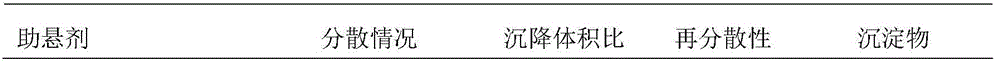

Patents

Literature

39results about How to "Does not affect pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

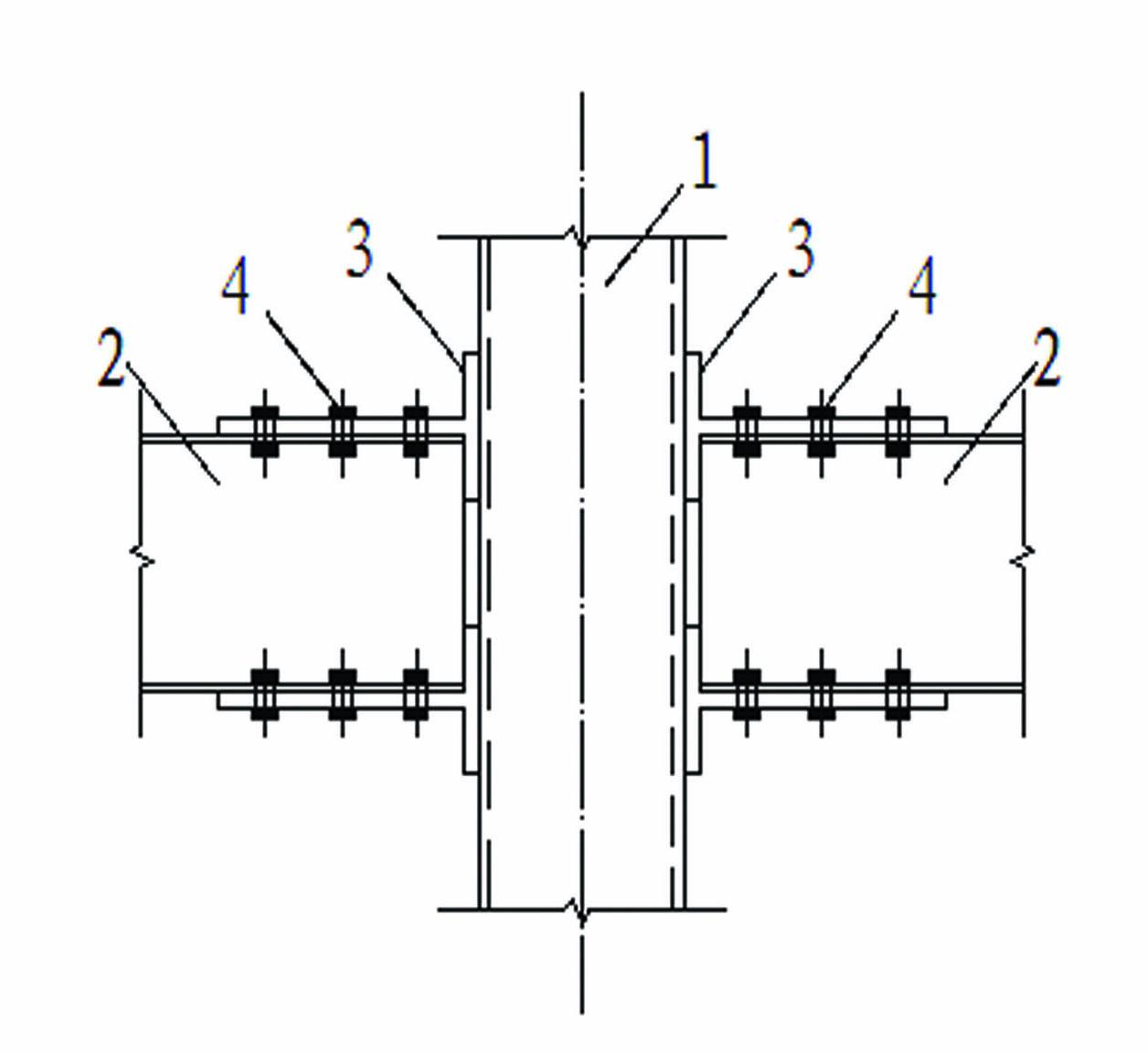

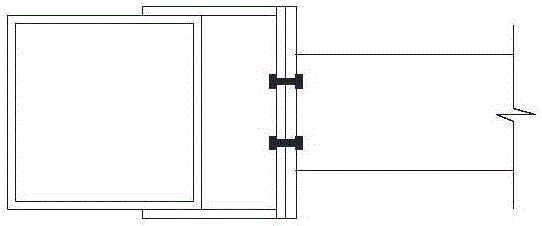

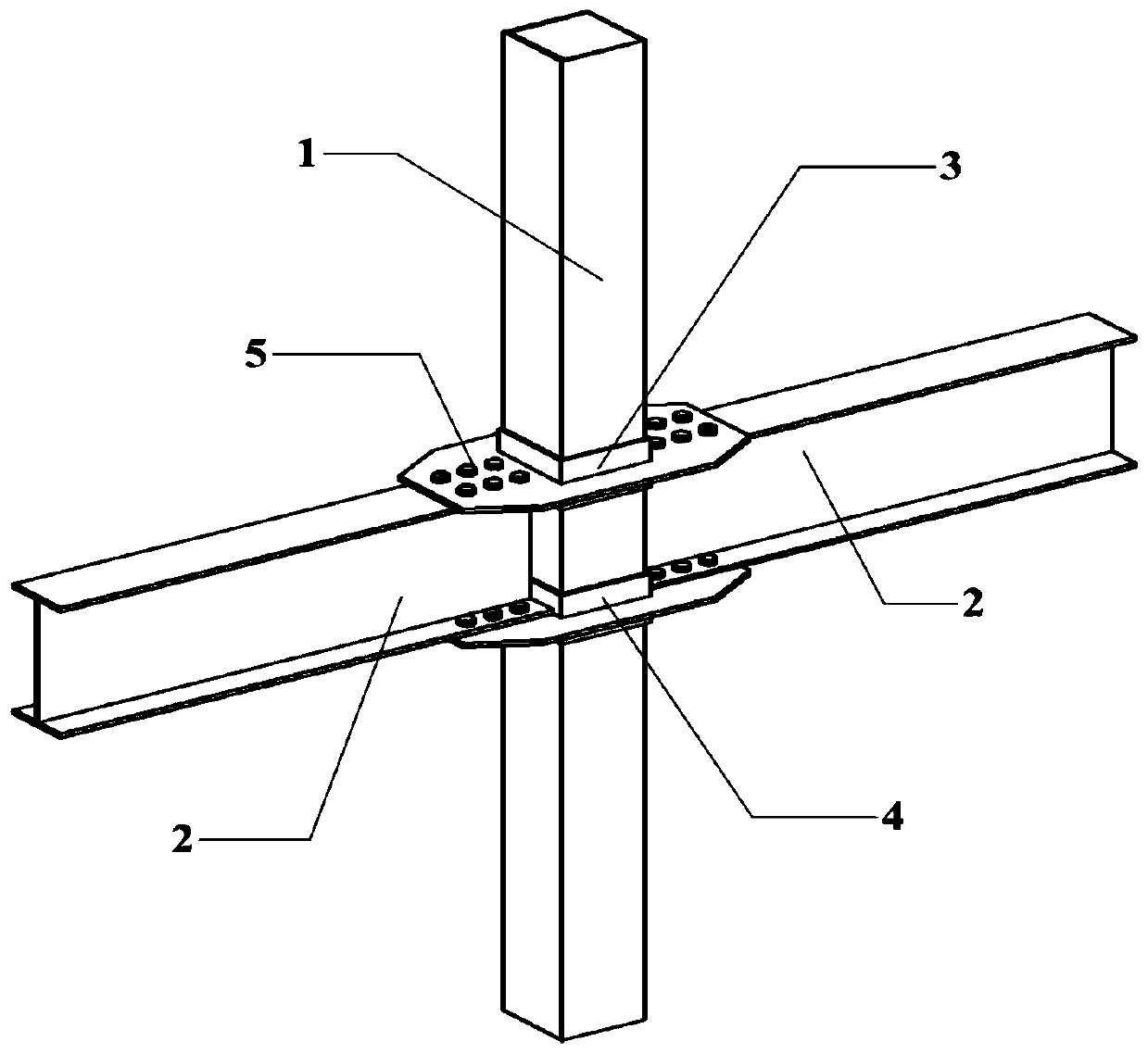

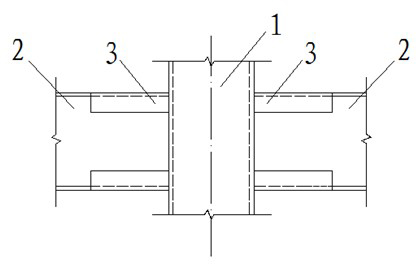

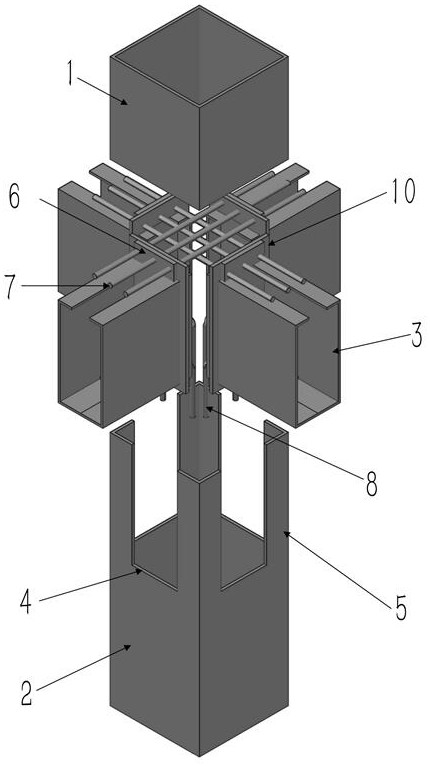

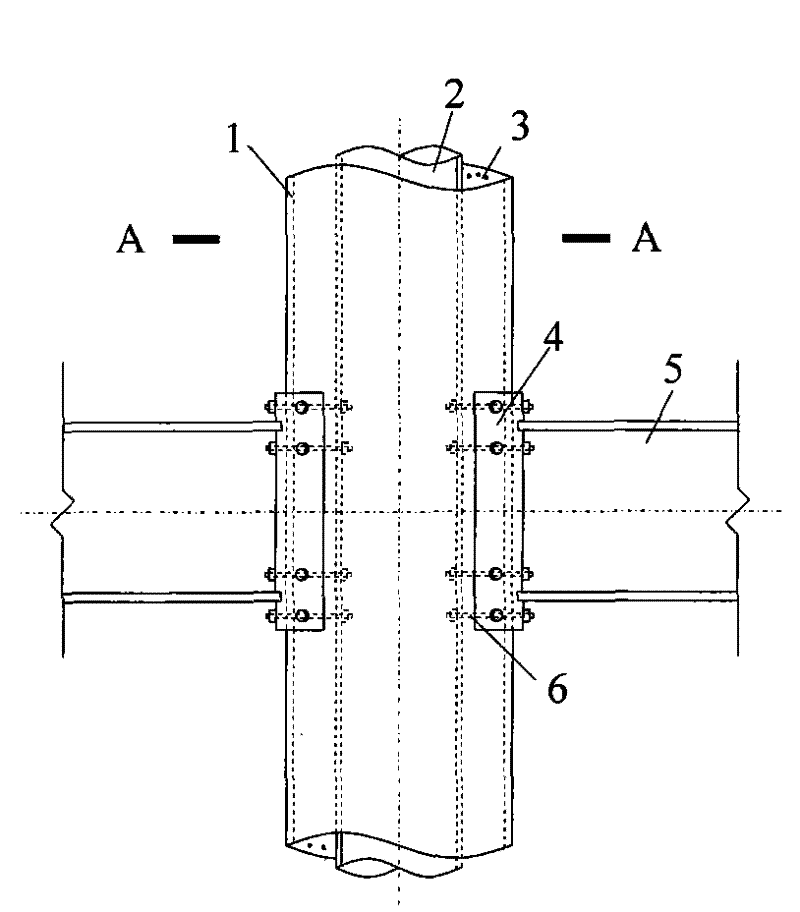

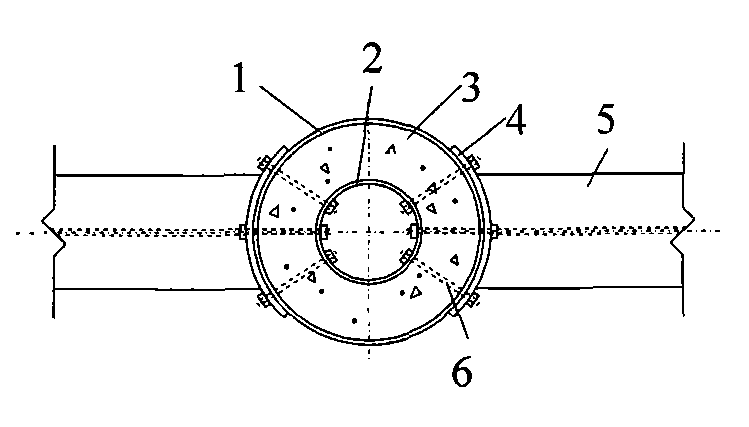

Connecting node of square steel pipe column and H-shaped steel beams

InactiveCN102635166APrevent local bucklingImprove the shortcomings of insufficient stiffnessBuilding constructionsFloor slabShock resistance

The invention relates to a connecting node of a beam and a column of building steel structures, in particular to a connecting node of a square steel pipe column and H-shaped steel beams for multi-layer and high-rise steel structures. The connecting node comprises a square steel pipe column, H-shaped steel beams and T-shaped steels; the T-shaped steels are arranged on the lateral wall of the square steel pipe column and the upper and lower wing edges of the H-shaped steels; webs of the T-shaped steels are connected with the wing edges of the H-shaped steel beams; and the wing edges of the T-shaped steels are fixedly connected with the lateral walls of the square steel pipe column. According to the connecting node of the square steel pipe column and the H-shaped steel beams, the connecting node is simple in structure, and the problem of construction difficulty in installing an internal separating plate is solved; a plastic hinge shifts outwards and better shock-absorbing property is achieved; the construction of an upper floor and the casting of concrete in the square steel pipe are not influenced; and the steel consumption is low. Therefore, the connecting node has high economic and social benefits.

Owner:SHENYANG JIANZHU UNIVERSITY

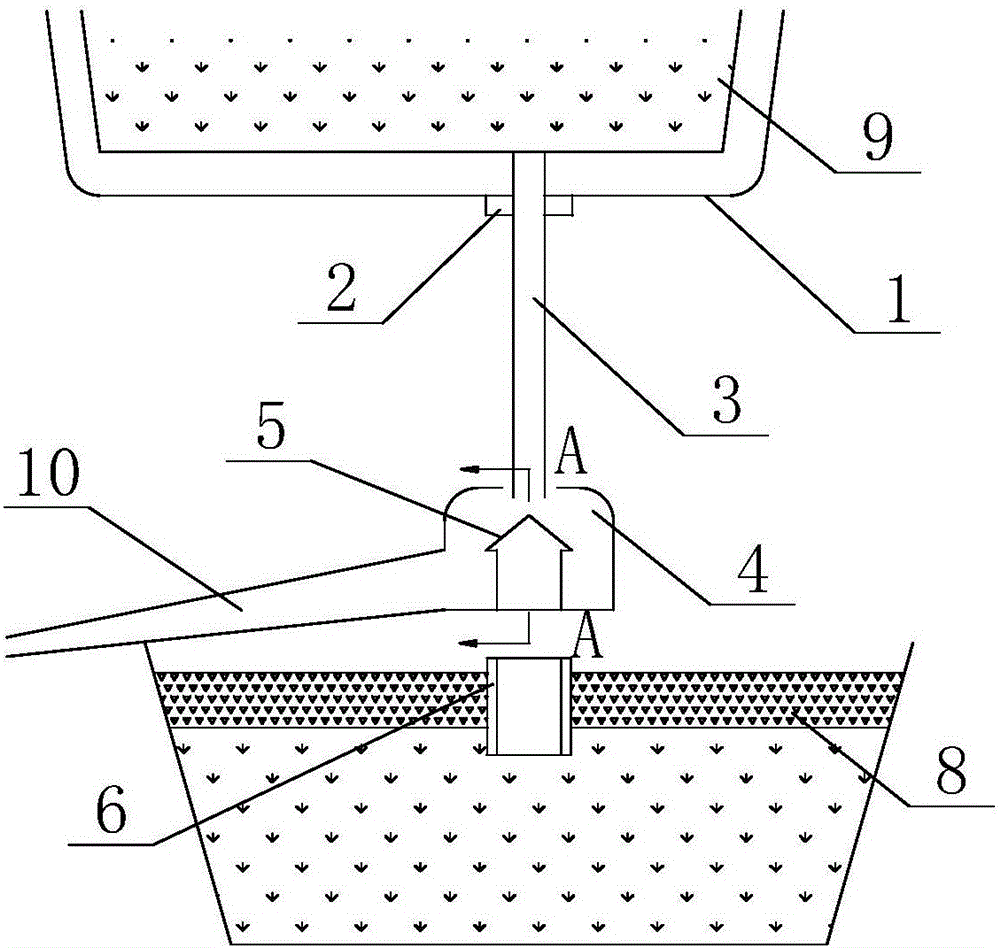

Method and device for keeping molten steel clean in casting of continuous casting ladle

The invention relates to a method and a device for keeping molten steel clean in casting of a continuous casting ladle. When the ladle is cast, a slide water port is opened; a drainage agent flows out from the slide water port, flows onto a casting cap by a long water port of a middle ladle, and flows into a recoverer for recovery along the upper surface of the casting cap; after the drainage agent flows, the molten steel flows down; one part of the molten steel mixed with the drainage agent flows into the drainage agent recoverer along the upper surface of the casting cap; then, the casting cap is corroded by the molten steel for leaking, and the molten steel flows down; after one pot of steel is cast, the long water port is pulled out from the molten steel to deviate from the surface of middle ladle slag; a slag separator is pressed into the molten steel of the middle ladle through middle ladle slag; the side wall of the slag separator is pressed into the molten steel to stop the middle ladle slag from entering the slag separator; and the recoverer is replaced for casting a next ladle. The method and the device have the following advantages: the whole structure is simple; the operation is convenient; the drainage agent and the middle ladle slag can be effectively prevented from mixing into the molten steel of the middle ladle in casting of the ladle; the inclusion in steel is reduced; the steel quality is stable; and the variety quality is stable.

