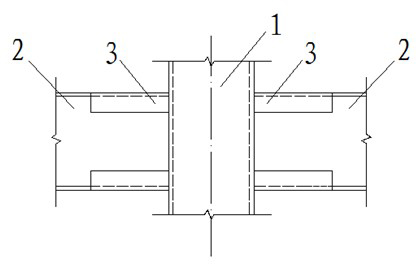

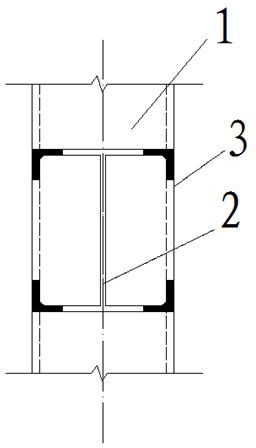

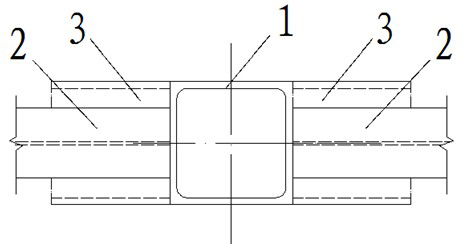

Connecting node of square steel pipe column, H-shaped steel beam and L-shaped ribbed plate

A technology for connecting nodes and square steel pipes, applied in the direction of buildings, building structures, etc., can solve problems such as affecting the construction of upper floor slabs, and achieve the effects of avoiding construction difficulties, convenient construction, and enhancing joint stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0018] The two limbs of the L-shaped rib plate 3 are respectively connected to the upper and lower flanges of the H-shaped steel beam 2 and connected to the wall plate of the square steel pipe column 1, wherein the width B of the flange of the H-shaped steel beam 2 is twice the width B of the L-shaped steel beam connected to it. Limb length b 1 of and. The square steel pipe columns 1 include cold-formed rectangular square steel pipe columns and hot-rolled square columns; the H-shaped steel beams 2 include hot-rolled H-shaped steel beams and welded H-shaped steel beams; the L-shaped ribs 3 are Hot-rolled angle steel, but when hot-rolled L-shaped steel angle matching H-shaped steel beams cannot be realized, welded L-shaped ribs can be used.

[0019] There are four L-shaped ribs 3 mentioned above, which are arranged symmetrically on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com