Full-automatic continuous conveying mechanism with automatic compacting device

A technology of a pressing device and a conveying mechanism, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve problems such as unsatisfactory, slow action, and small clamping surface, so as to improve productivity and reduce idle travel time , labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

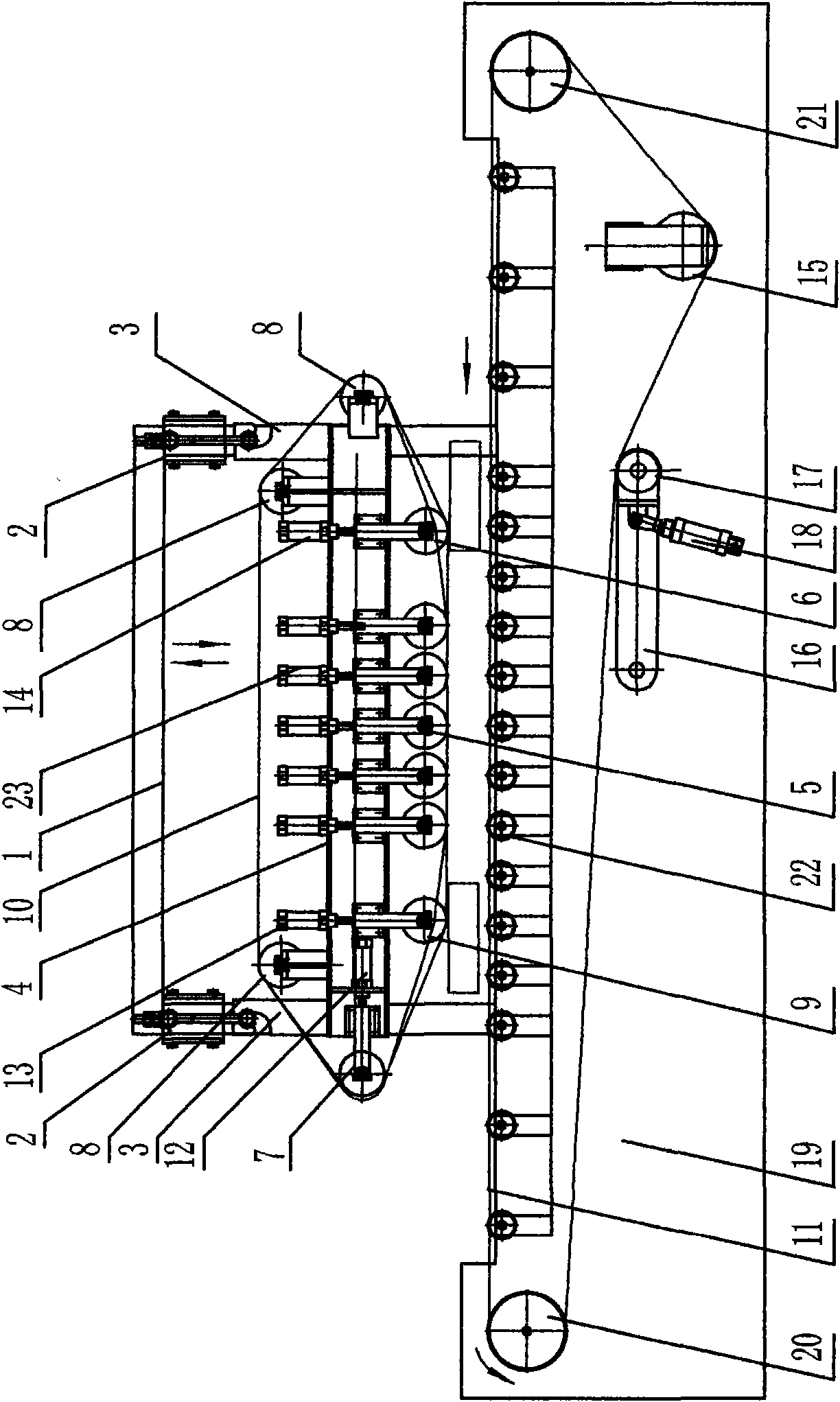

[0013] Referring to the accompanying drawings, the fully automatic continuous conveying mechanism with automatic pressing device includes: a conveying part and an automatic pressing part, and the conveying part includes a conveying frame, a conveying belt, a conveying belt driving roller, a driven roller and a set of Conveyor belt roller composition,

[0014] The conveying mechanism is also provided with a hanger 1 of an automatic pressing device, and the hanger 1 is connected with the automatic pressing device through an adjustable support connection assembly 2 .

[0015] The hanger 1 is used for installing the automatic pressing device, and the adjustable support connection assembly 2 is used for adjusting the position of the automatic pressing device in the vertical direction.

[0016] The automatic pressing device includes: vertical beam 3, crossbeam 4, a group of pressing rollers 5, a first adjustable pressing wheel 6, a second adjustable pressing wheel 9, an adjustable t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com