Owner:鞍山市华兴冶金炉料有限公司

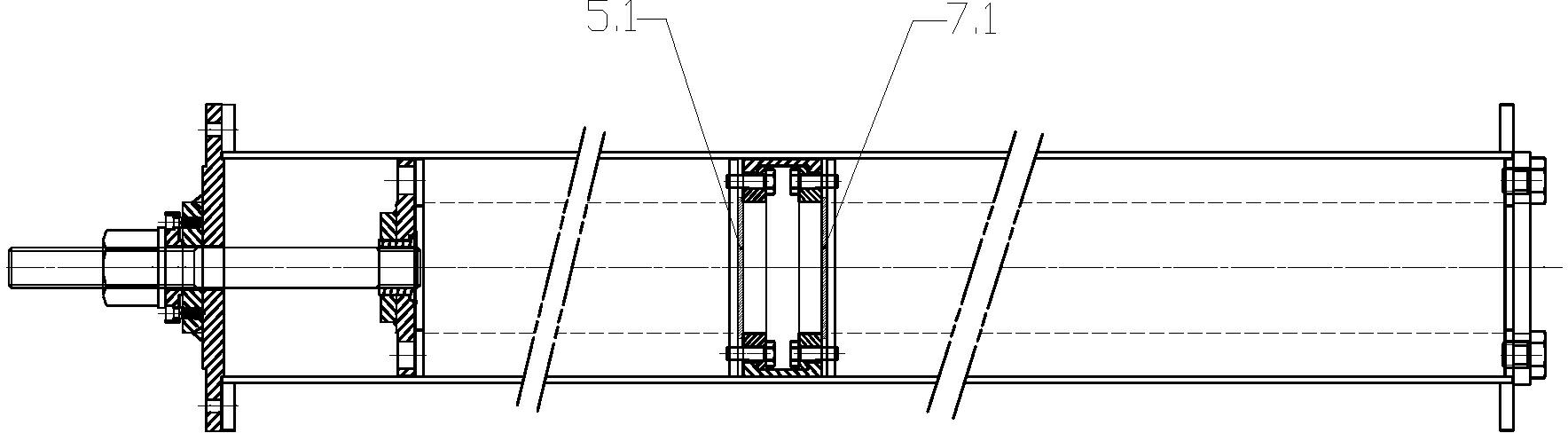

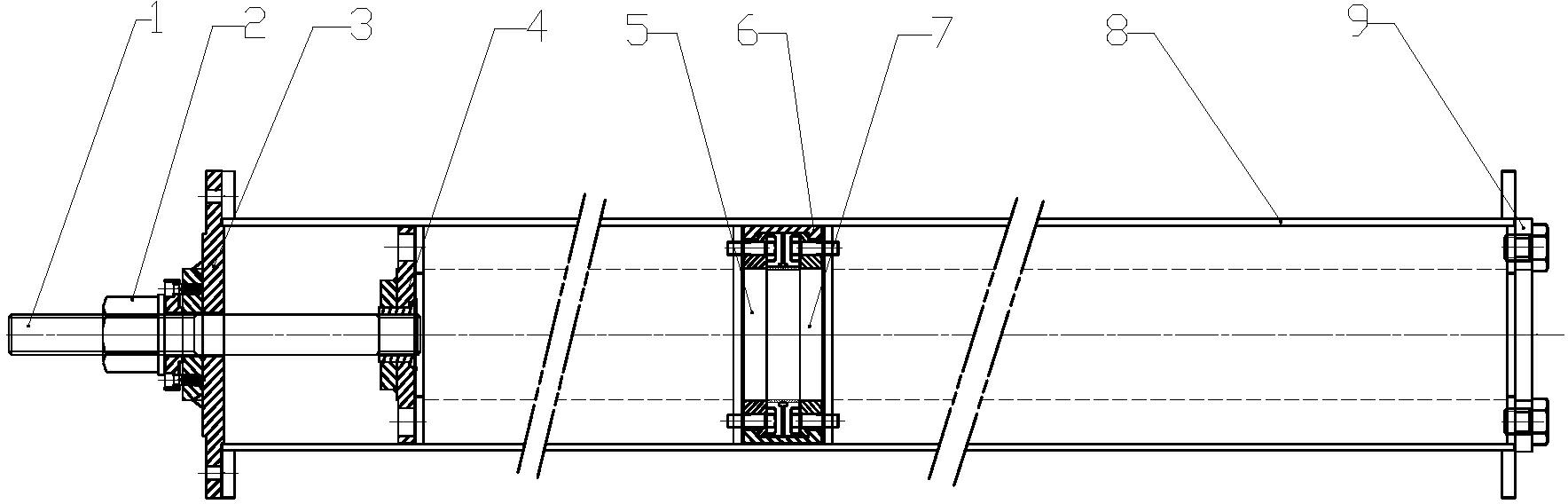

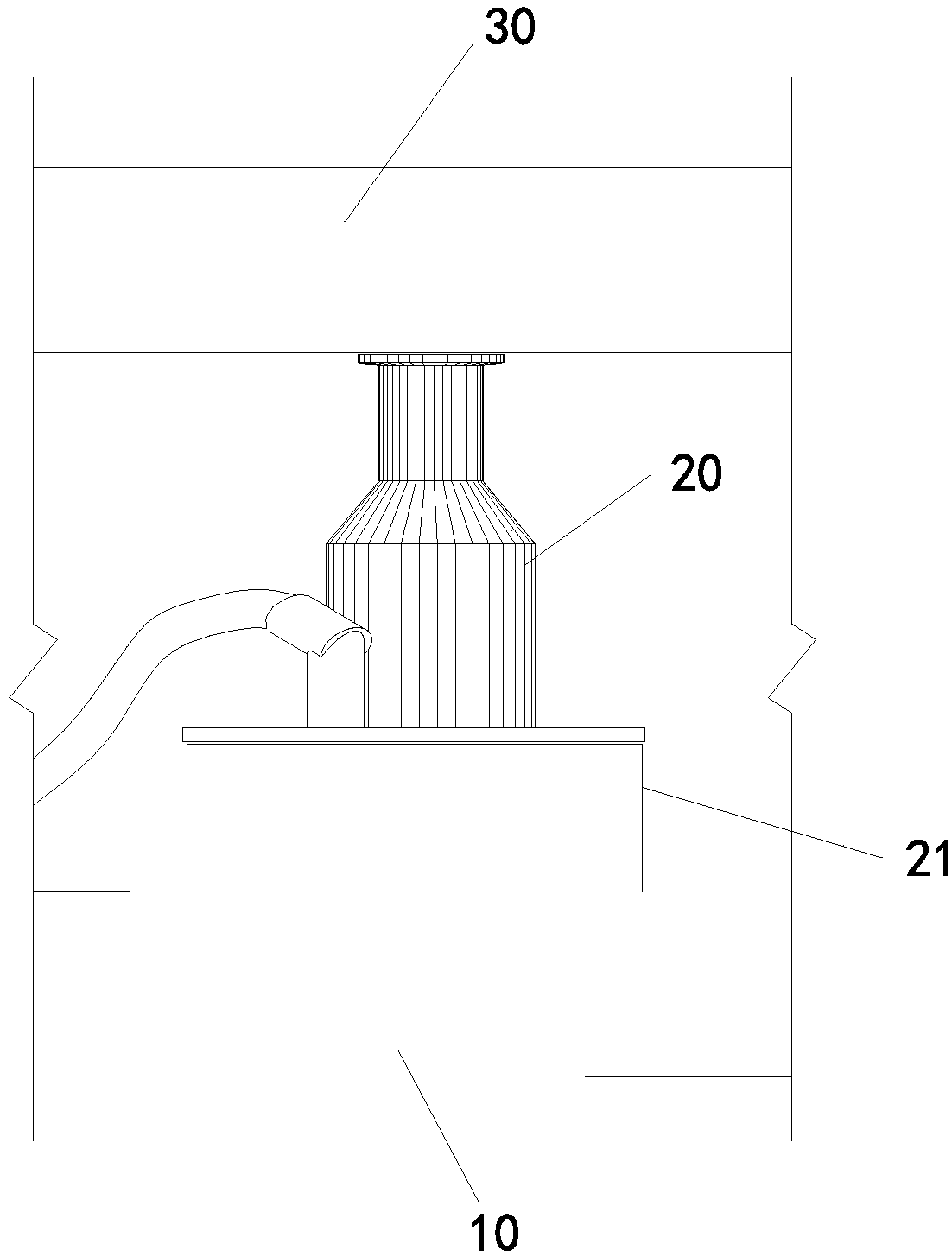

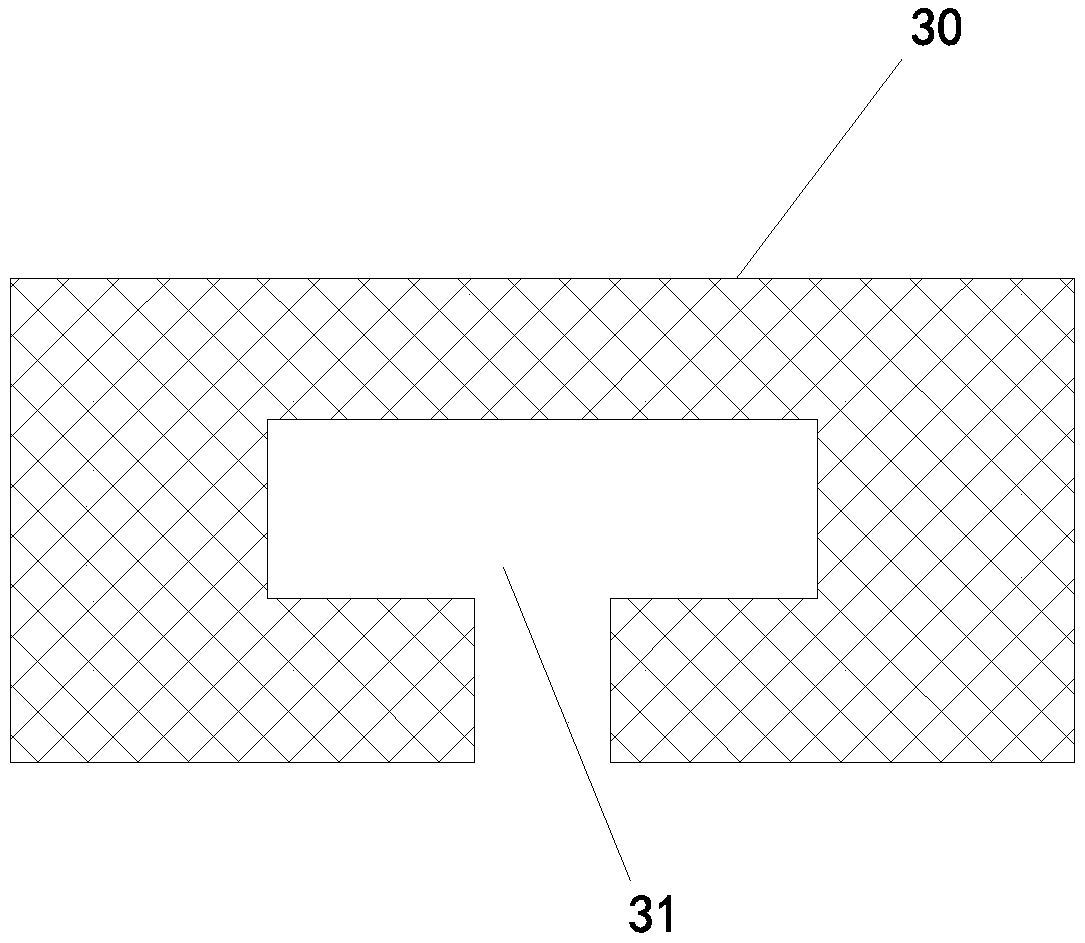

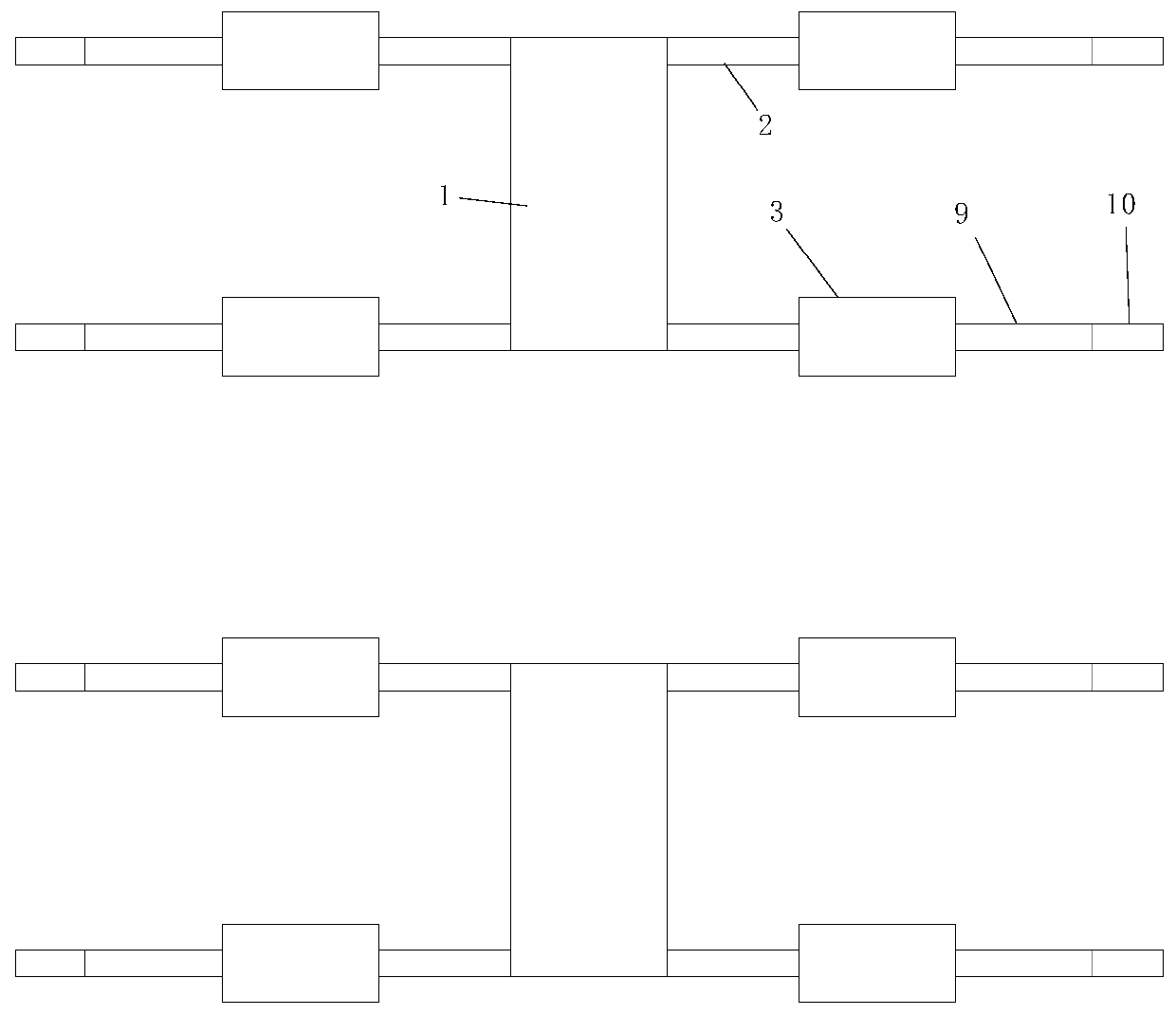

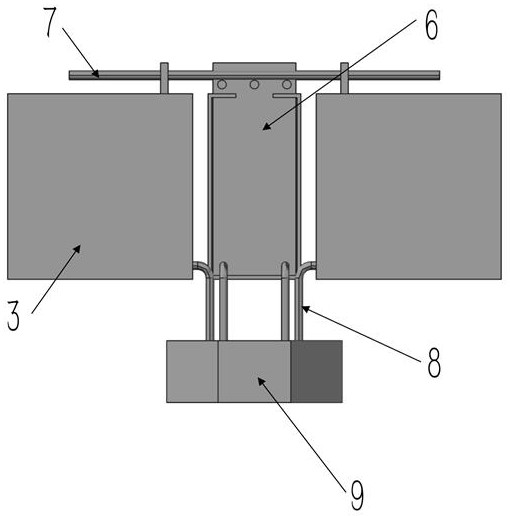

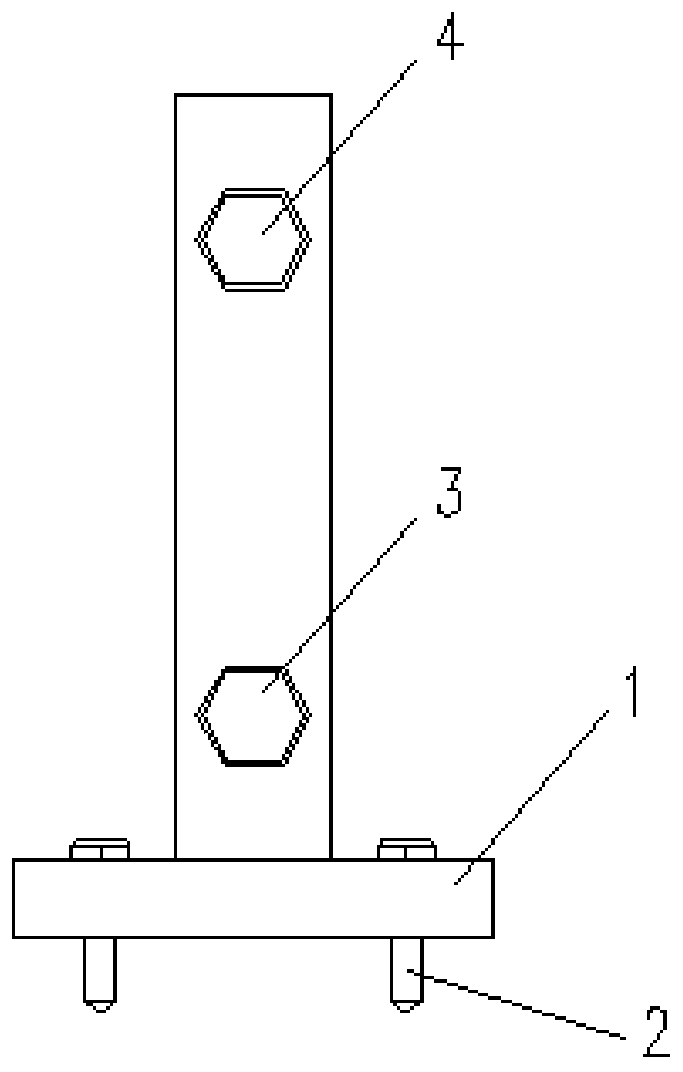

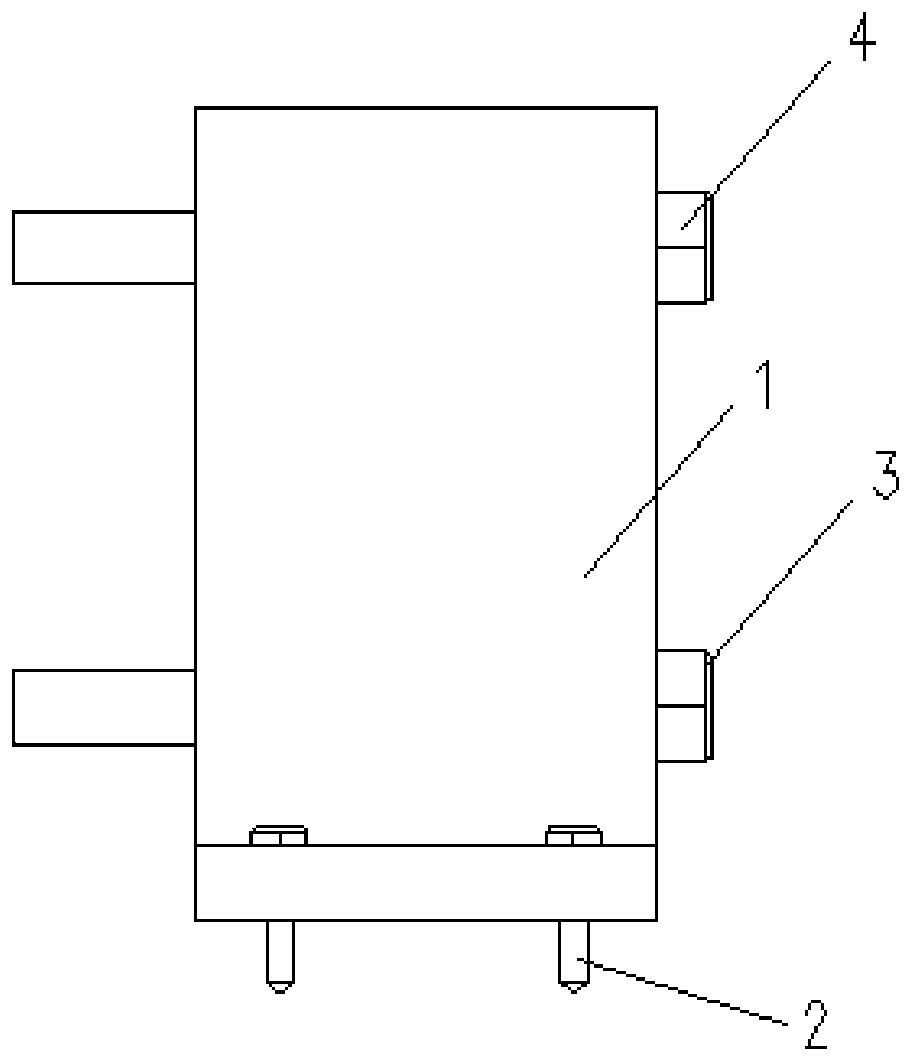

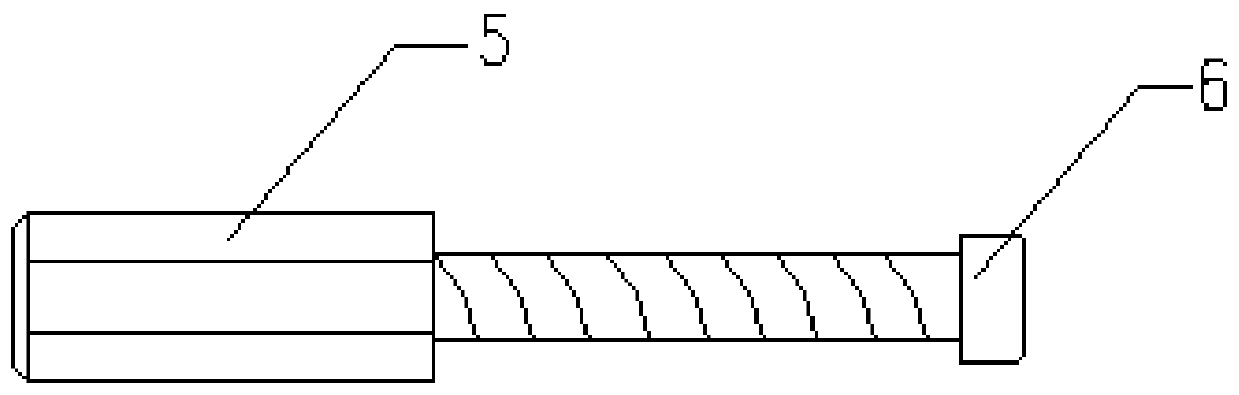

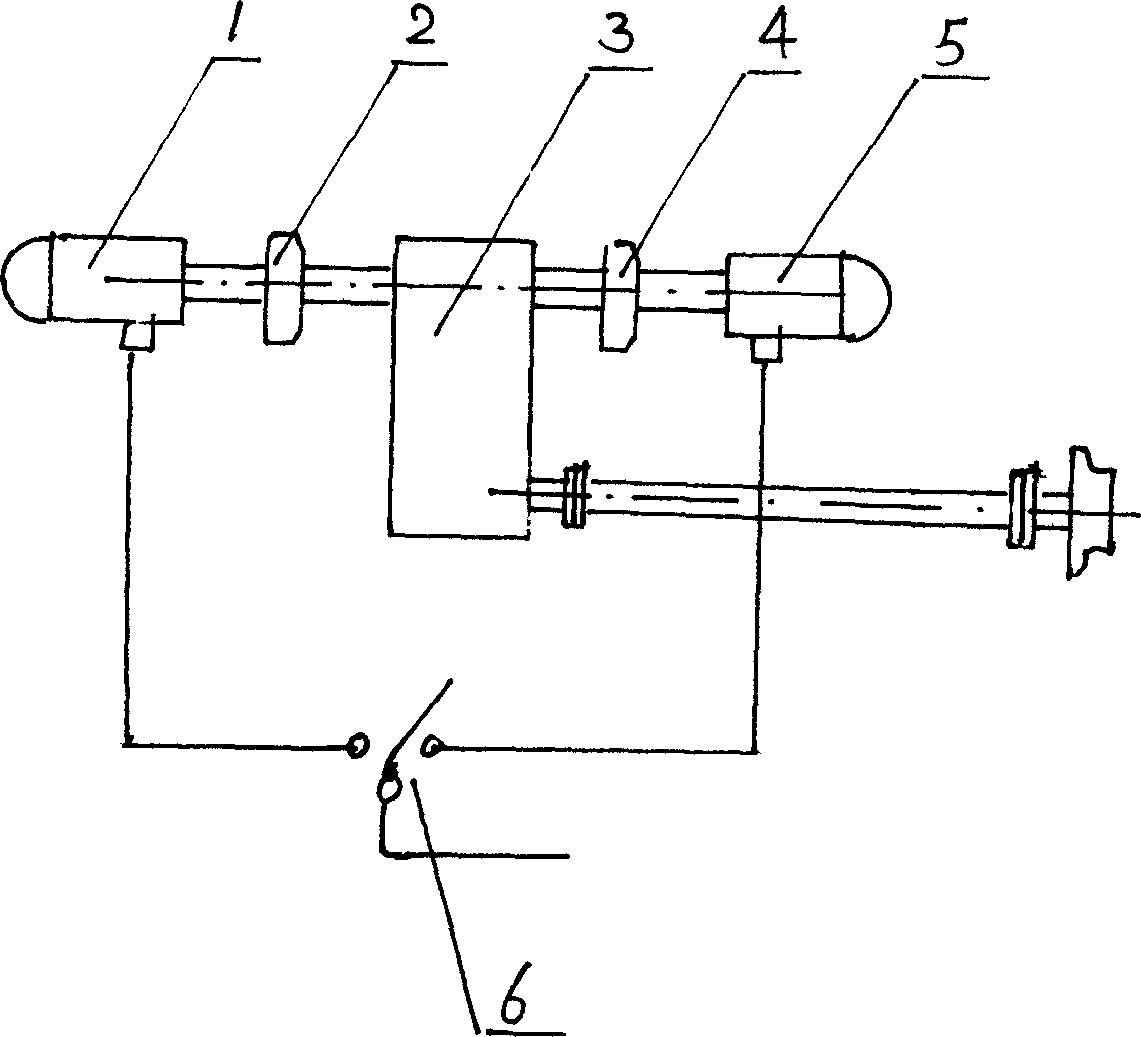

Tensioning tool for simultaneously manufacturing prestressed concrete pipe piles

The invention relates to a tensioning tool for simultaneously manufacturing a plurality of prestressed concrete pipe piles. The tensioning tool comprises a fixation plate (9) and a lock plate (3) arranged at two ends of a pipe pile mold (8). The lock plate (3) is provided with a tensioning screw (1), the screw (1) is provided with a locking nut (2) for locking the screw (1), one end of the screw (1) located in the pipe pile mold is provided with a tensioning plate (4) connected with the end plate of a cage of reinforcement, also included is a connection device located in the pipe pile mold (8) and between head and tail ends of two cages of reinforcement, the middle part of the connection device is provided with a through hole having a diameter the same as the inside diameter of the pipe pile, and the connection device is provided with a seal structure for preventing concrete from flowing into the connection device. The inventive tensioning tool is good to practice, that is, the tool can tension the cage of reinforcement, when a concrete pump and a pouring pipe are used for concrete pouring, without influencing pouring of the pouring pipe, and has good sealing performance.

