An Efficiency Optimal Control Method for Two-stage Converter

A converter and efficiency technology, applied in the direction of DC power input conversion to DC power output, AC power input conversion to DC power output, control/regulation system, etc., can solve the problem of affecting system efficiency, reducing system efficiency, front-end It is difficult to achieve efficiency optimization and other issues for the flow device to achieve the best efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

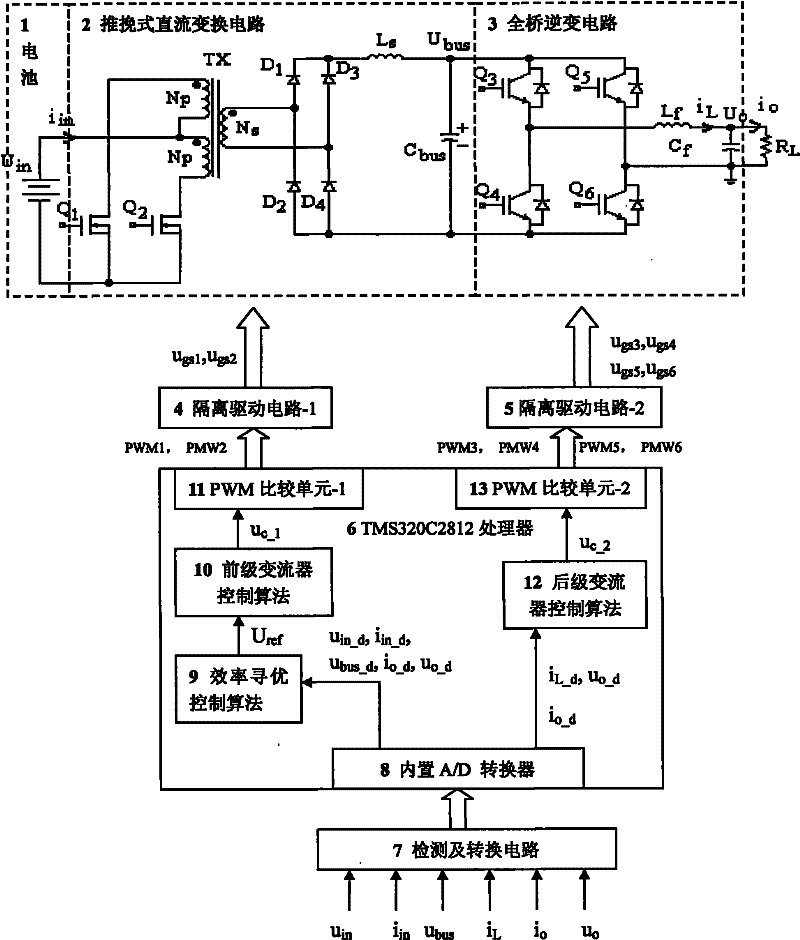

[0022] The following is attached image 3 A specific embodiment of the present invention is described in further detail.

[0023] see image 3 , which is a vehicle-mounted inverter adopting an efficiency optimization control method according to the present invention. The circuit is mainly composed of the following parts: 1 12VDC lead-acid battery pack; 2 push-pull DC converter; 3 full-bridge inverter circuit; 4 isolated drive circuit-1; 5 isolated drive circuit-2; 6 TMS320C2812 processor; 7 Detection and conversion circuit;

[0024] The 1 12VDC lead-acid battery pack voltage U in The allowable variation range is 10VDC~15VDC;

[0025] The power transistor Q in the 2 push-pull DC converters 1 and Q 2 Five IRF3205s are used in parallel, the ratio of the primary and secondary sides of the transformer is 2:72, and the diode D 1 ~D 4 RHRP8120 is used. Inductance Ls is 1mH. The circuit switching frequency is 30kHz. Intermediate bus capacitance C bus It is 1000uF / 500VDC, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com