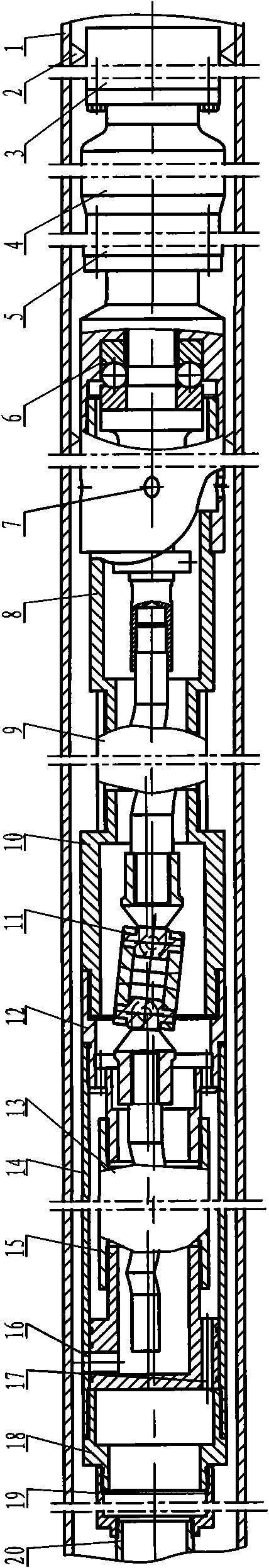

Double-inlet and single-outlet submersible screw pump oil extraction device

A technology of submersible screw and oil production device, which is applied in the direction of pumps, production fluids, earthwork drilling and production, etc. It can solve the problems of short service life of bearings, achieve the effects of reducing maintenance costs, increasing service life, and reasonable force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] according to figure 1 The specific structure of the present invention will be described in detail. The double-inlet and single-outlet submersible screw pump oil production device is lowered into the well pipe 1 of the oil field for operation, and the device is centered and fixed in the well pipe 1 by using the anchor 2 . It includes submersible motor 3, planetary reducer 4, oil protector 5, thrust coupling 6, transition sleeve 8, lower screw pump 9, sink body 10, universal Coupling 11, guide body 12, upper screw pump 13, spacer body 14, shunt sleeve 15, compression sleeve 18, oil outlet check valve 19 and oil delivery pipe group 20 and other parts. Wherein some parts, as the structures of anchor 2, submersible motor 3, universal coupling 11, 18 compression sleeves, oil outlet check valve 19, oil delivery pipe group 20 etc. basically adopt common parts, some parts are different from this Some components in the inventor's previous patent "Mechanical Transmission Device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com