Owner:宁波中淳高科股份有限公司

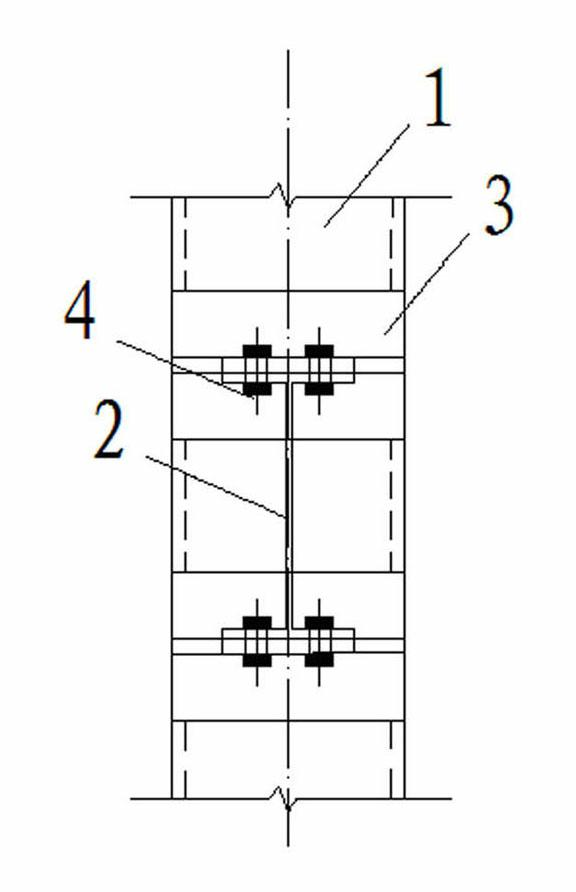

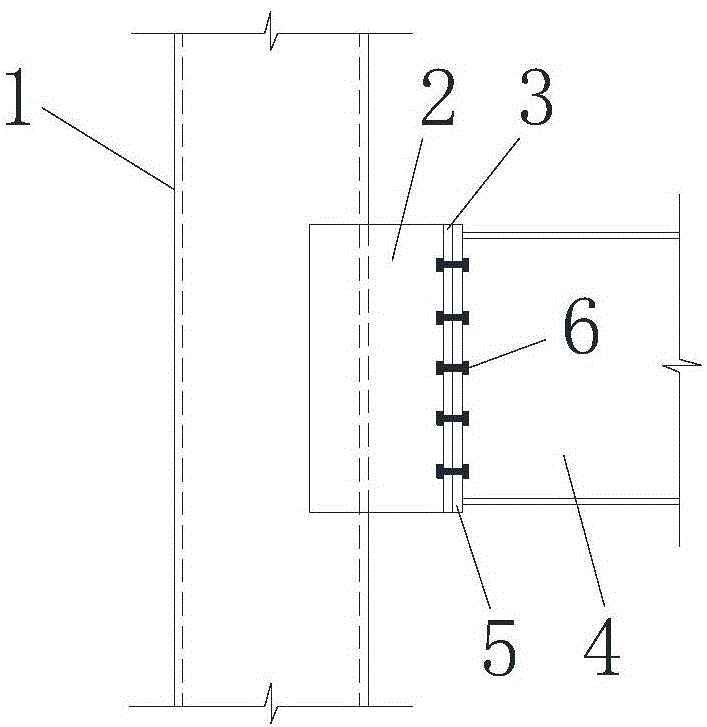

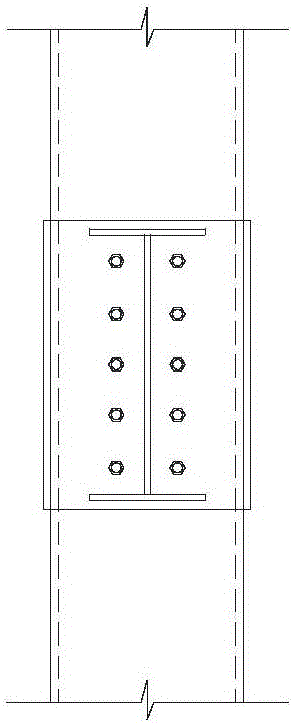

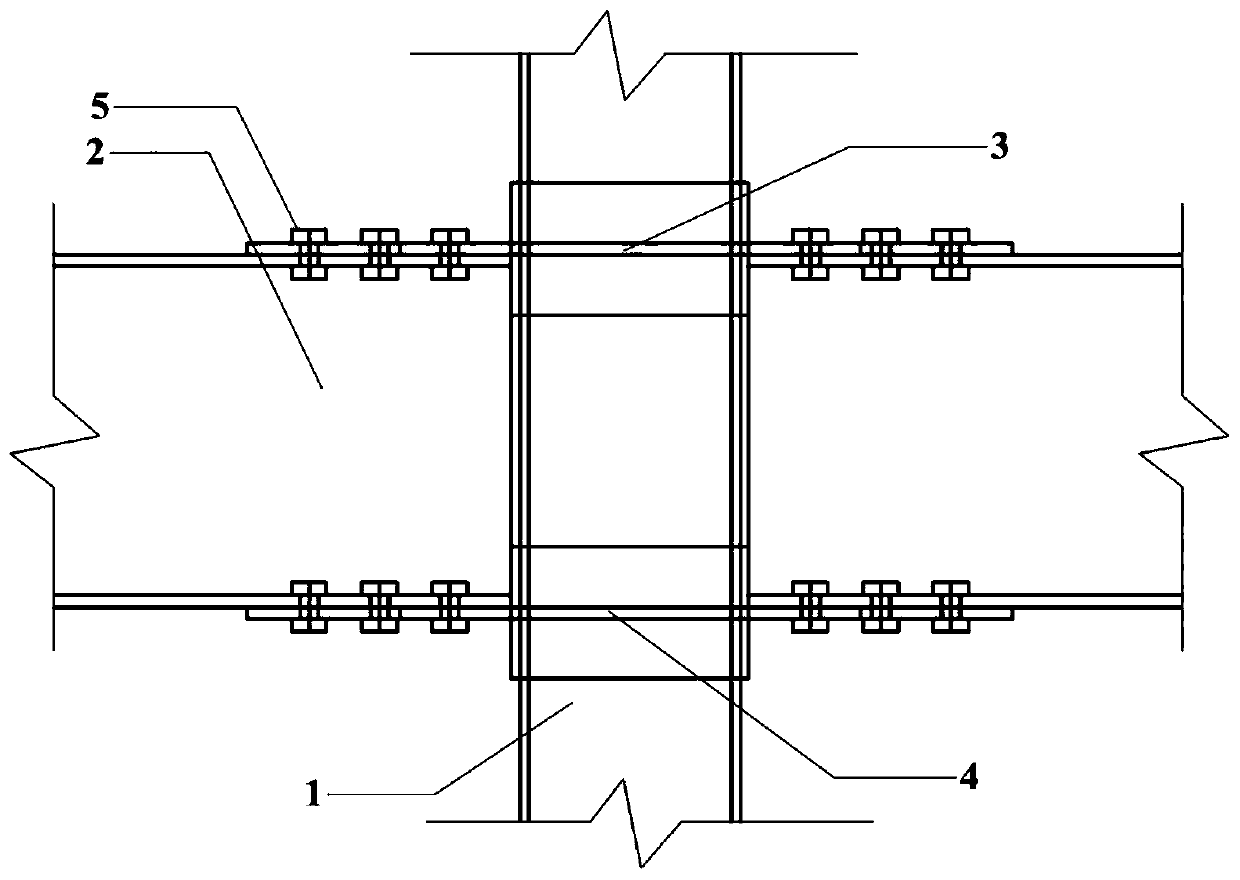

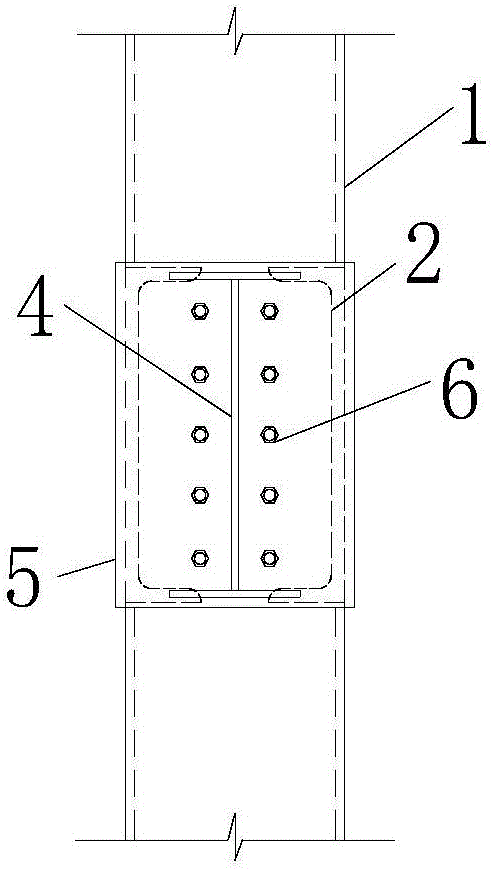

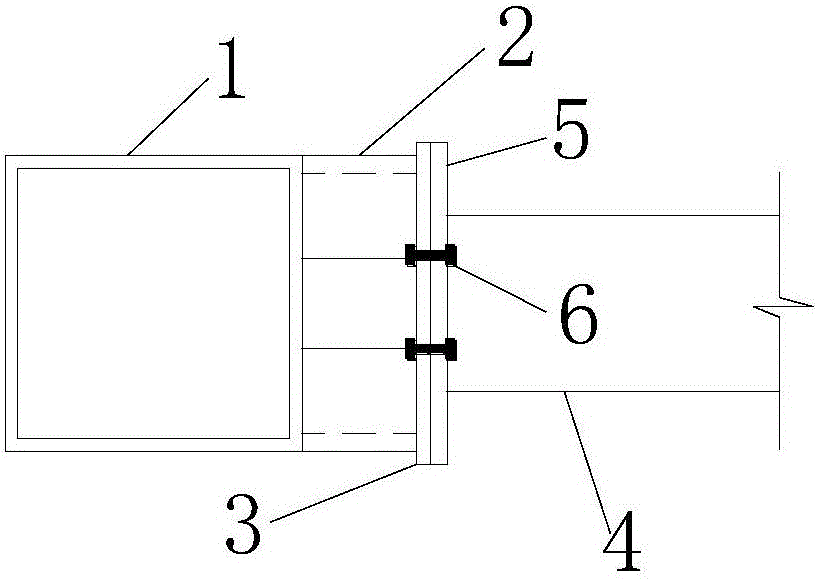

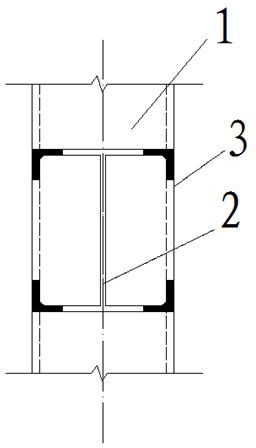

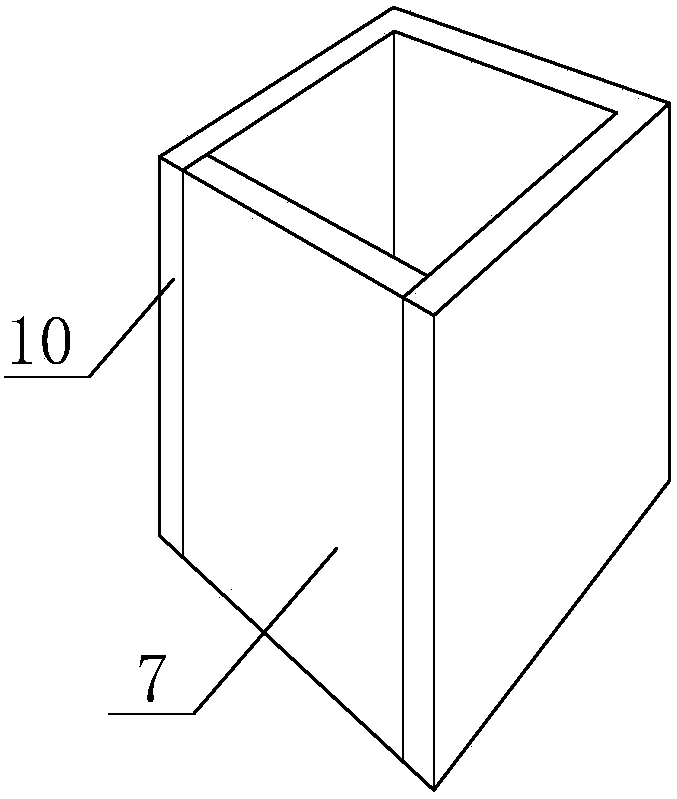

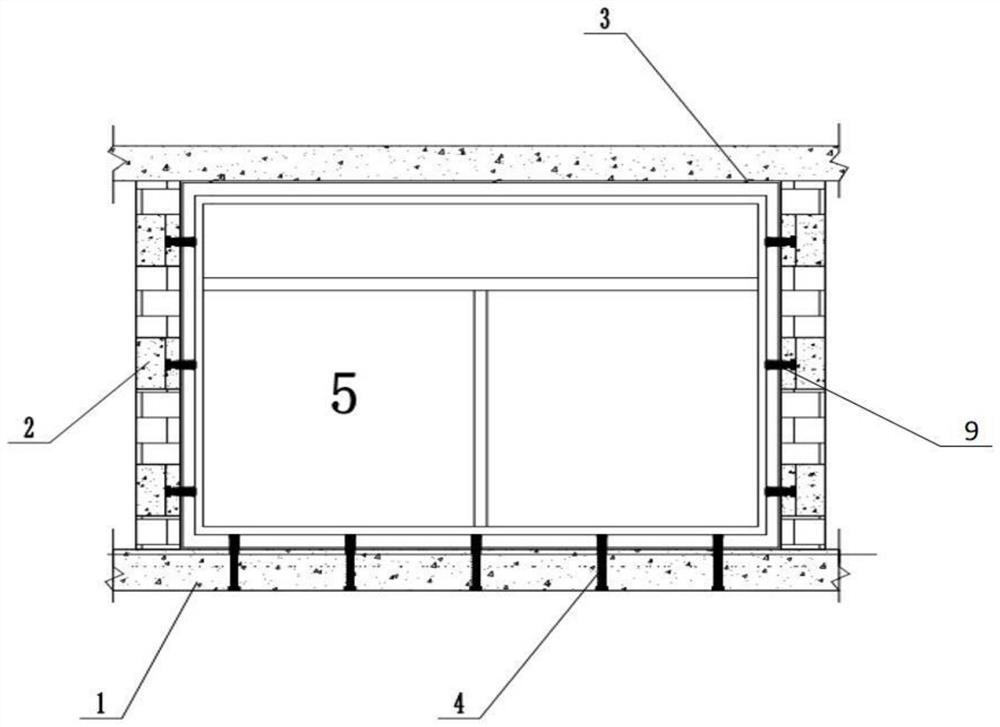

Square steel tube column-H-shaped steel beam end-plate connecting node

The invention discloses a square steel tube column-H-shaped steel beam end-plate connecting node which comprises a square steel tube column, an H-shaped steel beam, a node end plate, a beam end plate and side steel plates; the beam end plate is in weld connection with the end part of the H-shaped steel beam, and a bolt hole is formed in the beam end plate; the two side steel plates are in weld connection with wall plates on the two sides of the square steel tube column; the node end plate is in weld connection with each of the two side steel plates, and a screw hole corresponding to the beam end plate is formed in the node end plate; the square steel tube column and the H-shaped steel beam are connected into a whole through friction type high-strength bolts by means of the node end plate and the beam end plate. The square steel tube column-H-shaped steel beam end-plate connecting node disclosed by the invention is simple in structure and solves the construction problem caused as a partition plate is welded in the square steel tube, and meanwhile, the pouring of concrete in the steel tube is not affected; an anti-seismic design principle of 'strong node and weak component' is easy to realize, and the anti-seismic property is better; the construction efficiency is higher, and the suitability for the construction of the square steel tube column-steel beam connecting node in a multi-rise or high-rise building steel structure is realized.

Owner:YANSHAN UNIV

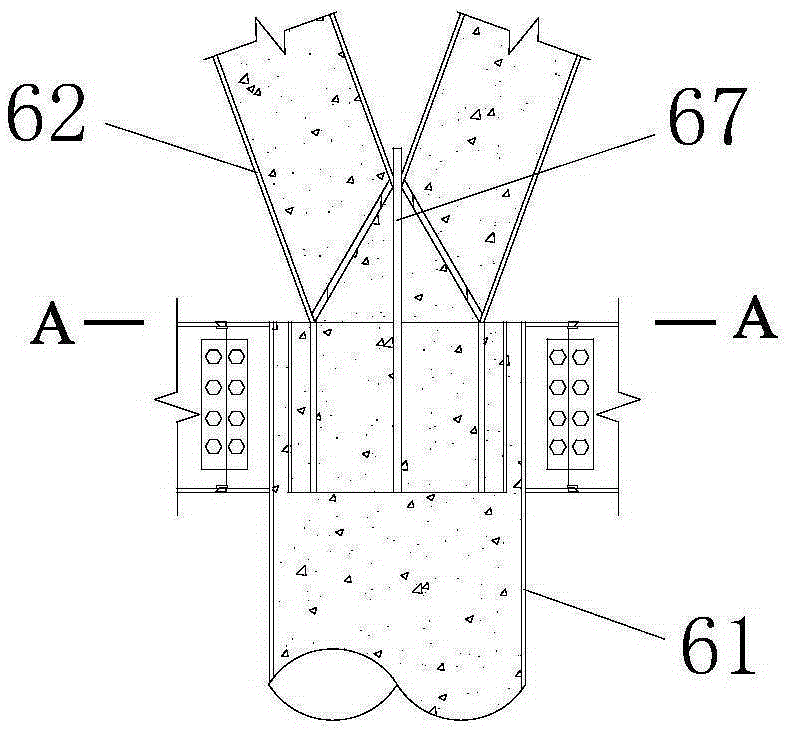

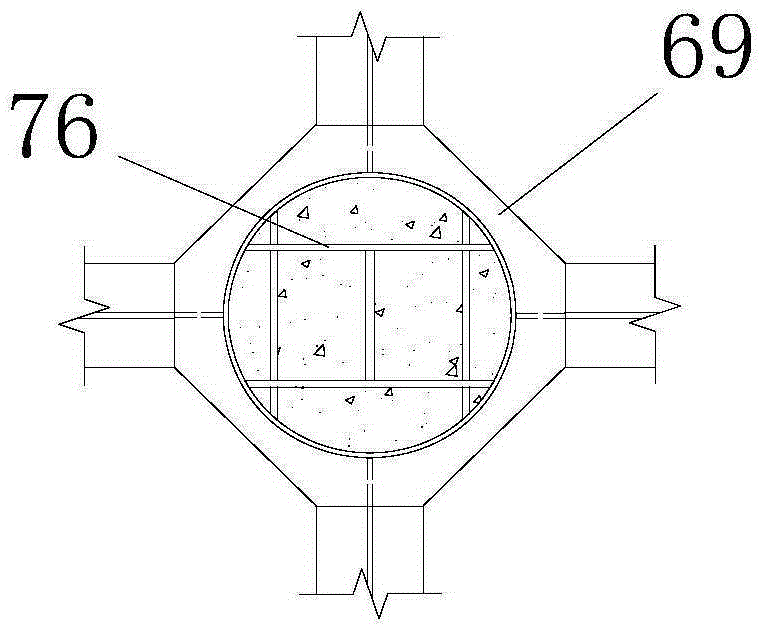

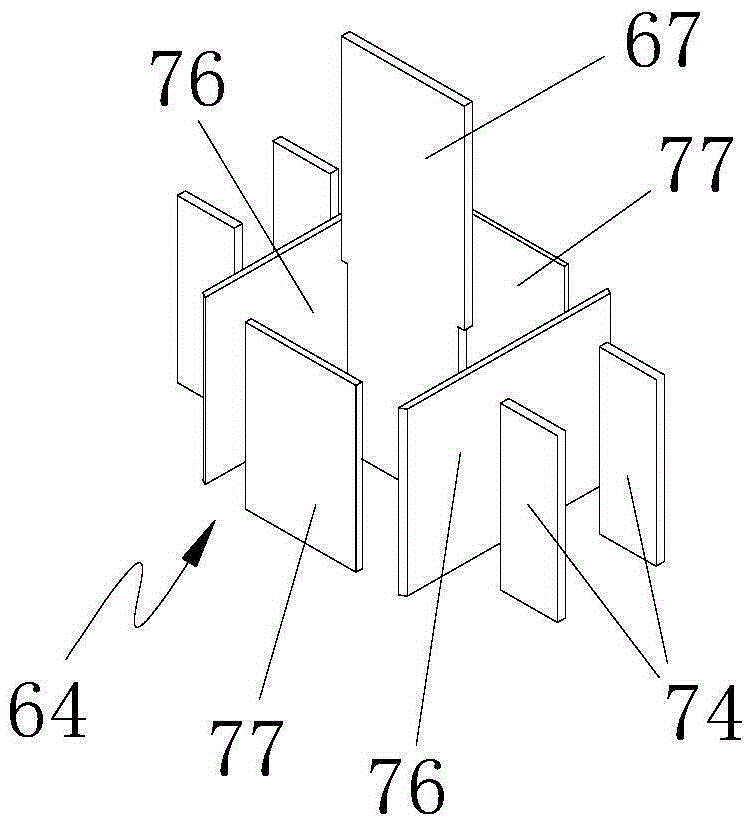

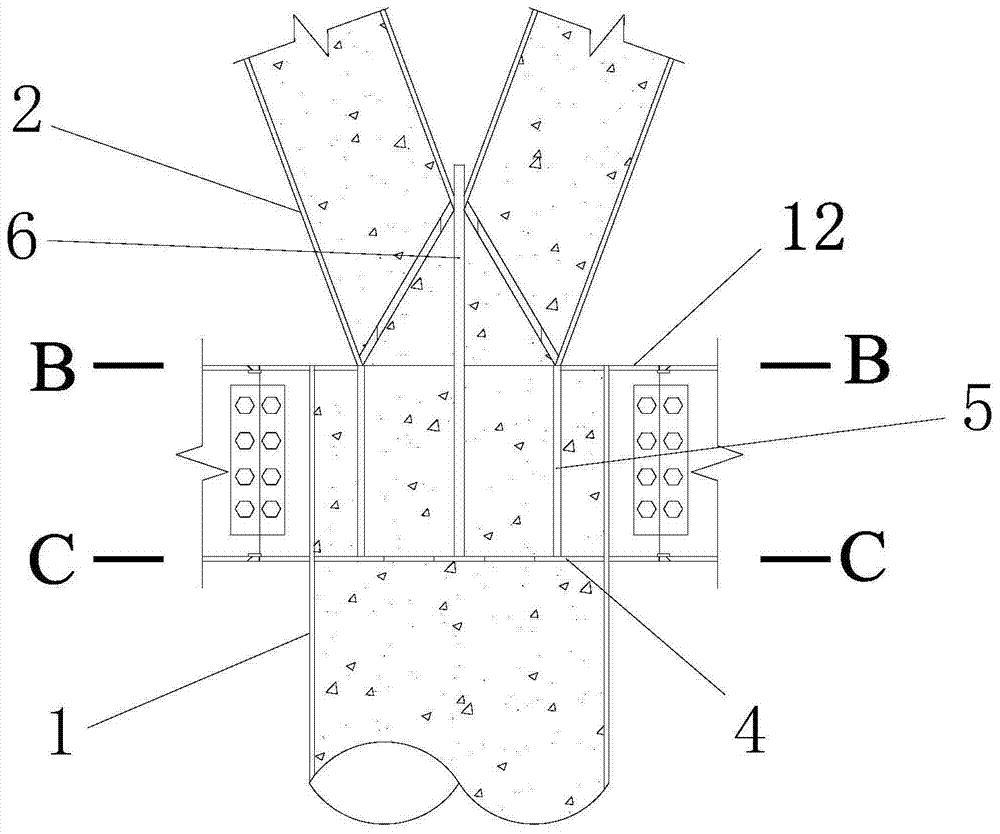

Concrete filled steel tube transfer joint structure and construction method thereof

