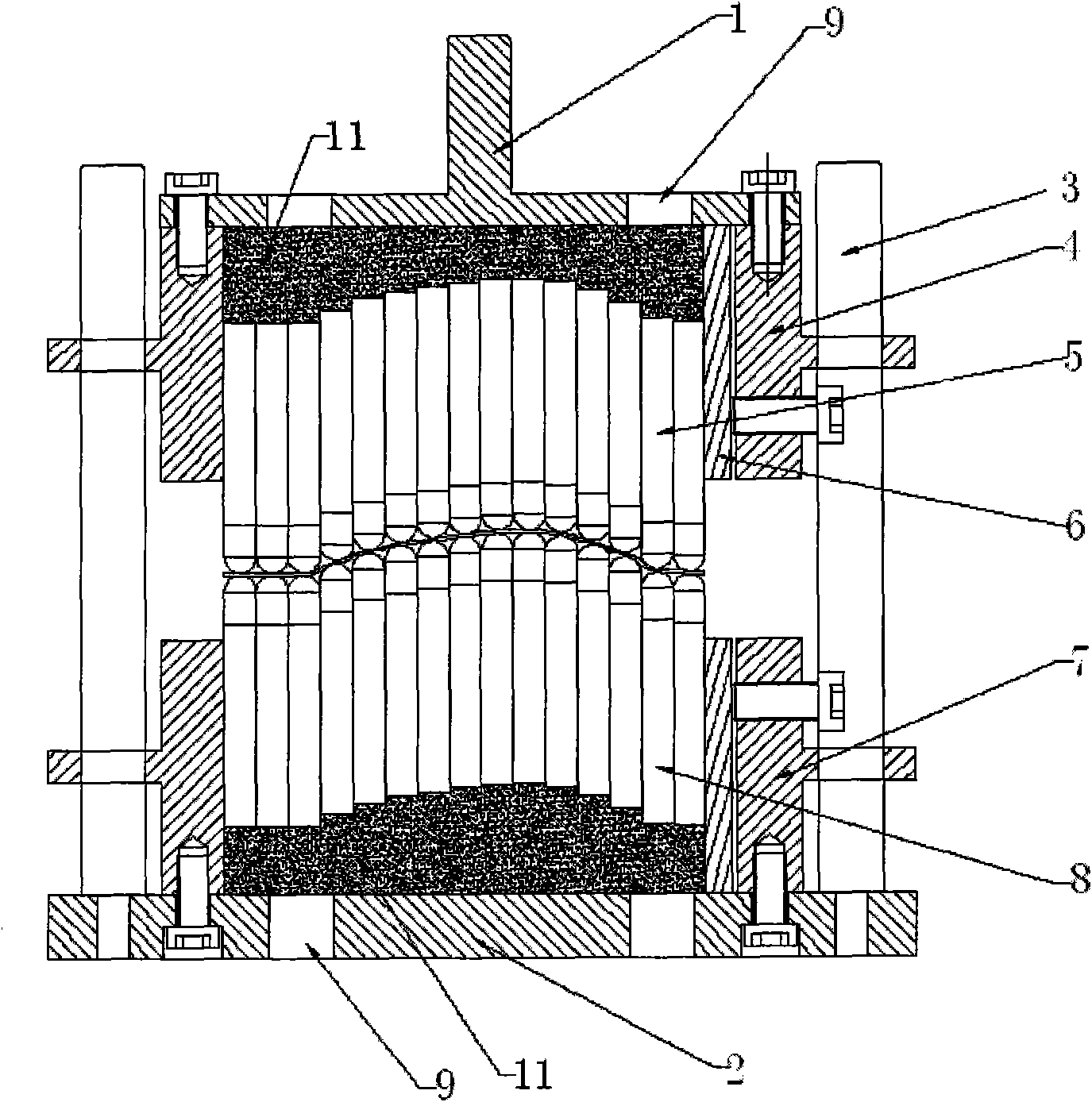

[0026] like figure 1 As shown, the three-dimensional curved surface molding mold for thin-walled sheet metal parts involved in this embodiment includes: an upper mold 1, a lower mold 2 and a guide post 3, wherein: the upper mold 1 and the lower mold 2 are arranged opposite to the guide post respectively 3 active connections.

