Preparation method of 4-chlorobutyroyl chloride

A technology of chlorobutyryl and butyrolactone, which is applied in the field of preparation of 4-chlorobutyryl chloride, can solve the problems of easy escape of phosgene, high reaction temperature, and no industrial operation, and achieve simple process and high yield High and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

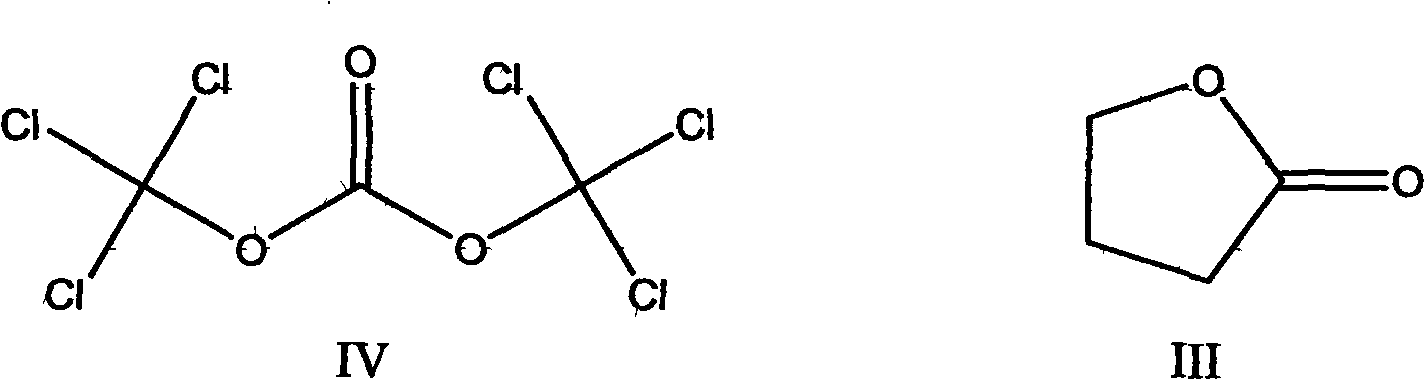

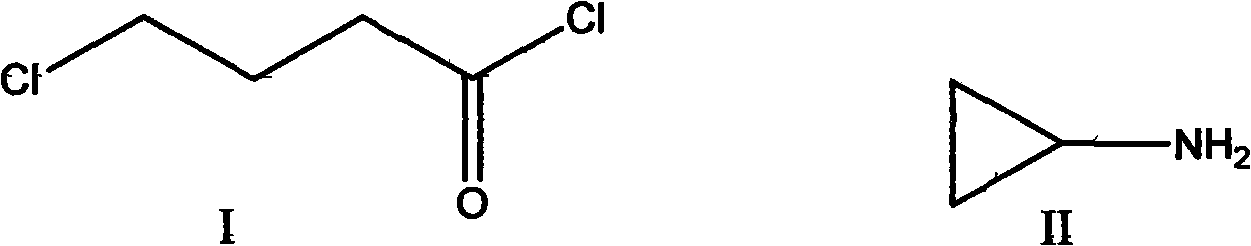

[0036] Add 43g (0.5mol) of γ-butyrolactone and 1.5g of zinc chloride to a 250ml three-neck flask, stir and heat up to 100°C, cool down to room temperature, add 150g (0.505mol) of solid phosgene, heat up to 120°C and keep for 18 hours , and recovered under reduced pressure to obtain 53.1g of 4-chlorobutyryl chloride, with a conversion rate of 75.3%.

Embodiment 2

[0038] Add 43g (0.5mol) of γ-butyrolactone, 1.5g of zinc chloride, and 1 drop of DMF into a 250ml three-neck flask, stir and heat up to 100°C, cool down to room temperature, add 75g (0.253mol) of solid phosgene, and heat up to 100°C After 10 hours of heat preservation, 55.62 g of 4-chlorobutyryl chloride was recovered under reduced pressure, with a conversion rate of 78.9%.

Embodiment 3

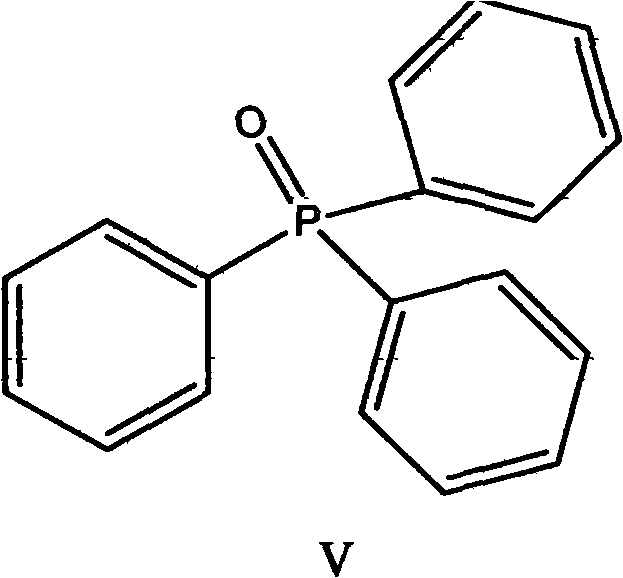

[0040] Add 43g (0.5mol) of γ-butyrolactone, 1.2g of zinc chloride, and 0.02g of triphenylphosphine oxide into a 250ml three-necked flask, stir and heat up to 100°C, cool down to room temperature, and add 75g (0.253mol) of solid phosgene , raised the temperature to 90° C. for 15 hours, and recovered under reduced pressure to obtain 57.88 g of 4-chlorobutyryl chloride, with a conversion rate of 82.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com