The invention discloses a concrete filled steel tube transfer joint structure and a construction method thereof. The concrete filled steel tube transfer joint structure comprises a strut, a batter post and a socket frame; the batter post is fixedly connected to the socket frame; the socket frame is fixedly arranged inside the strut and located at a top end of the strut; the socket frame comprises a vertical inner ribbed plate; the batter post is provided with a section including a cross section; a shape of the vertical rib ribbed plate corresponds to a shape of the cross section and a connecting ribbed plate extends out of the vertical inner ribbed plate; the connecting ribbed plate extending out is fixedly connected to an inner wall of the strut; the batter post is fixed on the vertical inner ribbed plate through the section. The concrete filled steel tube transfer joint structure is integrated with the advantages of a concrete-filled steel tube and a battery post transfer structure, and has the advantages of direct force transfer, high bearing capacity, small sectional dimension of the component, good utilization of building space, no need for support formwork, small field welding workload, guaranteed construction quality and the like. Two batter posts and a beam system form a triangular force transfer mode, and meanwhile, excellent side force resisting capability is realized.

Owner:SOUTH CHINA UNIV OF TECH

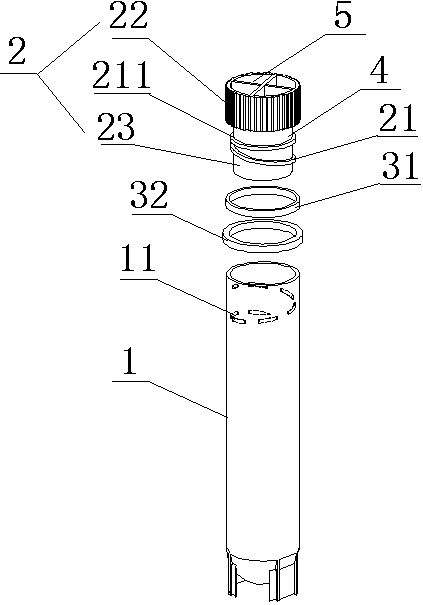

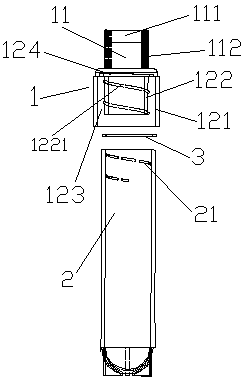

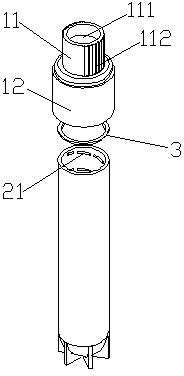

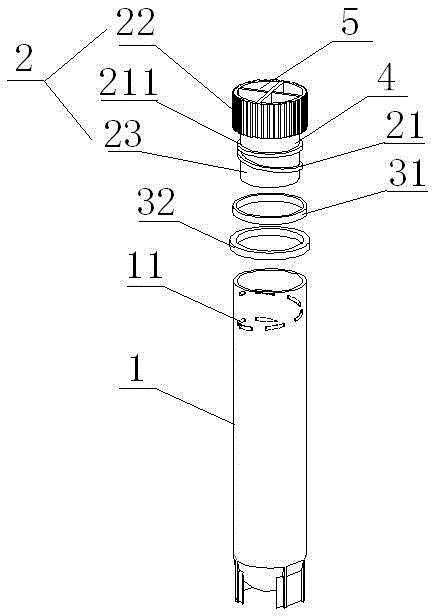

Improved structure of cryopreserved tube

ActiveCN103918643ASolve the defects that are easy to fallImprove sealingDead animal preservationEngineeringUltimate tensile strength

The invention belongs to the field of medical instruments, and particularly relates to an improved structure of a cryopreserved tube. The improved structure comprises a tube body and a tube cap, wherein the tube cap is connected with the tube body in an inner rotating manner; the tube cap is provided with an external thread; a tube opening of the tube body is provided with an internal thread; the internal thread is an internal thread section or an internal thread point provided with a notch therebetween. The cryopreserved tube provided by the invention is good in sealing effect, does not influence the pouring of substances inside the tube, is easy to screw, high in strength, has a mark classification function, saves the material, and is low in manufacturing cost.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

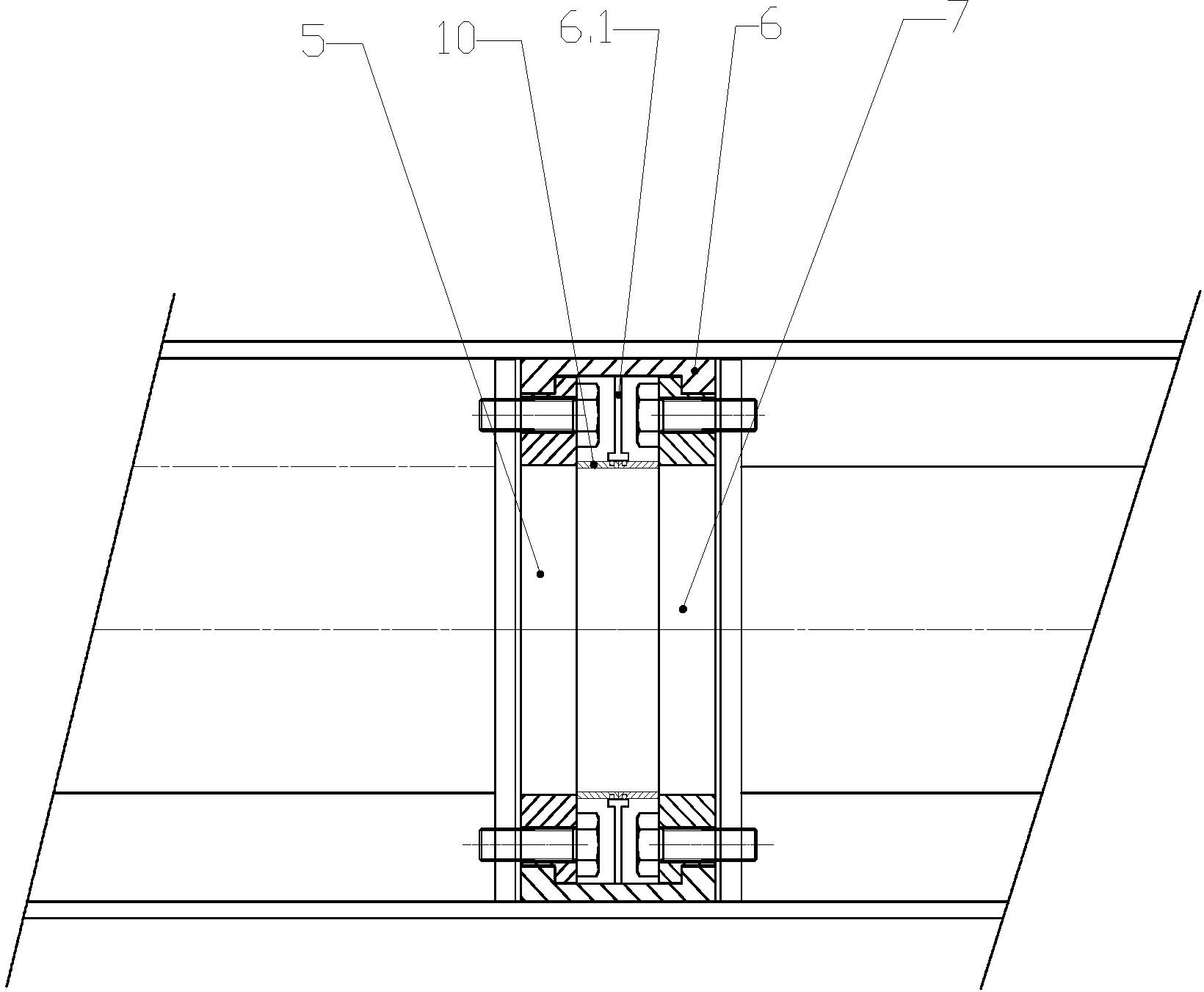

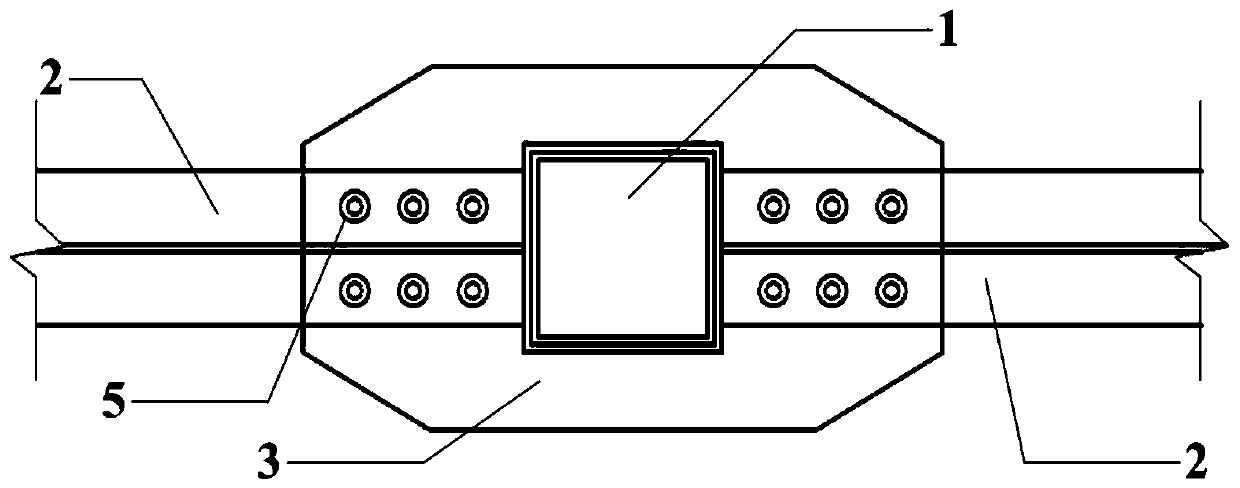

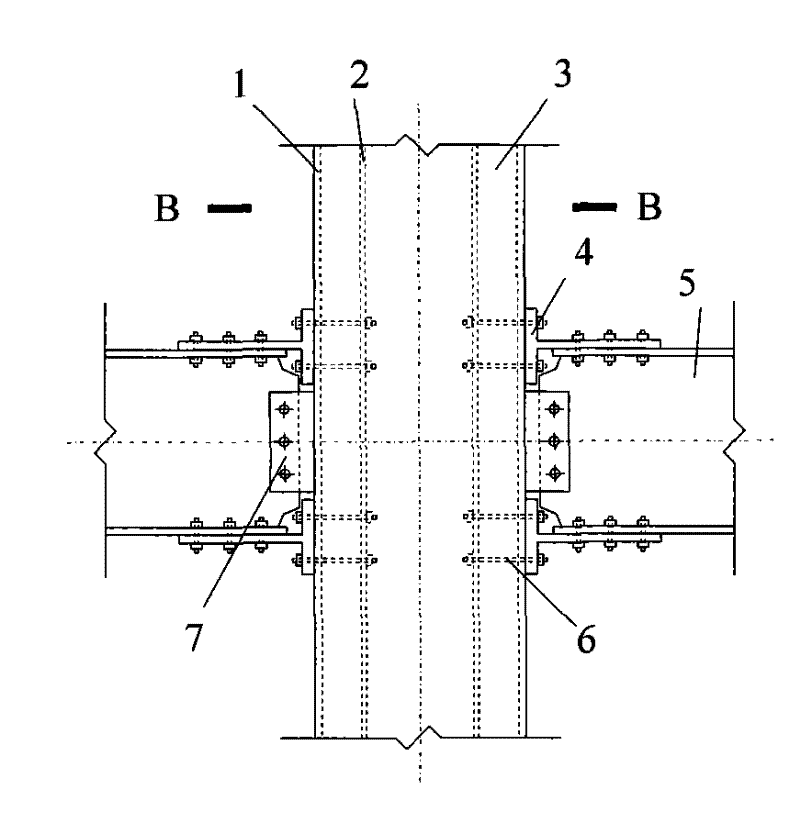

Square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint

InactiveCN111456235AIncrease the direct contact areaImprove distributionBuilding constructionsBoard structureSteel tube

The invention discloses a square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint. The square steel tube concrete column-steel beam outer ring sleeve plate bolt connection joint comprises a square steel tube, the square steel tube is sleeved with an upper outer ring sleeve plate and a lower outer ring sleeve plate, the upper outer ring sleeve plate comprises an upper short sleeve, an inner surface of the upper short sleeve is connected with the square steel tube, an outer surface of the upper short sleeve is connected with an upper outer ring plate, the lowerouter ring sleeve plate and the upper outer ring sleeve plate are of the same structure, the lower outer ring sleeve plate comprises a lower short sleeve and a lower outer ring plate, and a steel beam is connected between the upper outer ring sleeve plate and the lower outer ring sleeve plate. The distribution of a column wall yield line is expanded, the column wall rigidity of a joint domain isimproved, and the contribution of an outer ring plate to the joint bearing capacity under the action of external load is increased; the defect that the rigidity at the joint is insufficient due to thefact that an inner ring plate is not arranged is overcome; by adopting the method, the field operation amount is small, the steel structure construction efficiency is improved, the material utilization rate is increased, and good economic benefits and social benefits are achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

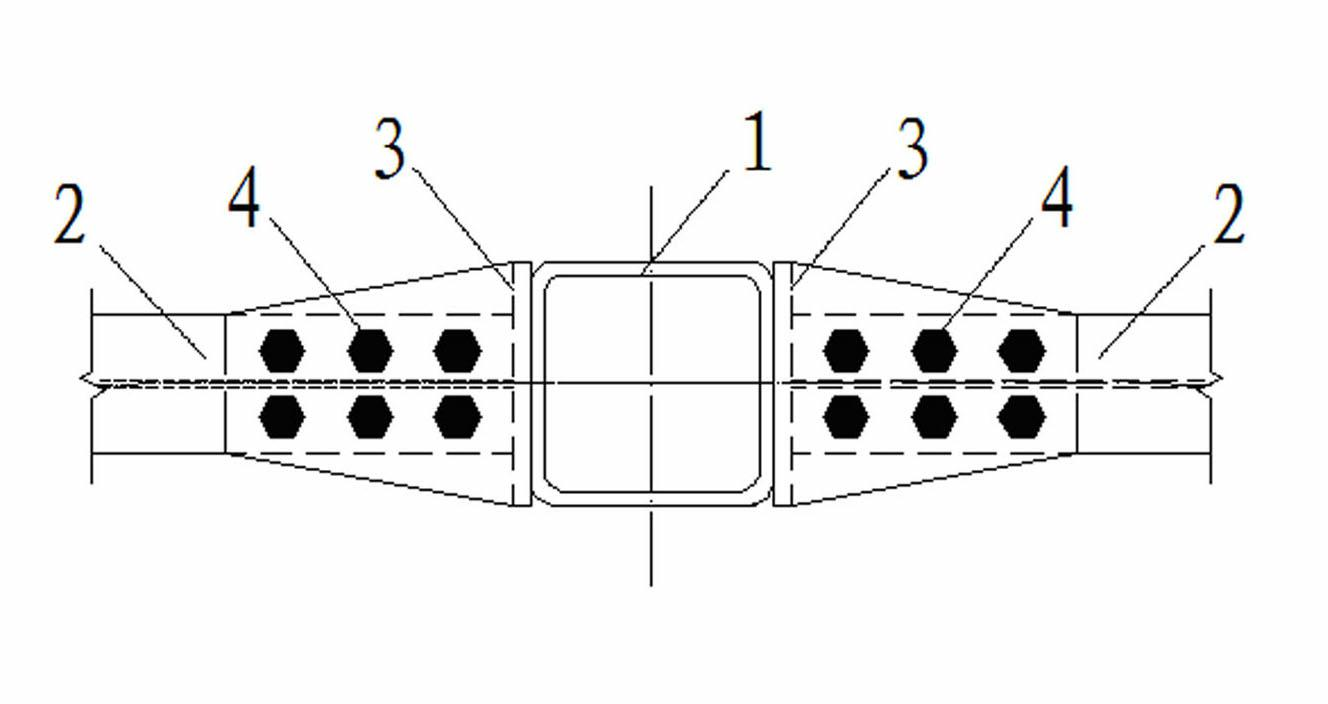

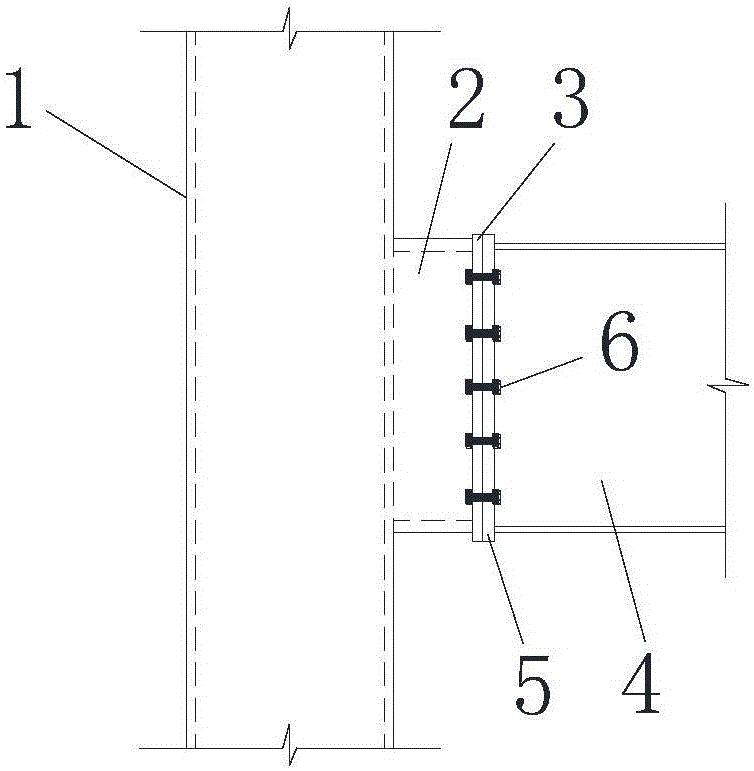

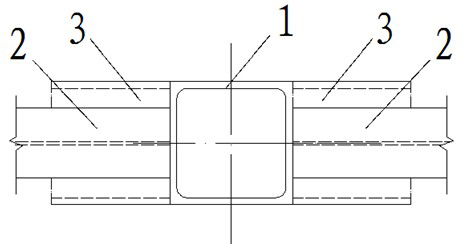

Channel steel end plate joint for square steel string

InactiveCN106703193AAvoid settingEasy to manufactureBuilding constructionsSocial benefitsArchitectural engineering

A channel steel end plate joint for a square steel string is mainly characterized in that one ends of two equal-length channel steel segments with opposite openings are perpendicularly fixed to a flange of the square steel string, a joint end plate covering the two channel steel segments is fixed to the other ends, the top ends of the channel steel segments placed vertically or horizontally are positioned in the flange of the square steel string, the joint end plate is provided with a plurality of bolt holes, a beam end plate covering an end of an I-beam is additionally fixed to the end of the I-beam to be connected to the square steel string, the beam end plate is provided with bolt holes corresponding to the joint end plate, and the corresponding bolt holes in one pair in the beam end plate and the joint end plate are each provided with a high-strength bolt inside for fixing the two plates together. The channel steel end plate joint is simple in structure, the construction problem due to the welding of a partition in a square steel tube is solved, and the casting of concrete in the square steel tube is unaffected; the anti-seismic design rules of 'strong joints and weak members'are easy to implement, and the anti-seismic performance is good; the channel steel end plate joint has high construction efficiency and great economic and social benefits.