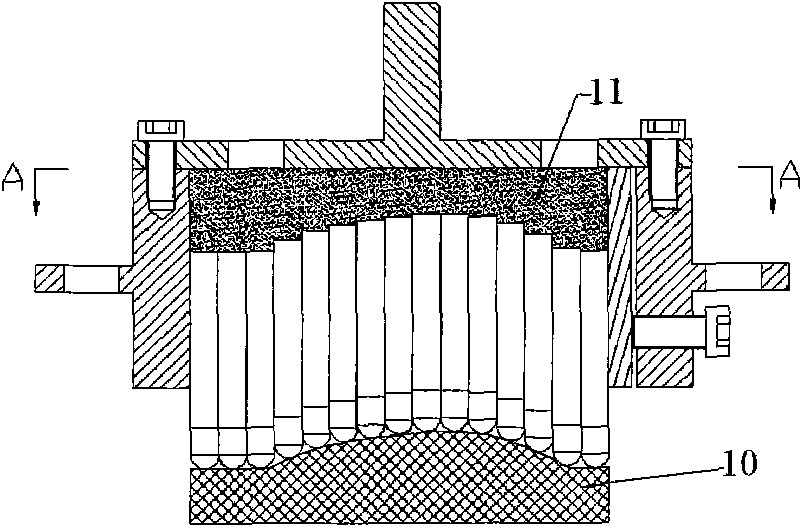

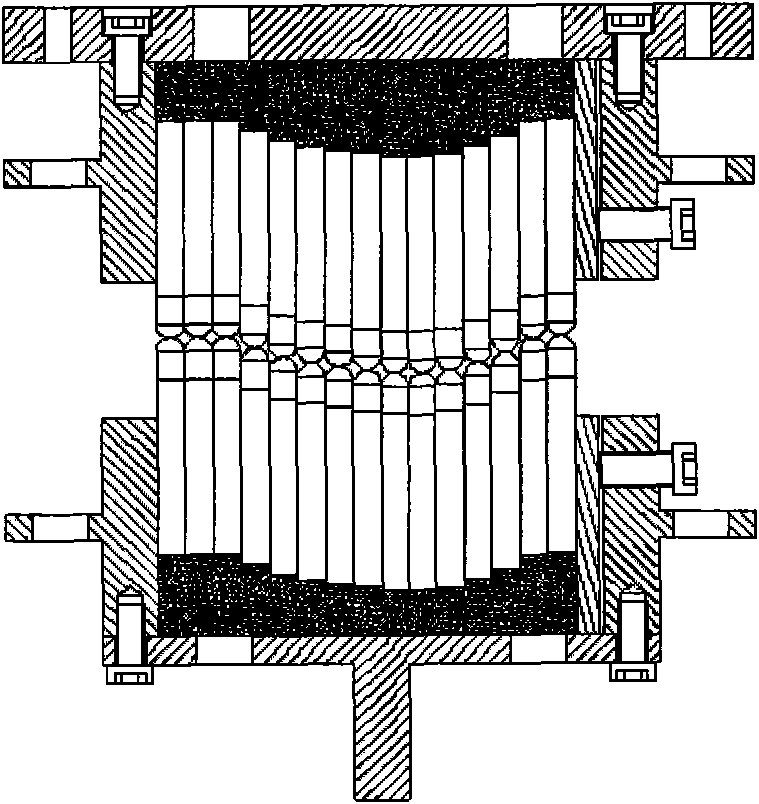

[0027] like figure 2 and Figure 4 As shown, the upper mold 1 includes: an upper mold housing 4 and an upper mold punch 5, wherein: 225 upper mold punches 5 are fixed and vertically arranged in the upper mold housing 4 in a matrix through a fixed frame 6 .

[0028] The lower die 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com