Hollow sandwich filled steel tubular column-steel beam connection adopting one-way fastening bolt

A technology of steel pipe concrete columns and one-way bolts, which is applied in construction, building construction, etc., can solve problems such as restrictions on the use of ordinary bolts, and achieve the effects of avoiding a large amount of work and residual deformation, convenient processing, and simple and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

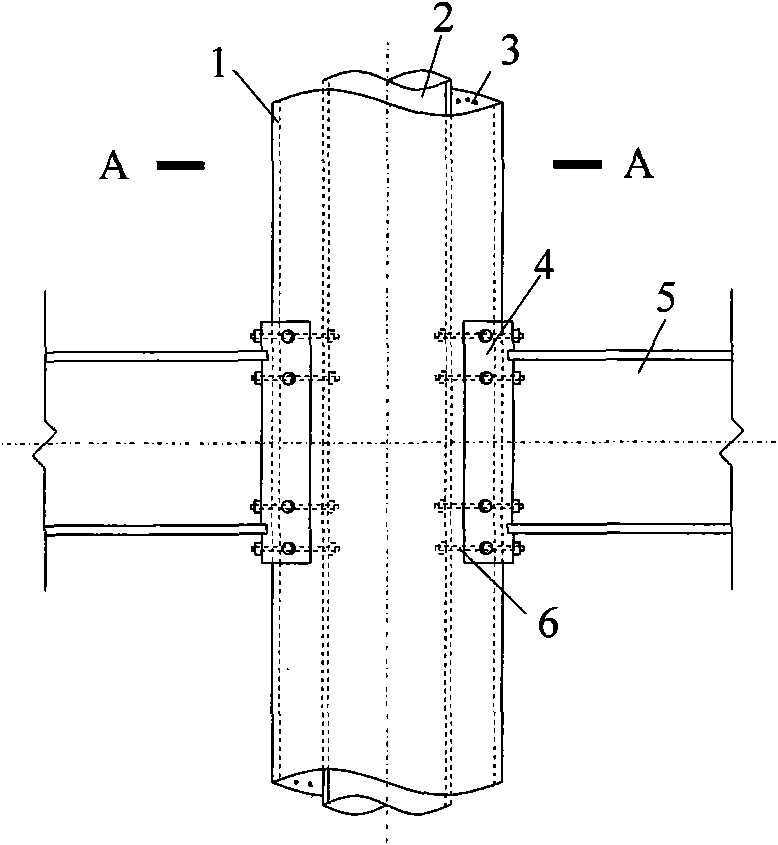

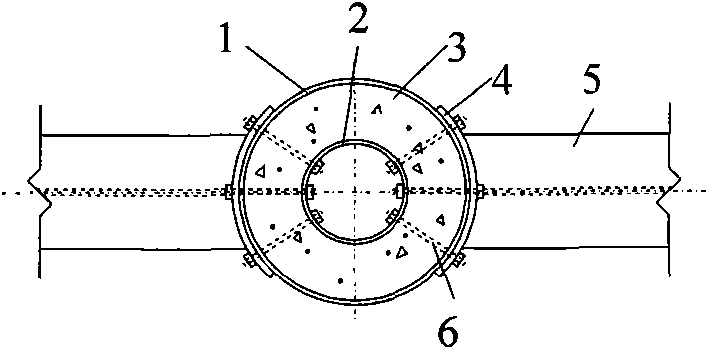

[0023] The structure diagram of this embodiment is as figure 1 and figure 2 Show. The cross sections of the outer steel pipe 1 and the inner steel pipe 2 are circular, the end plate assembly 4 is an arc-shaped end plate, and the steel beam 5 is an I-shaped steel beam. The one-way fastening bolt assembly 6 passes through the holes reserved on the outer steel pipe 1 and the inner steel pipe 2 and is tightened; hoist the steel beam 5 to the designated position, one end of the end plate assembly 4 is close to the pipe wall of the outer steel pipe 1, and the other The side is connected to the steel beam 5, and the end plate assembly 4 and the steel beam 5 are fixed to the outer steel pipe 1 and the inner steel pipe 2 with the one-way fastening bolt assembly 6, and then the interlayer concrete 3 is poured to complete the construction of the node.

Embodiment 2

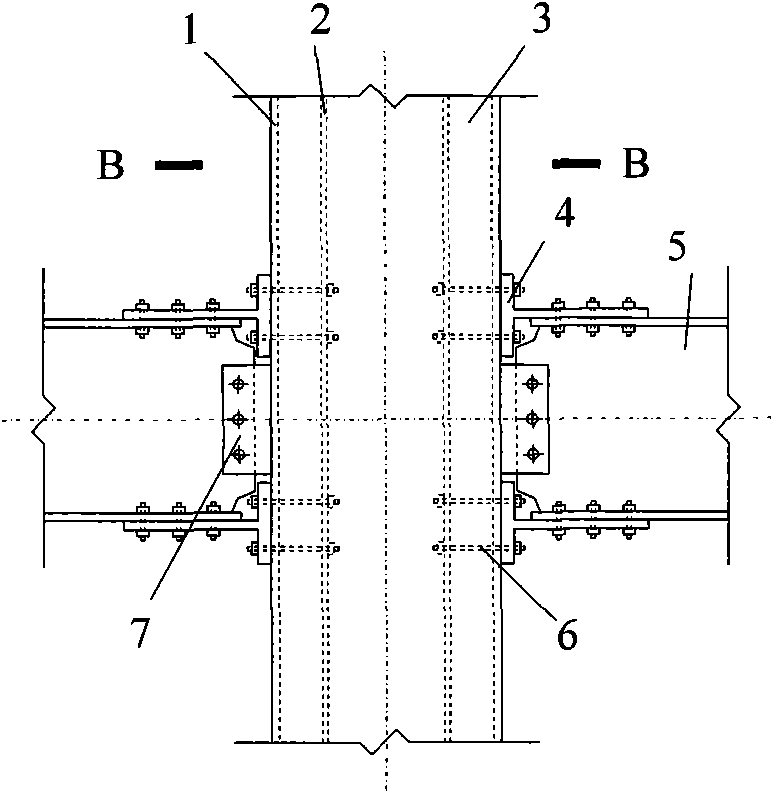

[0025] The structure diagram of this embodiment is as image 3 and Figure 4 Show. The difference from Example 1 is that both the inner steel pipe 2 and the outer steel pipe 1 in this embodiment use square steel pipes, the end plate assembly 4 is T-shaped, and the outer steel pipe wall is welded with a shear web 7, and the end plate assembly 4 The 5 steel beams are connected by bolts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com