Owner:YANSHAN UNIV

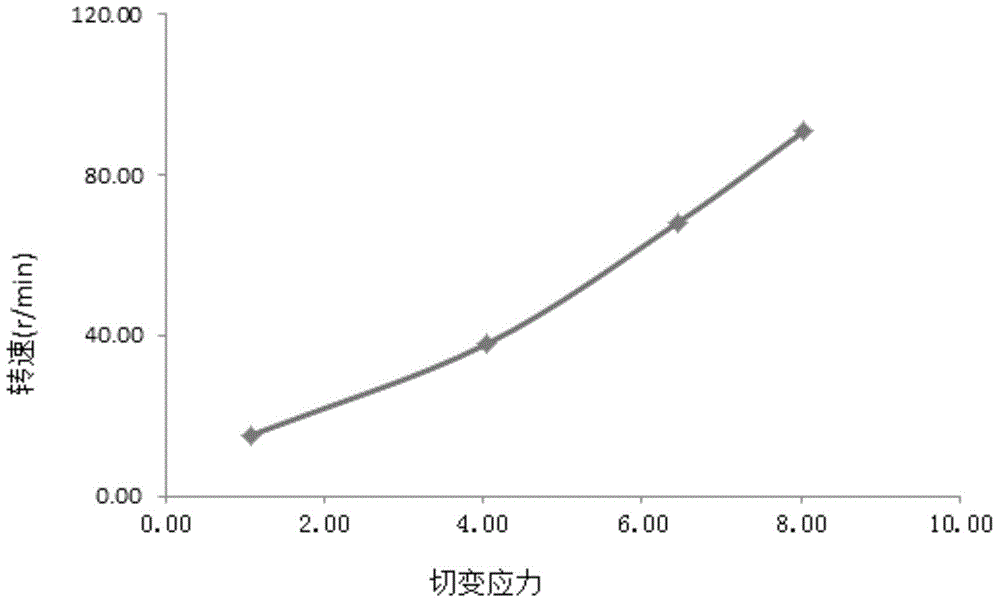

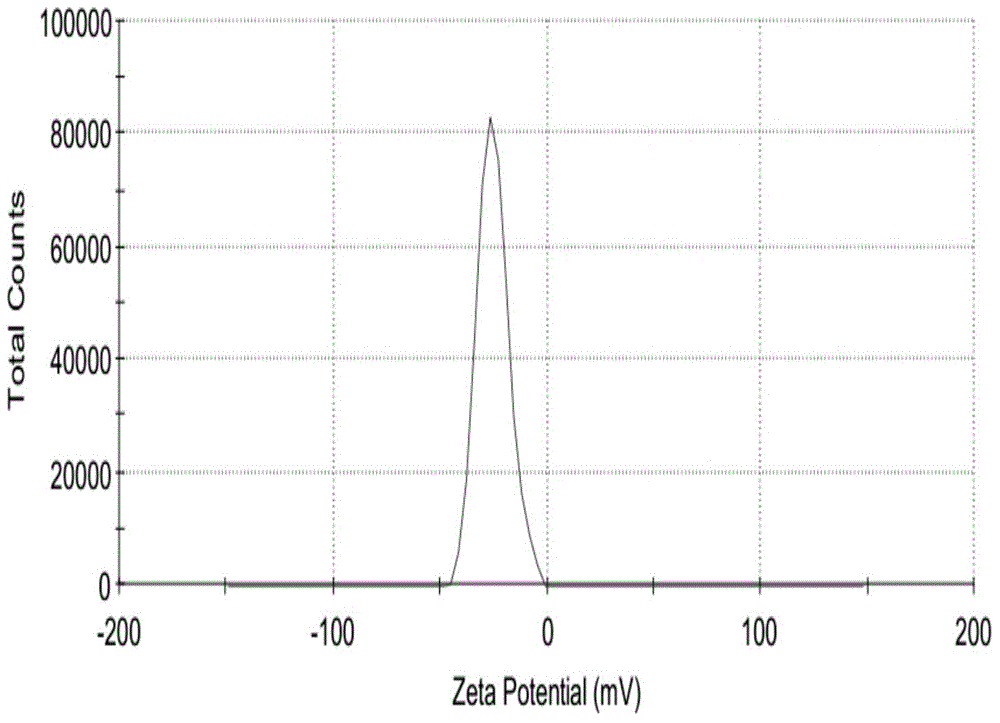

Traditional Chinese medicine dry suspension and preparation method thereof

InactiveCN104644993AAvoid bitterness and other bad tasteIncrease viscosityPowder deliveryPharmaceutical non-active ingredientsDrug contentBitter taste

The invention discloses a traditional Chinese medicine dry suspension and a preparation method thereof, belonging to the field of pharmaceutical preparation. The traditional Chinese medicine dry suspension consists of bitter taste masking traditional Chinese medicine powder, xanthan gum, RC-A591NF. According to the invention, bitter taste masking treatment is performed on traditional Chinese medicine extract, the sedimentation ratio of the finally obtained traditional Chinese medicine dry suspension can reach 0.9-1.0, the medicine content uniformity is good, rheological property research shows that the traditional Chinese medicine dry suspension is pseudoplastic fluid, according to a taste evaluation test, the dry suspension has no bad taste, the palatability is good, and the dry suspension can be accepted by a patient easily.

Owner:TIANJIN UNIV OF TRADITIONAL CHINESE MEDICINE

Connecting node of square steel pipe column, H-shaped steel beam and L-shaped ribbed plate

InactiveCN102359192AAdd out-of-plane deformationSimple structureBuilding constructionsSheet steelButt joint

The invention relates to a connecting node of a square steel pipe column, an H-shaped steel beam and an L-shaped ribbed plate. The node is simple in structure, convenient to construct and is free of affecting to pour concrete in the square steel pipe column. The connecting node comprises the square steel pipe column, the H-shaped steel beam and the L-shaped ribbed plate, wherein two limbs of the L-shaped ribbed plate are respectively in butted joint with the upper flange and the lower flange of the H-shaped steel beam and connected with a wall plate of the square steel pipe column. The width B of the flange of the H-shaped steel beam 1 is twice the sum of the lengths b1 of the limbs of the L-shaped ribbed plate in butted joint with the H-shaped steel beam 1. The square steel pipe column comprises a cold bending rectangular square steel pipe column and a hot rolled square column; and the H-shaped steel beam comprises an H-shaped hot rolled steel beam and an H-shaped welded steel beam. The connecting node of the square steel pipe column, the H-shaped steel beam and the L-shaped ribbed plate in the invention adopts a measure of additionally arranging stiffening ribs outside to replace inner partition plates, and the L-shaped ribbed plate can transfer tension and pressure of the flanges of the beam to the wall of the square steel pipe column, so that the deformation outside a plane of the node is increased. Meanwhile, the problem of construction difficulty in installing the inner partition plates can also be avoided.

Owner:SHENYANG JIANZHU UNIVERSITY

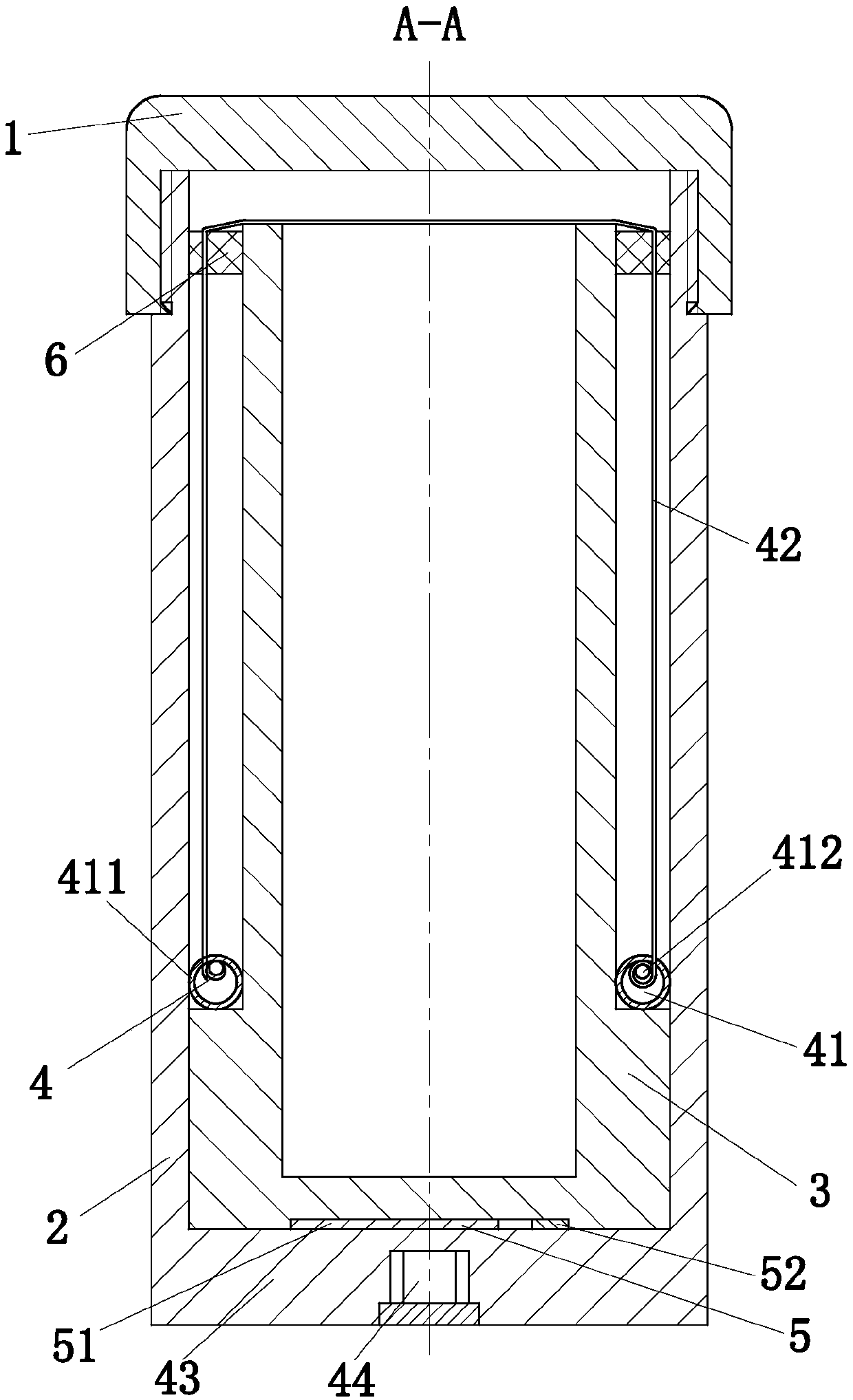

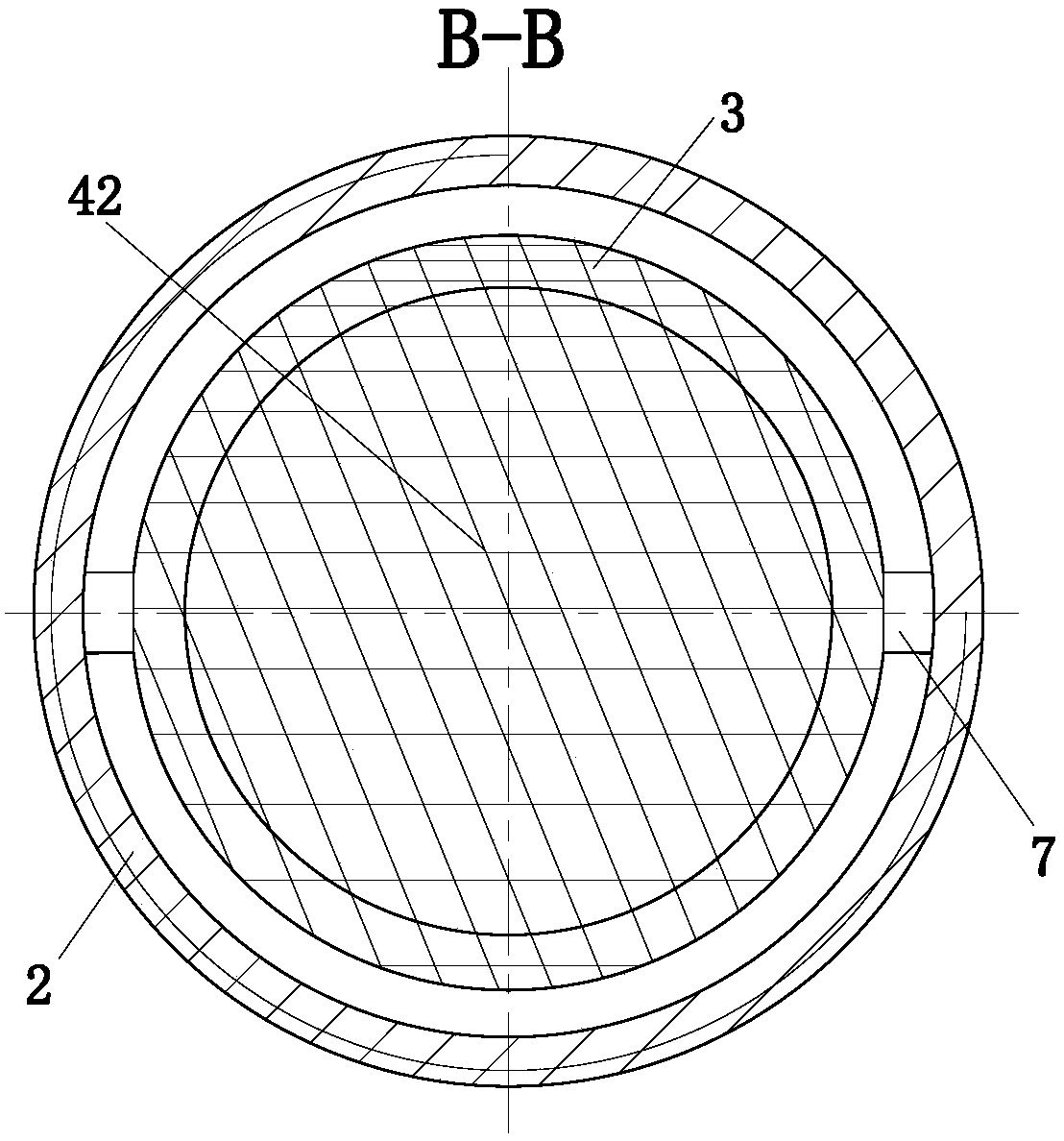

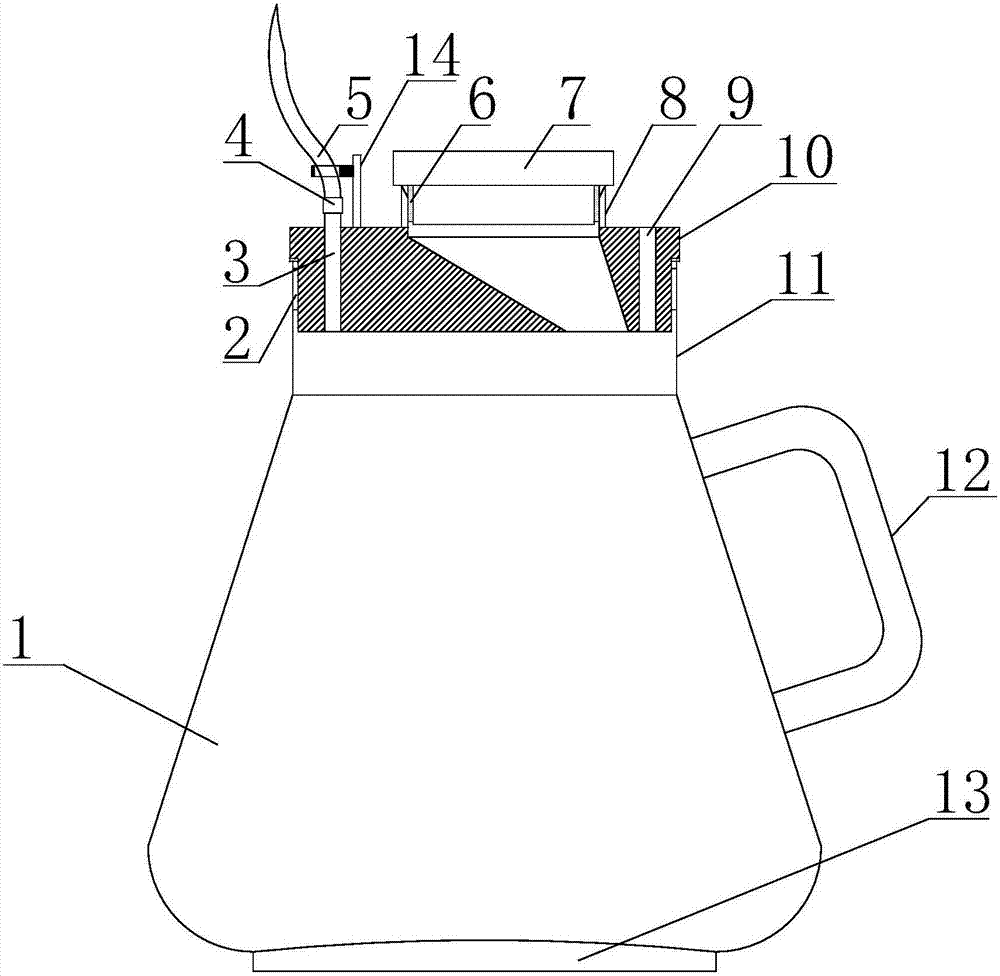

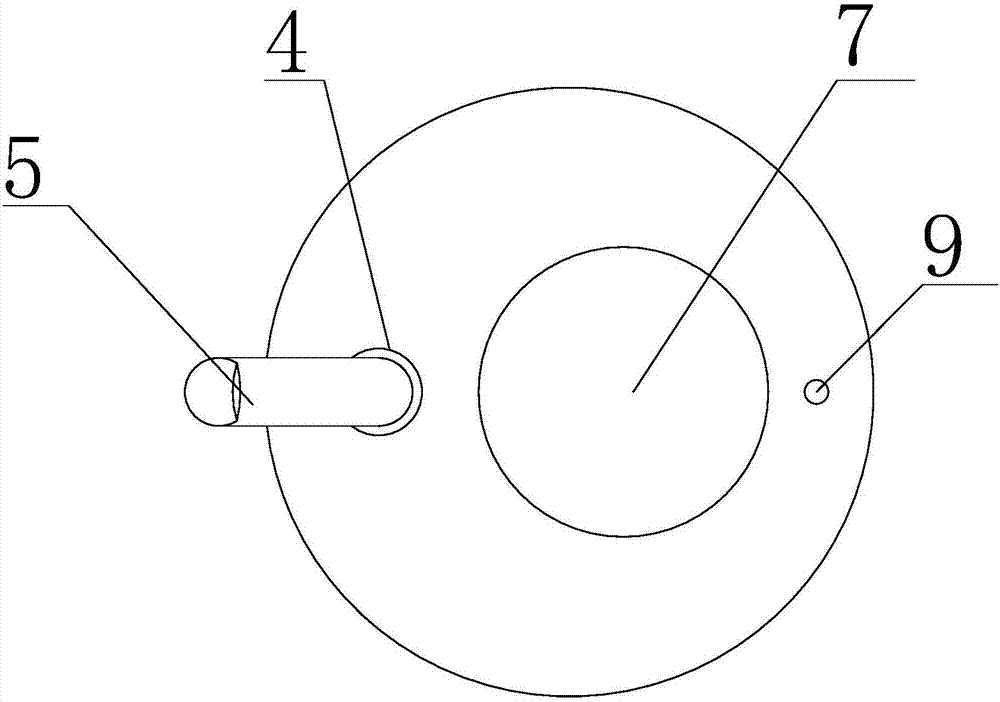

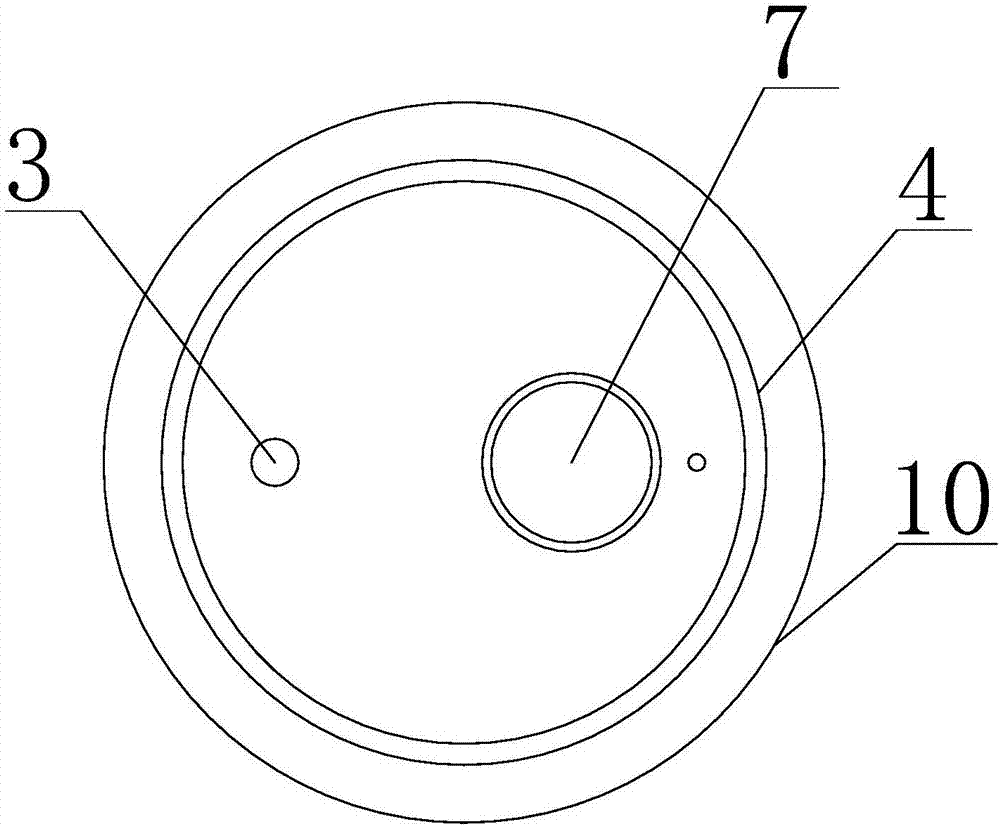

Cup with screen net arranged internally

InactiveCN107853955ADoes not affect pouringGuaranteed continuous useBeverage vesselsDrinking vesselsWaste managementWater flow

The invention belongs to the field of articles of daily use, and particularly relates to a cup with screen net arranged internally. The cup comprises a cup cover, a cup body, a liner, a filtering module, a heating module, a seal ring, a partition plate and a switch button, wherein the cup cover is screwed on the cup body through threads, the upper end of the cup body is opened, a charging interface is formed in the bottom of the cup body, and the switch button is arranged on the outer wall of the cup body and used for controlling work of the filtering module; the liner is a cylinder and is ininterference fit with the cup body; the filtering module is arranged in a cavity between the liner and the cup body and used for changing the mesh density of a filtering net above the liner and reducing retardation to water by the filtering net; the heating module is used for heating water in the cup, the seal ring is used for preventing fluid from flowing into the cavity, and the partition plateis located in the cavity and used for dividing the cavity into two parts. Water flow is capable of passing the filtering net fast without being blocked in the process of adding water into the cup, andtherefore the water adding process is fast and safe.

Owner:吴国秋

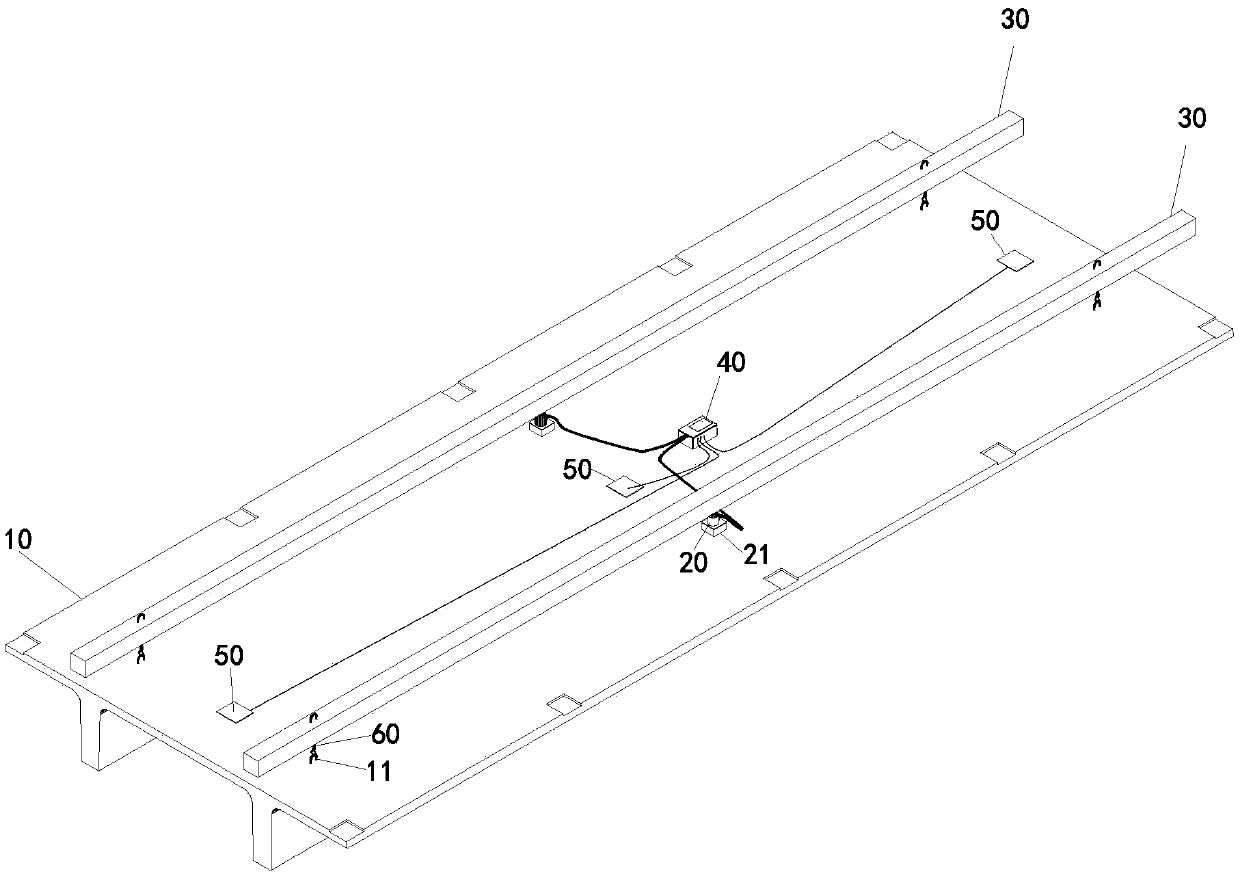

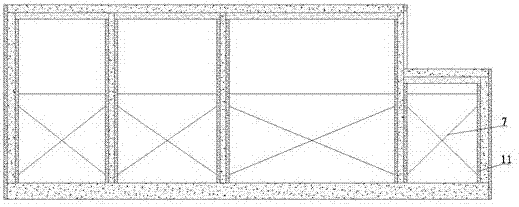

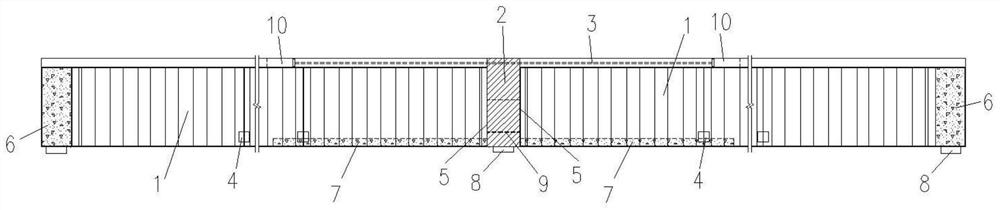

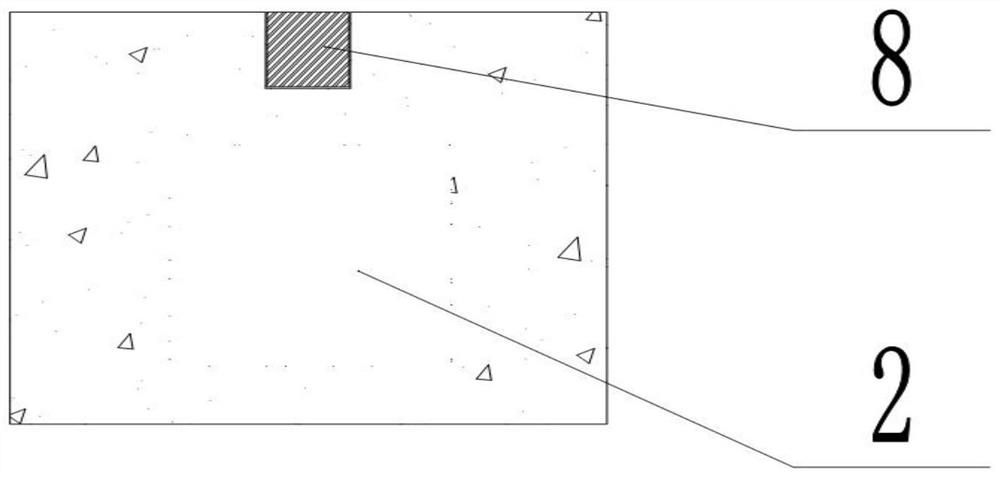

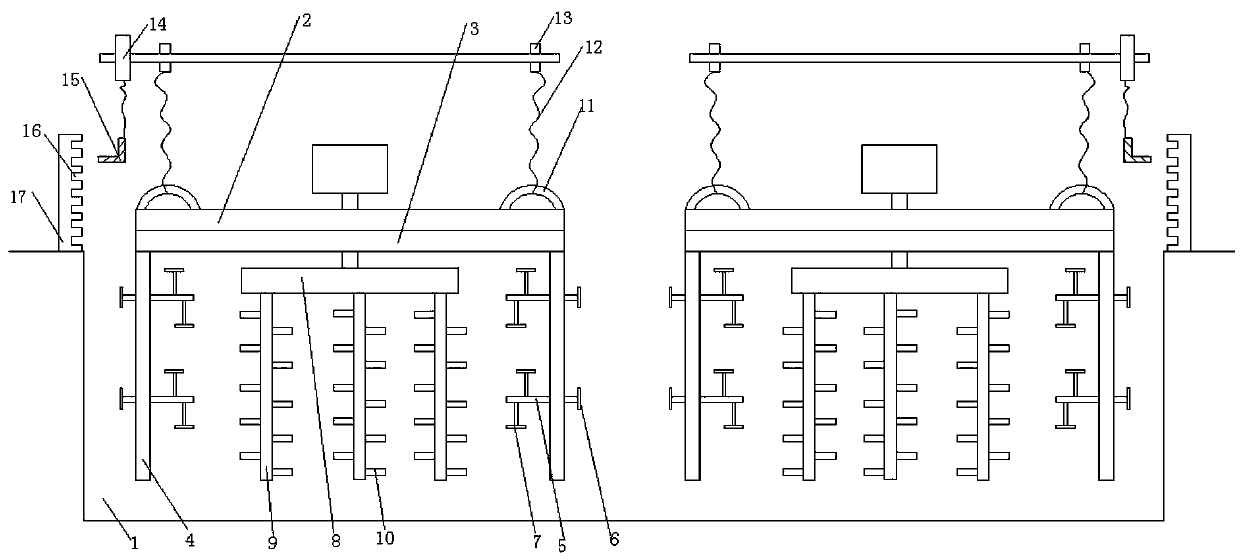

Assembled prestressed large plate inverted-camber self-adjusting system and using method thereof

PendingCN109537787AReduce stepsHigh degree of automationFloorsBuilding material handlingAutomatic controlCamber angle

The invention discloses an assembled prestressed large plate inverted-camber self-adjusting system and a using method thereof. The inverted-camber self-adjusting system comprises a hydraulic loading device, counter force frames, an adjusting control reactor and a plurality of inverted-camber measuring pieces; the counter force frames are distributed in the length direction of a prestressed plate,and the two ends of each counter force frame are connected with hanging points of the end portions of the prestressed plate through flexible connecting pieces; the hydraulic loading device is arrangedat the lower portions of the middles of the counter force frames; the inverted-camber measuring pieces are used for measuring the inverted-camber value of the prestressed plate; the adjusting controlreactor is used for collecting measuring data of the inverted-camber measuring pieces, analyzing whether or not the inverted-camber value exceeds a set limit value and controlling the hydraulic loading device to be turned on and turned off. The inverted-camber self-adjusting system can achieve automatic control over the inverted-camber adjustment of the assembled prestressed plate, ensure that the inverted camber of the assembled inverted-camber plate meets the specified requirement and reduce the operation of field workers, and has the advantages of being high in automation degree and construction speed, capable of achieving the good construction effect and reusable.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

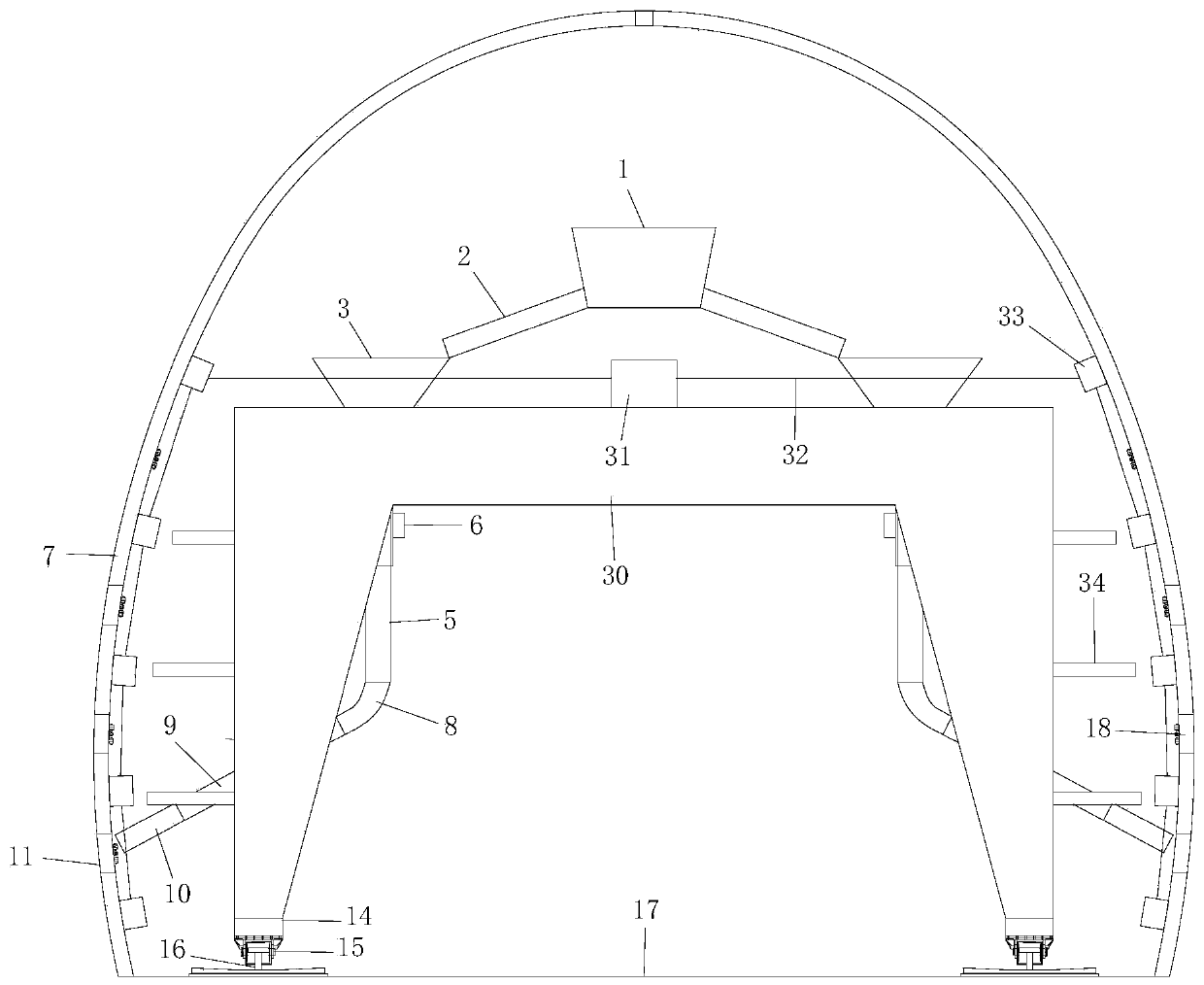

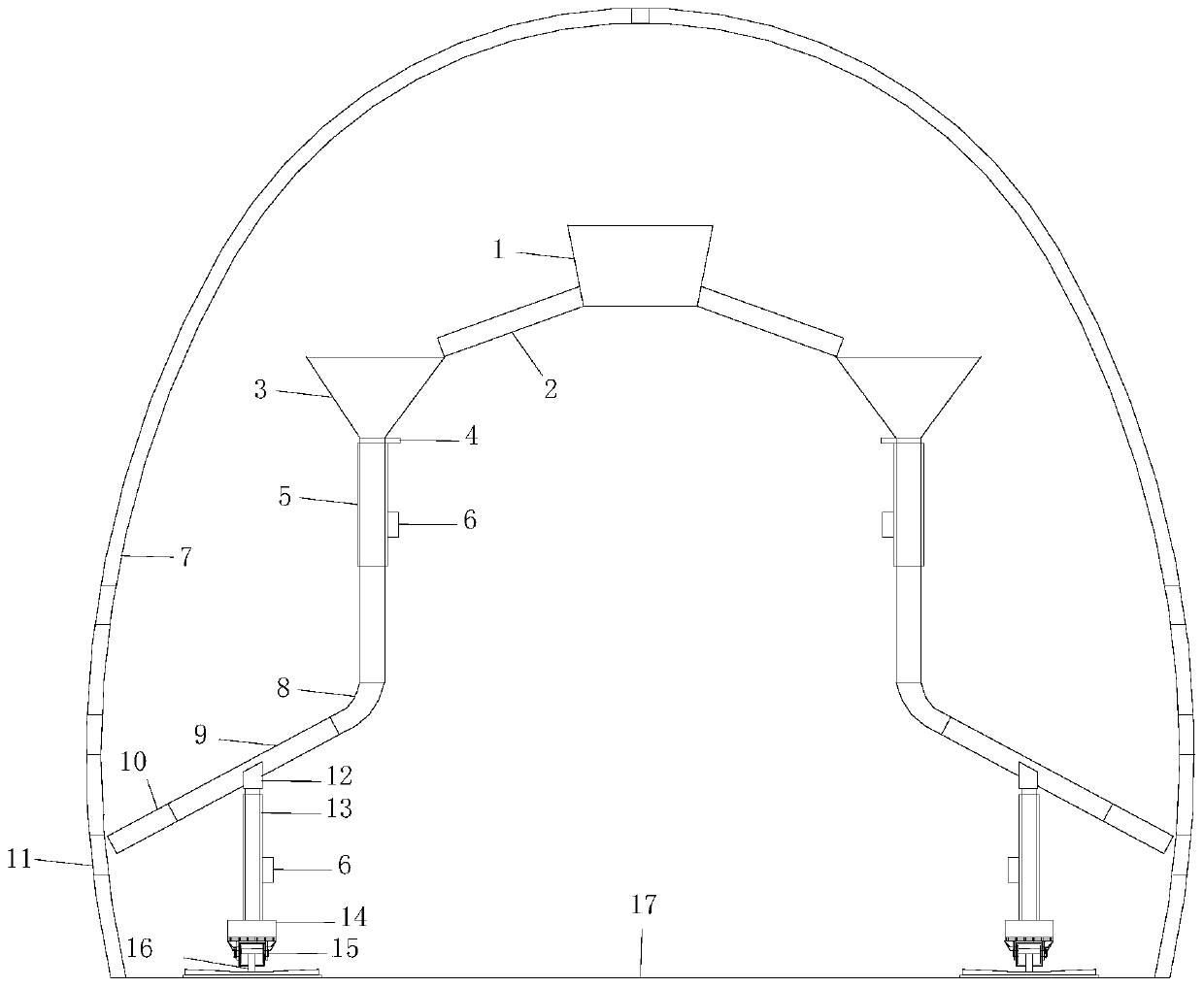

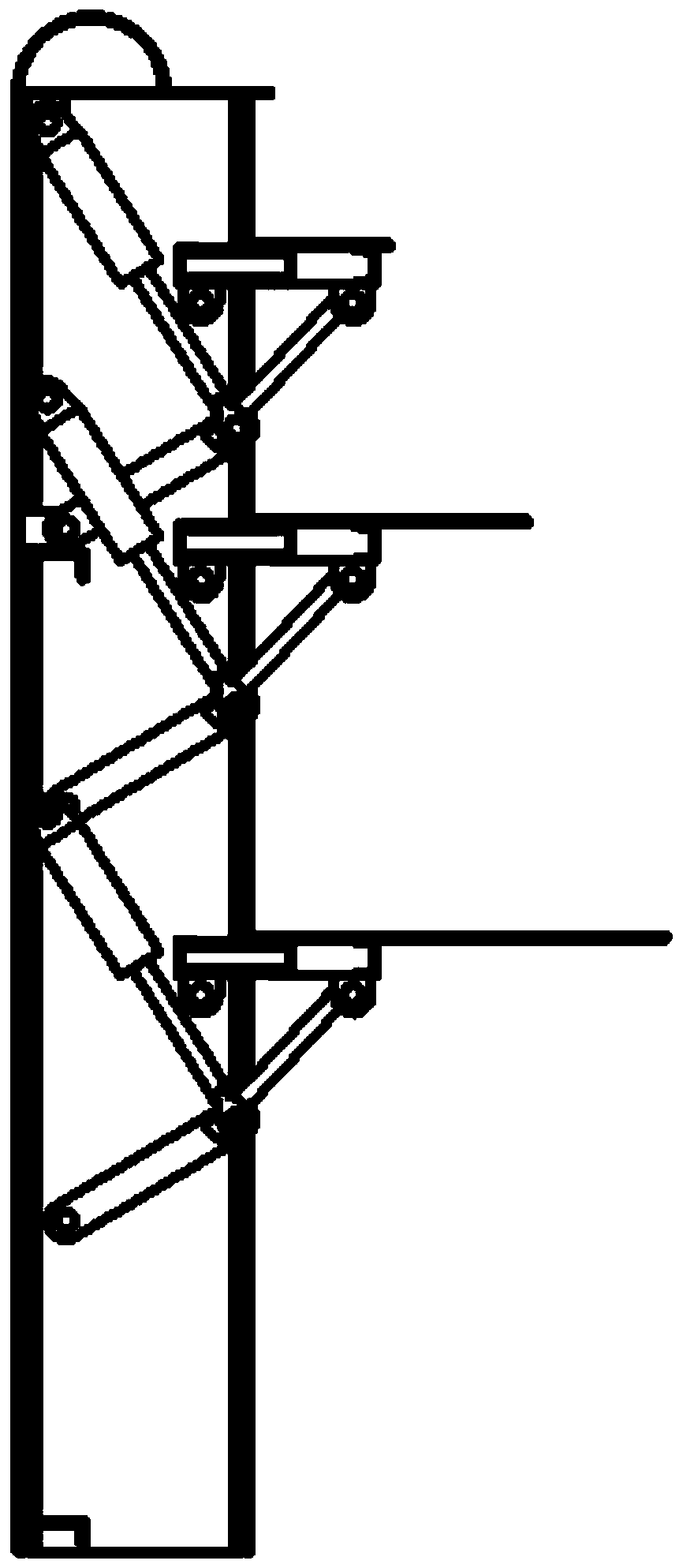

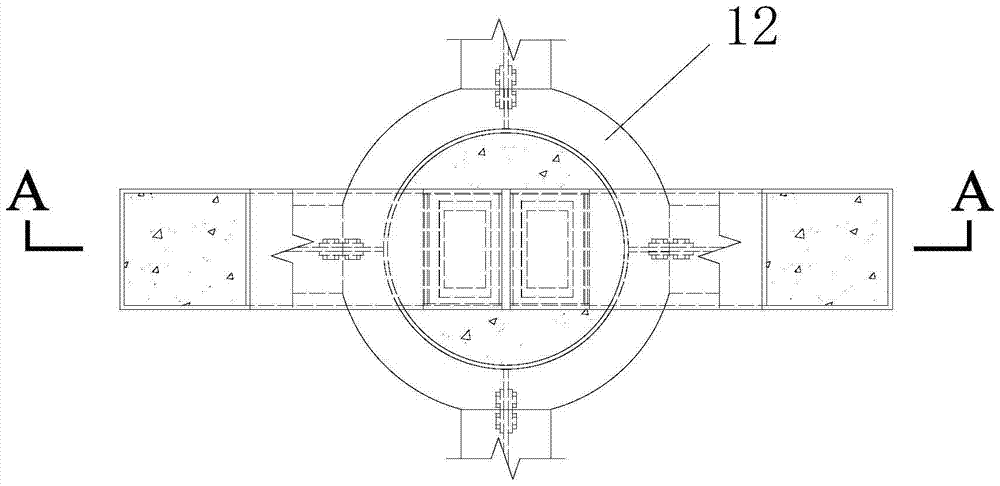

Tunnel second-lining concrete chute pouring system and construction method

ActiveCN110924988ARealize layer-by-layer and window-by-window mold entryQuality improvementUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention relates to a tunnel second-lining concrete chute pouring system. The tunnel second-lining concrete chute pouring system comprises a tunnel second-lining concrete chute system, a rapid closing structure of a lining formwork pouring window and a tunnel second-lining concrete multi-layer synchronous vibrating device. The tunnel second-lining concrete chute system comprises a main hopper, auxiliary hoppers, an inserting plate, a steel formwork, a fixed sling groove, a movable sliding groove, pouring windows, top supports, lifting supporting rods, a track and a tunnel pavement; the rapid closing structure of the lining formwork pouring window comprises the steel formwork, the pouring windows, hinged lug plates, closing plates, hinged bolt holes, fixed bolt holes and rubber sealingrings; and the tunnel second-lining concrete multi-layer synchronous vibrating device comprises the steel formwork, the pouring windows, bottom beams, trolley portals, a power distribution boxes, networking electric wires, attached flat vibrators, and extension platforms. The tunnel second-lining concrete chute pouring system has the beneficial effects that telescopic flow-dividing tumbling barrels and the lifting supporting rods are adopted, the heights of the sliding grooves can be flexibly adjusted to be suitable for pouring windows with different heights.

Owner:ZHEJIANG ZHENGFANG TRAFFIC CONSTR CO LTD

Waste-free edible oil bottle convenient for oil to pour out

The invention discloses a waste-free edible oil bottle convenient for oil to pour out. The edible oil bottle comprises a bottle body, an oil outlet pipe, an oil feeding hole, a bottle cap and a handle. An opening is formed in the top of the bottle body, the bottle cap is connected with the inner side of the opening in a sleeved mode, one side of the bottle cap is fixedly connected with the oil outlet pipe which penetrates through the bottle cap, the top end of the oil outlet pipe is fixedly connected with an oil pouring pipe through a connection ring, the oil feeding hole is formed in the position, on one side of the oil outlet pipe, of the bottle cap, the top of the oil feeding hole is sleeved with an oil feeding cap, and the handle is fixedly connected with one side of the bottle body. When the oil outlet pipe is fixedly connected with the oil pouring pipe through the connection ring, the length for draining the oil is increased; a pipe mouth of the oil outlet pipe is slant, so that straight oil leakage is avoided; the portion close to the bottom of the bottle cap and the portion close to the bottom of the oil feeding cap are fixedly connected with a seal ring and a big seal ring respectively, so that the sealing effect of the oil bottle is remarkable; an air hole is formed in the bottle cap, the air hole is small so that oil pouring cannot be affected and harmful substances or dust cannot enter in use, and the oil quality is further ensured.

Owner:ANHUI CHUANGYUAN OILS CO LTD

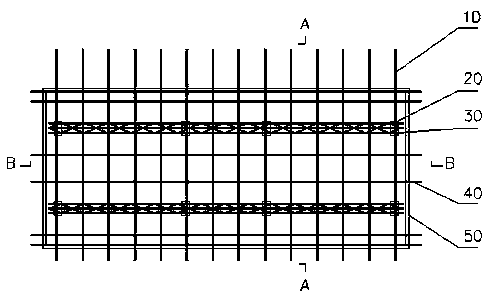

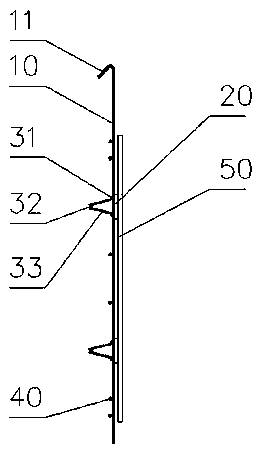

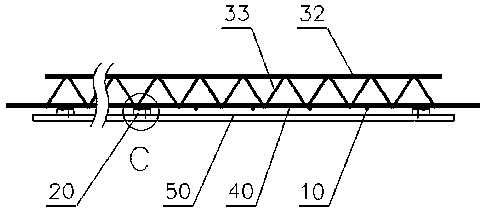

Non-dismounting nonmetal bottom plate solid mold composite slab, corresponding floor structure and floor construction method

PendingCN110499858ASimple processing equipment and processing technologyReduce the impactFloorsBuilding material handlingRebarEngineering

The invention discloses a non-dismounting nonmetal bottom plate solid mold composite slab, a corresponding floor structure and a floor construction method. The solid mold composite slab comprises a bottom plate, one reinforcing mesh and multiple steel bar trusses, wherein the reinforcing mesh and the multiple steel bar trusses are located above the bottom plate; the bottom plate is made of nonmetal materials, gaps are reserved between bottom plates of the steel bar trusses and the upper surface of the bottom plate, the floor takes the non-dismounting nonmetal bottom plate solid mold compositeslab as a permanent mold plate of a bottom mold, and a cast-in-place concrete layer is arranged on the permanent mold plate. According to the construction method, the non-dismounting nonmetal bottom plate solid mold composite slab serves as the permanent mold plate, a supporting system is arranged, the non-dismounting nonmetal bottom plate solid mold composite slab is mounted in place to form thefloor bottom mold, the cast-in-place concrete layer is poured on the bottom mold, and after solidification, the non-dismounting nonmetal bottom plate solid mold composite slab is not dismounted. The non-dismounting nonmetal bottom plate solid mold composite slab is simple in preparing process, short in production period, low in cost, and convenient to operate on the site construction, the formed floor meets the habitual texture of the person, and decoration is convenient.

Owner:ZHONGQINGDA TECH HLDG CO LTD +1

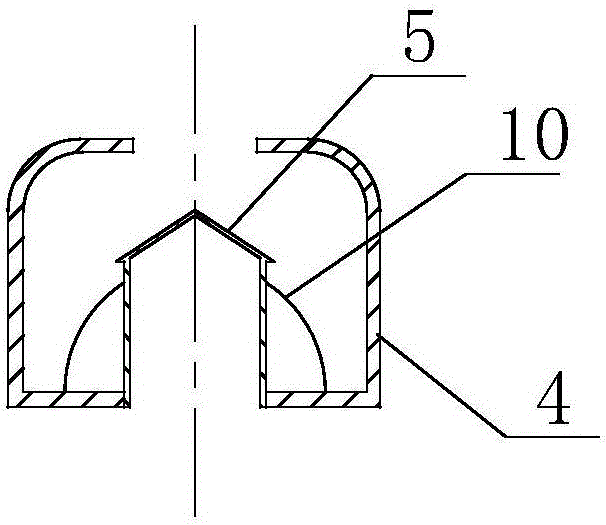

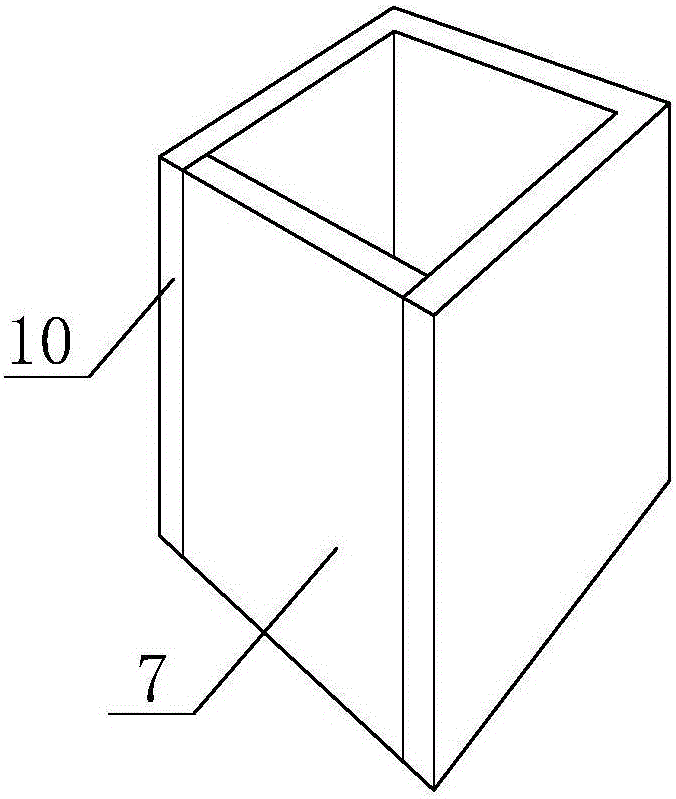

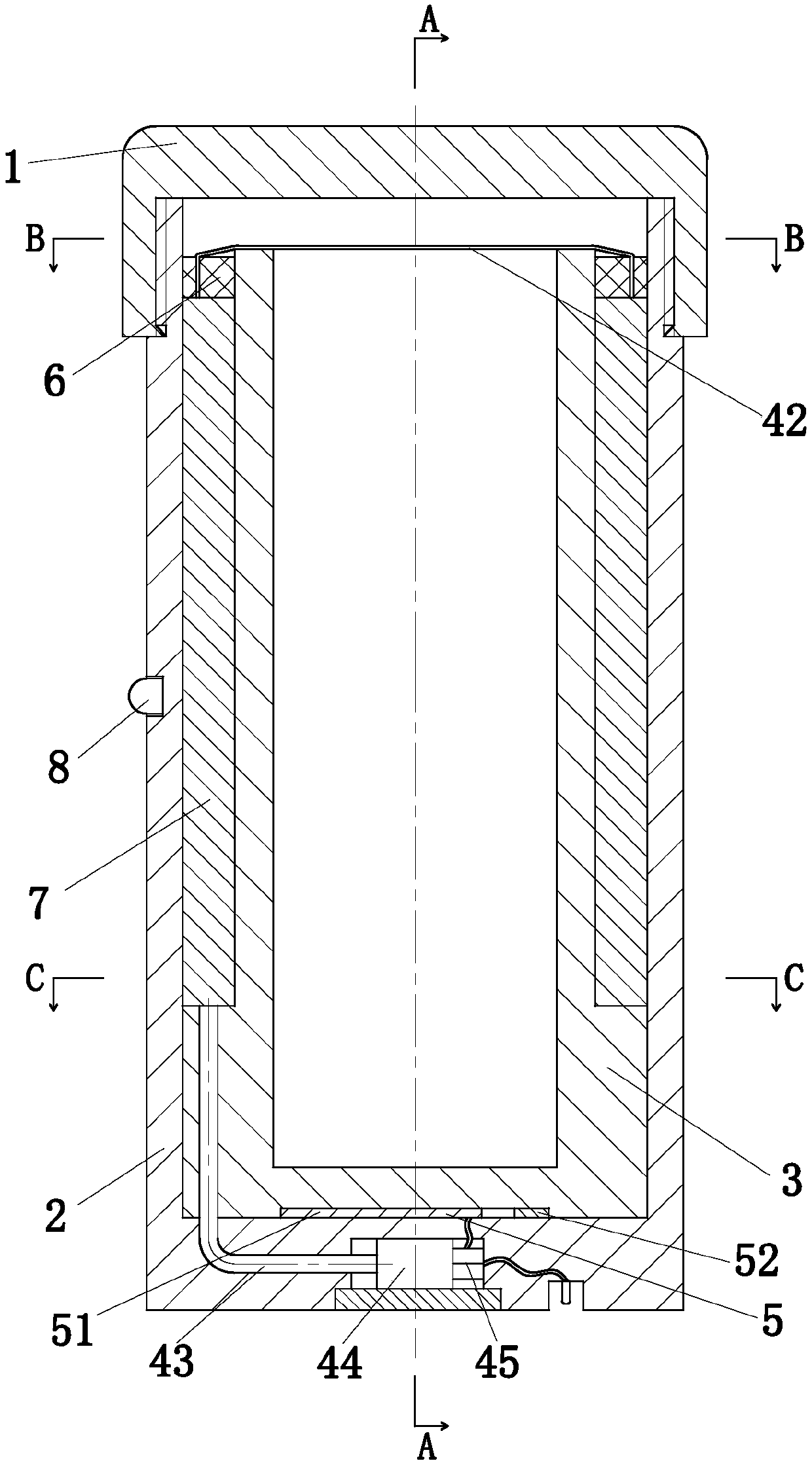

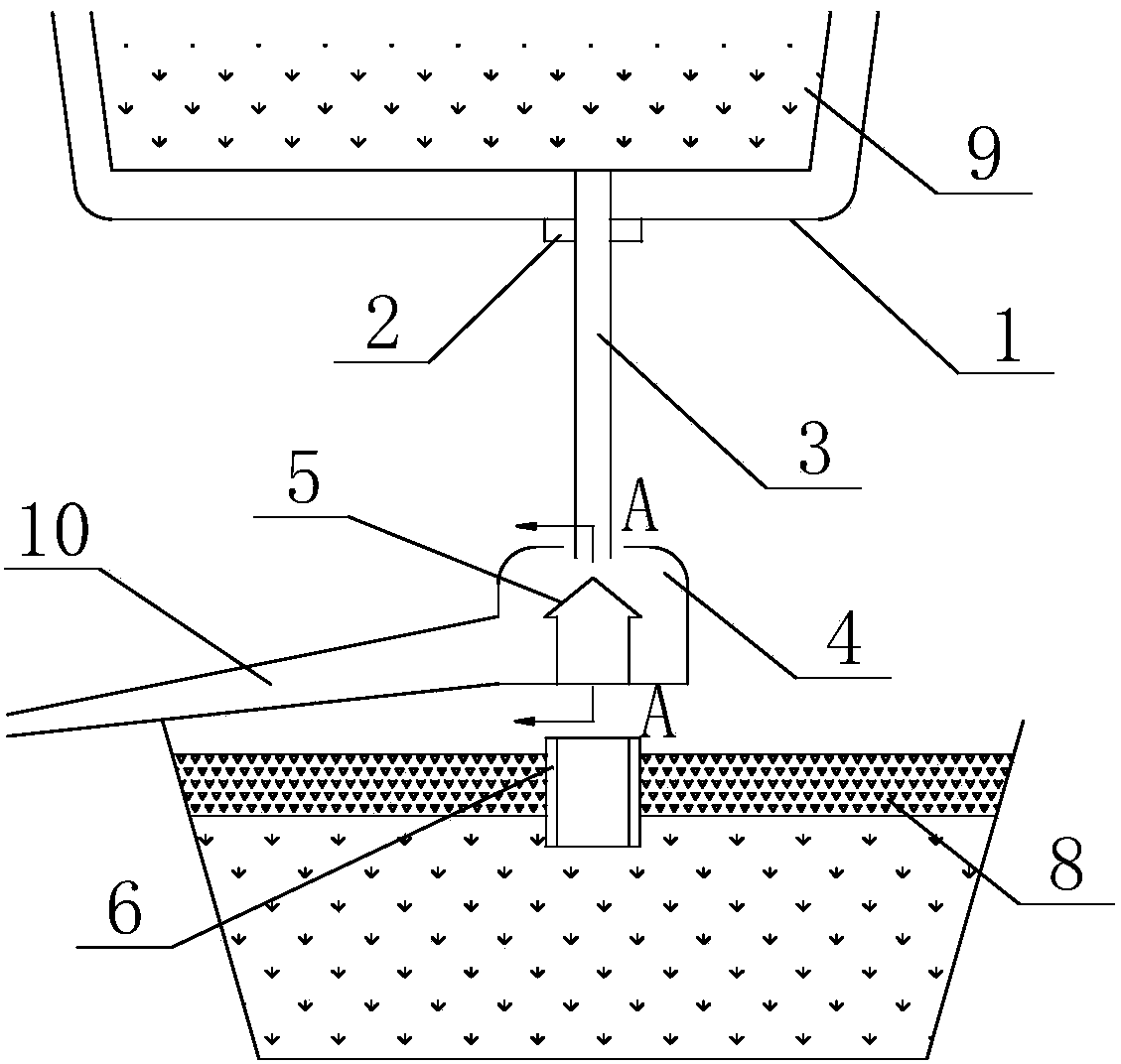

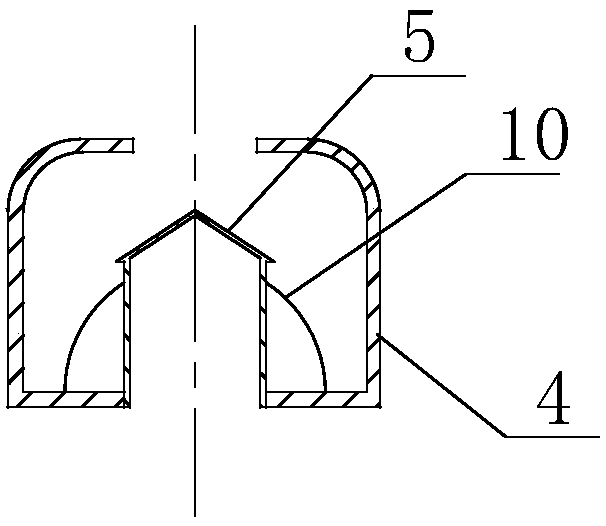

Joint of concrete filled steel tubular column

ActiveCN113006292AGood reinforcing effectImprove securityBuilding constructionsMechanical engineeringJoint (building)

The invention discloses a joint of a concrete filled steel tubular column. The joint comprises an upper steel pipe column and a lower steel pipe column which are vertically arranged, a U-shaped steel beam is horizontally arranged on the side wall of the lower steel pipe column, an open groove is formed in the side wall of the lower steel pipe column and corresponds to the steel beam, the open groove extends downwards from the upper end of the lower steel pipe column, the two sides of the open groove respectively form a connecting end, one end of the steel beam penetrates through the open groove, extends into the lower steel pipe column and is fixedly connected with the lower steel pipe column; a connecting plate is vertically arranged in the steel beam, and the connecting plate is fixedly connected with the steel beam; and the lower end of the upper steel pipe column is fixedly connected with the upper end of the upper steel pipe column. According to the joint, the joint of the steel pipe column and the steel beam is reinforced from the inside through the connecting plate, so that the appearance of the junction of the steel pipe column and the steel beam is smooth; and a standardized component inner sleeving process is adopted, adopted components, the steel pipe column and the steel beam can be installed in a factory, the production process and the installation process are convenient and fast, and a new thought is provided for the development direction of prefabricated buildings.

Owner:渝建建筑科技集团有限公司

A method for continuous casting ladle to keep molten steel clean

The invention relates to a method and a device for keeping molten steel clean in casting of a continuous casting ladle. When the ladle is cast, a slide water port is opened; a drainage agent flows out from the slide water port, flows onto a casting cap by a long water port of a middle ladle, and flows into a recoverer for recovery along the upper surface of the casting cap; after the drainage agent flows, the molten steel flows down; one part of the molten steel mixed with the drainage agent flows into the drainage agent recoverer along the upper surface of the casting cap; then, the casting cap is corroded by the molten steel for leaking, and the molten steel flows down; after one pot of steel is cast, the long water port is pulled out from the molten steel to deviate from the surface of middle ladle slag; a slag separator is pressed into the molten steel of the middle ladle through middle ladle slag; the side wall of the slag separator is pressed into the molten steel to stop the middle ladle slag from entering the slag separator; and the recoverer is replaced for casting a next ladle. The method and the device have the following advantages: the whole structure is simple; the operation is convenient; the drainage agent and the middle ladle slag can be effectively prevented from mixing into the molten steel of the middle ladle in casting of the ladle; the inclusion in steel is reduced; the steel quality is stable; and the variety quality is stable.

Owner:鞍山市华兴冶金炉料有限公司

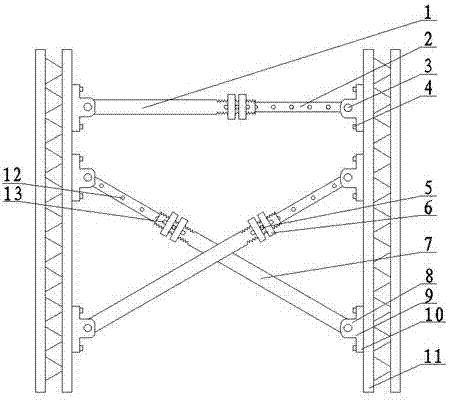

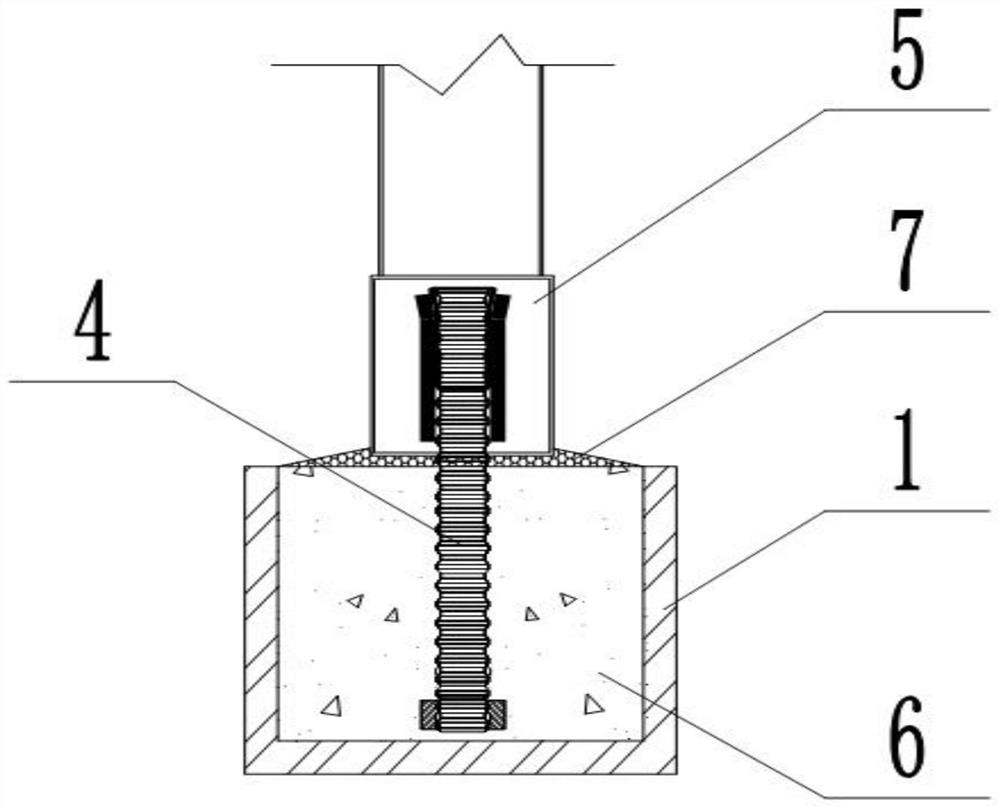

Utility tunnel prefabricated panel self-bearing support structure

PendingCN106930323AEasy to operateReduce installation errorsArtificial islandsUnderwater structuresWall plateArchitectural engineering

The invention relates to a utility tunnel prefabricated panel self-bearing support structure. The structure comprises at least two prefabricated panels which are oppositely arranged in parallel in a vertical mode; at least one horizontal support rod and at least one oblique support rod are arranged between the two prefabricated panels; sleeves are correspondingly pre-embedded into the two prefabricated panels respectively, and the two ends of each support rod are detachably connected with the corresponding sleeves pre-embedded into the two prefabricated panels through support rod connecting bases respectively to form one horizontal support rod or oblique support rod; the length of the support rods can be adjusted. According to the structure, the prefabricated panels are detachably connected through the support rods and the support rod connecting bases, the overall strength of the structure is high, the risk that a single panel collapses and potential safety hazards are excluded, pouring of a base plate is not influenced, and the support rods and the support rod connecting bases can be reused.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

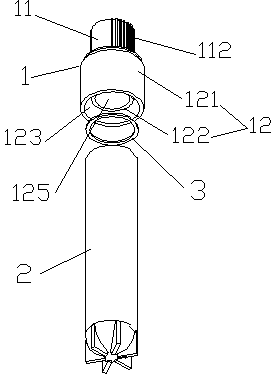

Improved structure of freeze pipe cover

ActiveCN104206377APouring will not affectImprove sealingDead animal preservationEngineeringScrew thread

The invention belongs to the field of medical devices, particularly to an improved structure of a freeze pipe cover. The improved structure of the freeze pipe cover comprises a cover body and a pipe body, wherein the cover body is composed of a twisting unit and a screw unit, and the screw unit comprises an outer protector and an inner screwing body; a tubular cavity is formed between the outer protector and the inner screwing body; the outer circumference of the inner screwing body is provided with external threads, and the mouth of the pipe body is provided with internal threads. The improved structure of the freeze pipe cover greatly reduces the possibility of contamination, achieves good sealing effects, avoids influence on pour-out of materials inside the pipe, facilitates screwing operations, obtains high strength, saves materials and is low in manufacturing costs.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

Unsupported disassembly-free concrete hole forming method

ActiveCN110080522ASave labor resourcesLiberate labor intensityForms/shuttering/falseworksThermal insulationHole size

The invention discloses an unsupported disassembly-free concrete hole forming method. The method comprises the following steps: carrying out on-site lofting on the size of a concrete hole according toa design drawing and a concrete pouring construction condition; simply reinforcing a thermal insulation material according to the field setting-out size in combination with the thickness of the thermal insulation material under the condition of not occupying the boundary line of the hole size structure; setting out the size of a water outlet bag according to the actual size of the concrete hole,and laying the water outlet bag into the hole thermal insulation material; arranging a plurality of refrigeration instruments in the water bag in the hole thermal preservation material, introducing water into the water bag to a certain volume, starting refrigeration equipment, and refrigerating water in the water bag to be in an icing state through the refrigeration instruments in the water bag; according to the concrete construction progress outside the hole, slowly filling the remaining volume of the water bag with water, and gradually filling full the water bag to ensure that the icing bodydoes not occupy the boundary line of the hole size structure; and after the concrete around the holes reaches the mold stripping age, shutting down the freezing equipment, the ice gradually melting into water, and taking out the thermal preservation material.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

A double pipe centering device and its realization method

The invention discloses a double-tube centering device. The double-tube centering device comprises T-shaped connecting parts, a fastening bolt, an adjustable bolt, a puller bolt, a long nut, a fixing bolt, an inner tube, an outer tube and a bottom plate, wherein the inner tube and the outer tube are both arranged on the bottom plate; the inner tube is located in the outer tube, and a space is reserved between the inner tube and the outer tube; and all the multiple T-shaped connecting parts are arranged on the bottom plate and arranged on the periphery of the outer tube. The double-tube centering device can be suitable for double-tube structure parts with various different tube diameters and tube thicknesses, different structure part section hollow rates, different tubes and different section shapes. The device is reasonable in design, ingenious in size, simple in structure, low in cost, high in repeated utilization rate, easy to operate and high in reliability and does not influence concrete pouring in tubes, and used materials can be obtained conveniently and rapidly.

Owner:中穗丰华建设咨询有限公司

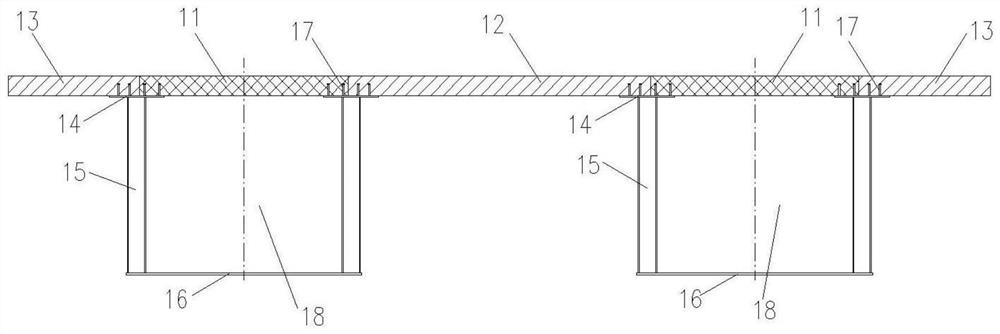

Simply supported and continuous corrugated web steel box-concrete composite beam

PendingCN113279316AEasy to processEnhanced out-of-plane stabilityBridge structural detailsBridge erection/assemblyArchitectural engineeringContinuous beam

The invention relates to the field of bridges, and in particular relates to a simply supported and continuous corrugated web steel box-concrete composite beam. The simply supported and continuous corrugated web steel box-concrete composite beam comprises a plurality of prefabricated corrugated web steel box-concrete composite beams, the prefabricated corrugated web steel box-concrete composite beams are connected through steel box type cross beams and K-shaped steel cross beams in the transverse bridge direction, composite beam reinforced concrete top plates are connected through cast-in-place reinforced concrete plates, cast-in-place reinforced concrete side wing plates are poured on the outer sides of the composite beam reinforced concrete top plates, the continuous ends of the multiple prefabricated corrugated web steel box-concrete composite beams in the longitudinal bridge direction are connected through cast-in-place concrete connecting sections, the cast-in-place concrete connecting sections are connected with open corrugated web steel boxes through studs, supports are arranged below the cast-in-place concrete connecting sections, and the simply supported and continuous corrugated web steel box-concrete composite beam is formed. The advantages of corrugated steel webs and the excellent stress characteristic of continuous beams are fully utilized, the self weight is light, machining and manufacturing are easy, the construction quality is guaranteed, the bridge construction speed is high, and very wide practicability is achieved.

Owner:甘肃省交通规划勘察设计院股份有限公司

Lifting hook bridge crane of double generator operation mechanism

InactiveCN1907835ADoes not affect pouringShort stayTravelling cranesTravelling gearStop timeElectric machinery

The invention relates to a hook bridge crane with double motors, wherein said crane is characterized in that: its operator is formed by two motors and dual-output-axle speed reducer; two motors are connected to left and right input axles of speed reducer; the power wires of two motors are connected to one switch; and it commonly uses one motor; when there is accidence, it switches to another motor, with short stop time without affecting the irrigation of steel liquid.

Owner:张树文

Water stacking structure of movable gate

PendingCN110735421AContinuous cascading landscapeStable cascading landscapeBarrages/weirsLiquid spraying apparatusEngineeringStructural engineering

The invention discloses a water stacking structure of a movable gate. The movable gate comprises a gate leaf, and the water stacking structure is arranged on the gate leaf of the movable gate. The water stacking structure further comprises a water stacking plate and a driving mechanism, the driving mechanism drives the water stacking plate to enter a water stacking plate opening position or a water stacking plate closing position, and the driving mechanism comprises a driving device, a first connecting rod and a second connecting rod. The water stacking plate comprises a first water stacking plate connecting point and a second water stacking plate connecting point. One end of the driving device is connected with the gate leaf, and the other end of the driving device, one end of the first connecting rod and one end of the second connecting rod are connected to the same rotating point. The other end of the second connecting rod is connected with the gate leaf, the first water stacking plate connecting point is connected with the door leaf, the second water stacking plate connecting point is connected with the first connecting rod, and a locking device is further included and used forlocking the water stacking plate. According to the water stacking structure, the movable gate is improved, a water stacking landscape is added, and the water stacking plate can be driven by the driving mechanism to contract; and the locking device can be additionally arranged to lock the position of the water stacking plate, and normal flood discharge and water retaining of the gate are not influenced.

Owner:扬州市嵩峰机械加工有限公司

Adjustable window frame mounting and build-in construction method

PendingCN114658322AThe installation position can be adjustedQuick installationFrame fasteningSills/thresholdSash windowArchitectural engineering

The invention discloses an adjustable window frame mounting and build-in construction method. A window frame with an adjusting function, a windowsill coping pre-built by U-shaped precast blocks and a stile are included. The windowsill coping can be built firstly, then the stile is built, then the window frame is installed according to needs, the window frame is matched with the windowsill coping and the stile built by the U-shaped prefabricated blocks, the adjusting function of the window in the installation process can be achieved, the installation precision is effectively improved, meanwhile, the window sash can be effectively supported, and deformation and looseness of the window sash can be prevented.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

An Improved Structure of a Cryopreservation Tube

ActiveCN103918643BSolve the defects that are easy to fallImprove sealingDead animal preservationEngineeringScrew thread

The invention belongs to the field of medical instruments, and particularly relates to an improved structure of a cryopreserved tube. The improved structure comprises a tube body and a tube cap, wherein the tube cap is connected with the tube body in an inner rotating manner; the tube cap is provided with an external thread; a tube opening of the tube body is provided with an internal thread; the internal thread is an internal thread section or an internal thread point provided with a notch therebetween. The cryopreserved tube provided by the invention is good in sealing effect, does not influence the pouring of substances inside the tube, is easy to screw, high in strength, has a mark classification function, saves the material, and is low in manufacturing cost.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

A method for forming concrete holes without support and without demolition

ActiveCN110080522BAvoid wastingSave labor resourcesForms/shuttering/falseworksThermal insulationArchitectural engineering

The invention discloses an unsupported disassembly-free concrete hole forming method. The method comprises the following steps: carrying out on-site lofting on the size of a concrete hole according toa design drawing and a concrete pouring construction condition; simply reinforcing a thermal insulation material according to the field setting-out size in combination with the thickness of the thermal insulation material under the condition of not occupying the boundary line of the hole size structure; setting out the size of a water outlet bag according to the actual size of the concrete hole,and laying the water outlet bag into the hole thermal insulation material; arranging a plurality of refrigeration instruments in the water bag in the hole thermal preservation material, introducing water into the water bag to a certain volume, starting refrigeration equipment, and refrigerating water in the water bag to be in an icing state through the refrigeration instruments in the water bag; according to the concrete construction progress outside the hole, slowly filling the remaining volume of the water bag with water, and gradually filling full the water bag to ensure that the icing bodydoes not occupy the boundary line of the hole size structure; and after the concrete around the holes reaches the mold stripping age, shutting down the freezing equipment, the ice gradually melting into water, and taking out the thermal preservation material.

Owner:CHINA THREE GORGES PROJECTS DEV CO LTD +1

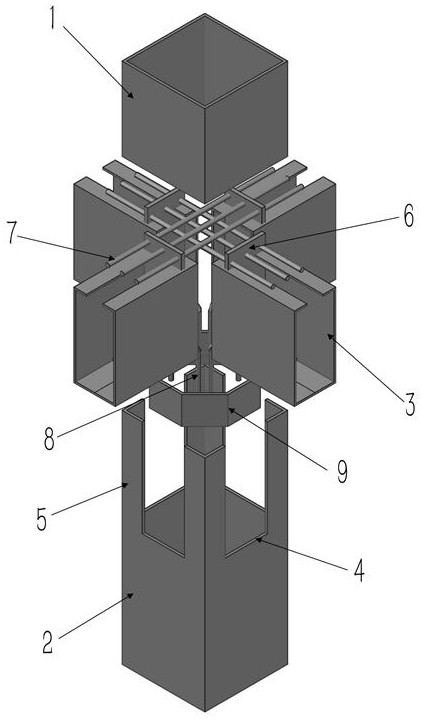

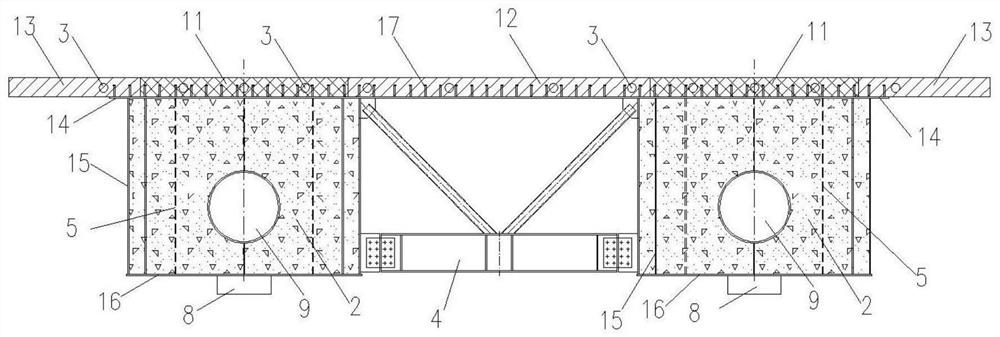

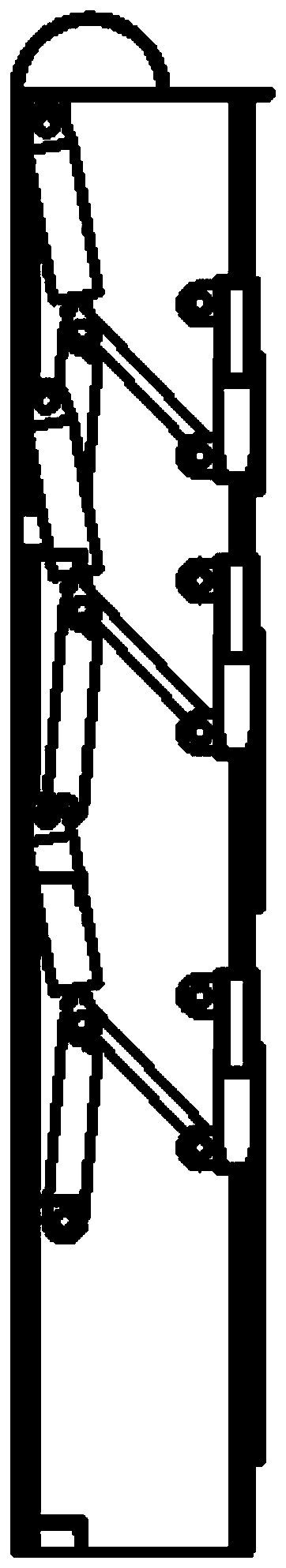

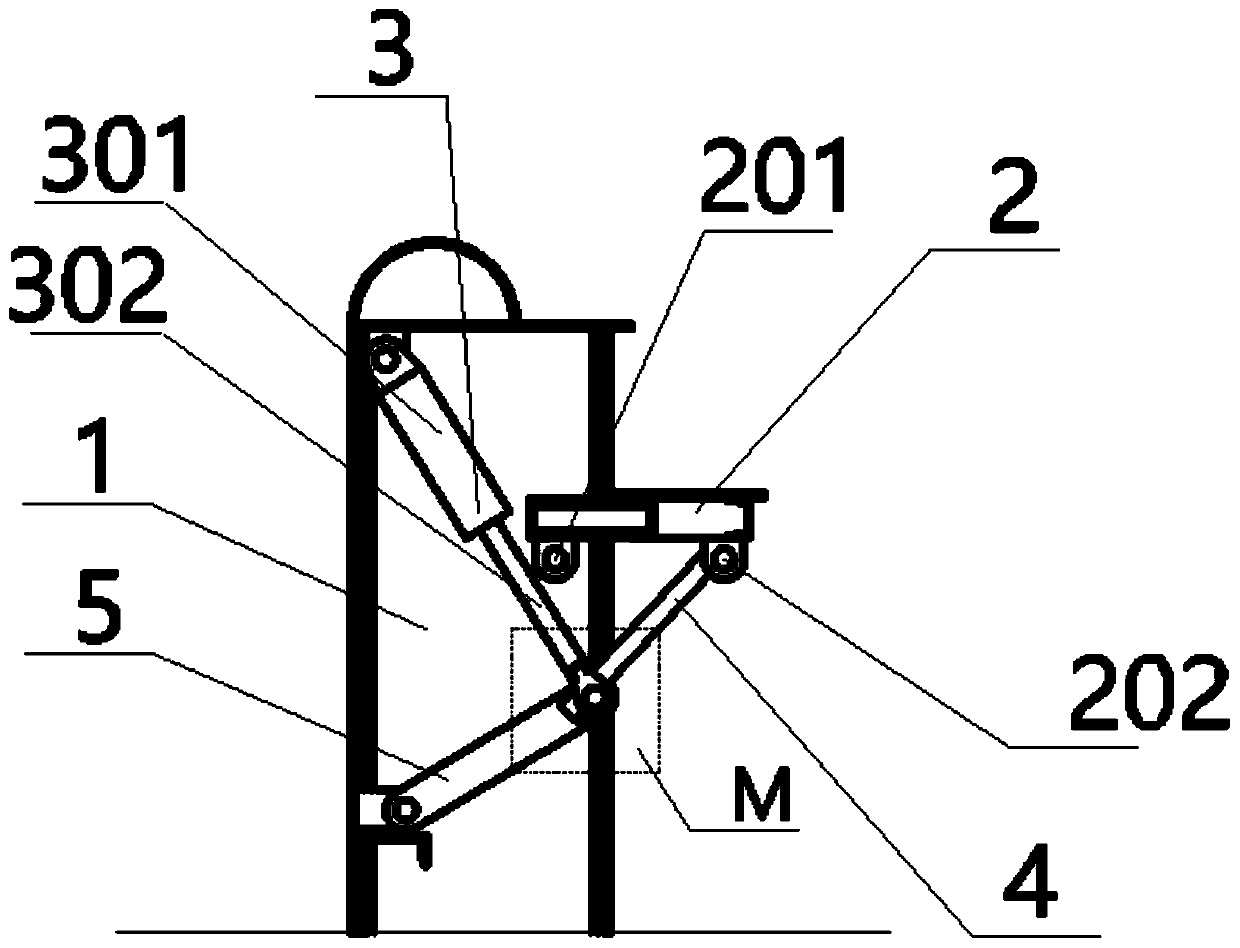

An inner diaphragm type concrete filled steel pipe transfer node structure and its construction method

ActiveCN105239668BReduce section sizeEfficient use ofBuilding constructionsQuality assurancePlate column

The invention discloses an inner diaphragm type concrete-filled steel pipe transfer node structure and a construction method thereof, wherein an inner diaphragm type steel pipe concrete transfer node structure includes a pillar, a slanted column and a socket for connecting the slanted column to the pillar There is a section on the inclined column, and the section includes a cross section. The receiving frame is fixedly arranged inside the pillar and is located at the top of the pillar. The receiving frame includes a lower inner partition and a vertical inner rib, and the vertical inner rib is fixed on the On the lower inner partition, the shape of the vertical inner rib corresponds to the cross-sectional shape of the oblique column, and the oblique column is fixed to the vertical inner rib through the section. The invention combines the advantages of the steel pipe concrete and inclined column conversion structure, and has the advantages of direct force transmission, high bearing capacity, small component cross-sectional size, favorable use of building space, no need for formwork, less on-site welding workload, and guaranteed construction quality, etc. advantage. The two slanted columns and the beam system constitute a triangular force transmission mode, and have good resistance to lateral forces.

Owner:SOUTH CHINA UNIV OF TECH

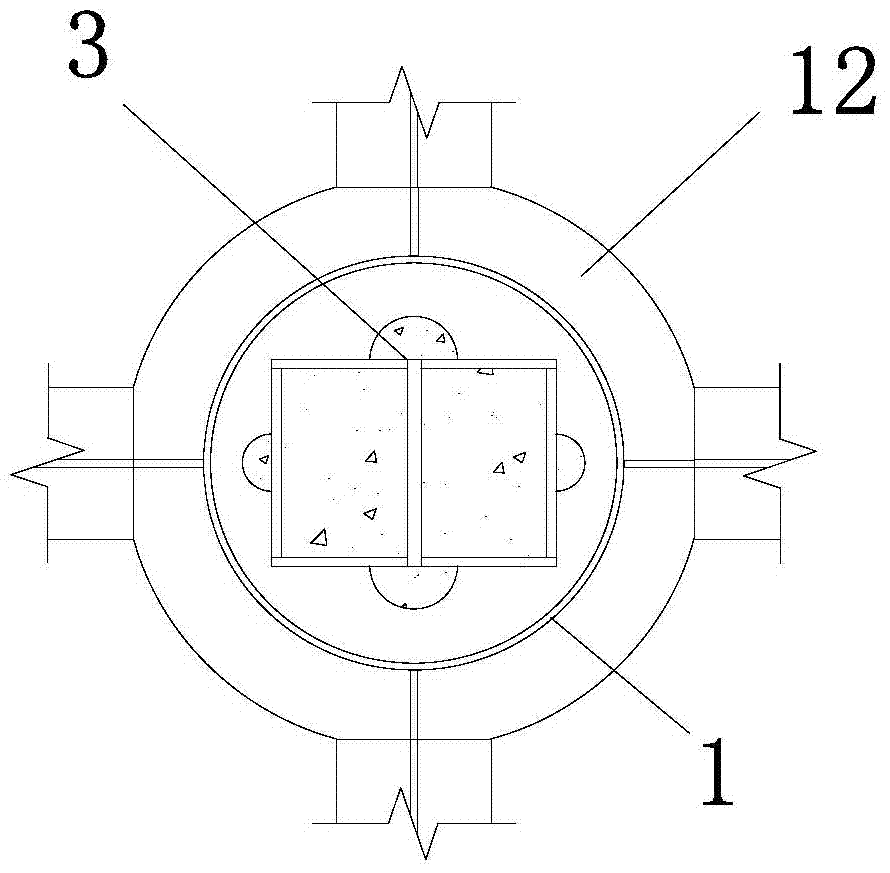

Hollow sandwich filled steel tubular column-steel beam node adopting one-way fastening bolt

The invention relates to the field of structural engineering in civil engineering, in particular to a hollow sandwich filled steel tubular column-a steel beam connection adopting a one-way fastening bolt. The one-way fastening bolt component passes through an inner steel tube and an outer steel tube on one side, one end of an end plate component is abutted against the wall of the outer hollow sandwich filled steel tube, and an inner steel tube and an outer steel tube on the other side are connected with a steel beam. During construction, the inner steel tubes and the outer steel tubes are preserved with holes; then the bolt component passes through the end plate and the holes on the steel tubes and is screwed; and finally, sandwich concrete is poured to finish the construction of the connection. The connection has definite force transmission, reliable performance, convenient construction and good economy and is suitable for high-rise and large-span buildings and other relevant buildings.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com