Liquid water resistant and water vapor permeable garments comprising hydrophobic treated nonwoven made from nanofibers

A technology of nanofibers and nanofiber layers, which can be used in non-woven fabrics, protective clothing, textiles and papermaking, and can solve problems such as low air permeability and discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

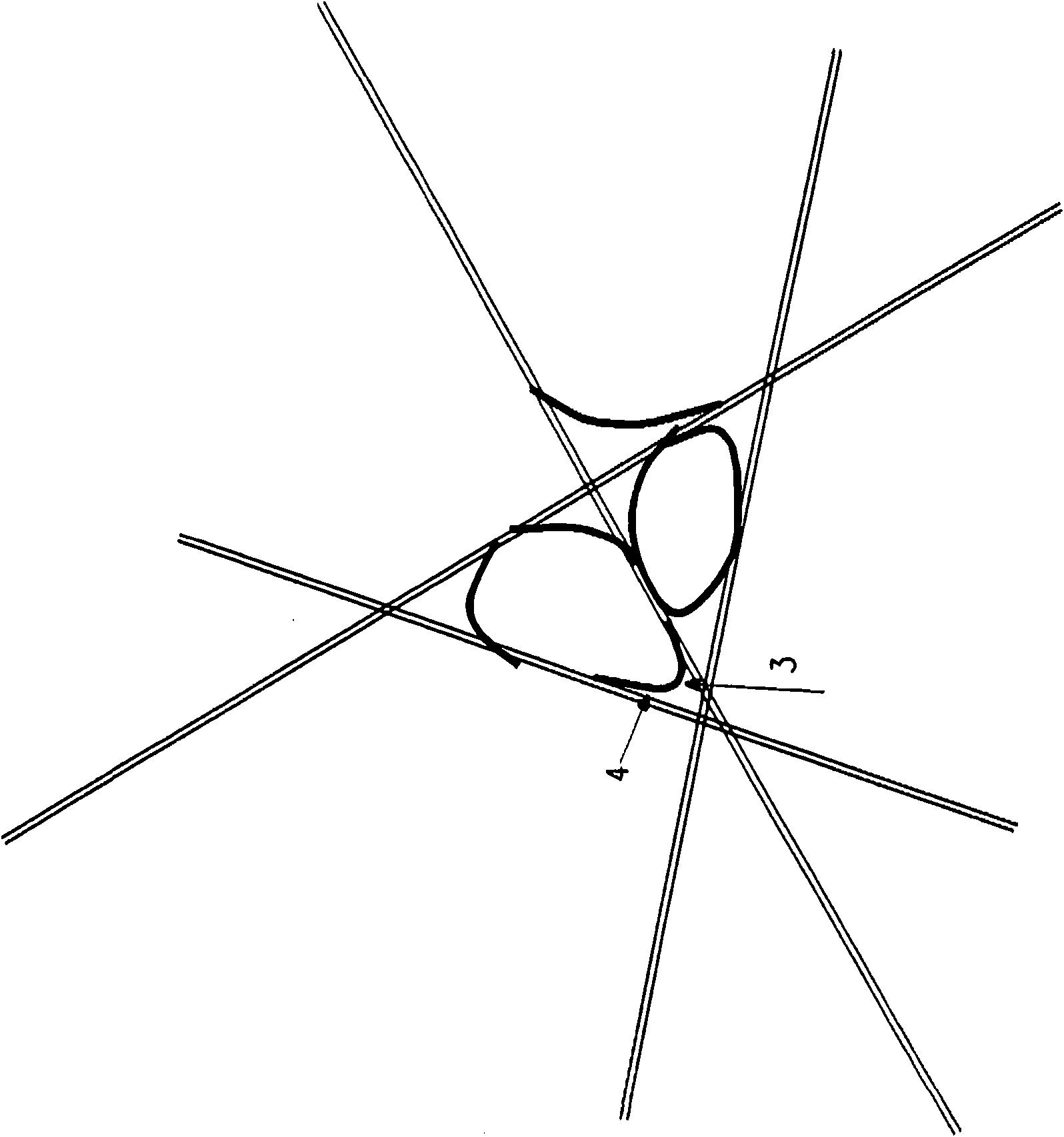

Image

Examples

Embodiment

[0034] hydrostatic head or "Static Head" (ISO 811) is a convenient measure of a fabric's ability to penetrate water against water. It is expressed in centimeters of water column (cmwc) required to force liquid water through the fabric. It is known that the static head depends on the inverse of the pore diameter. Smaller pore sizes produce higher static head, while larger pore sizes produce lower static head. In the following measurements, a ramp rate of 60 cmwc per minute was used.

[0035] Fraser air permeability It is measured according to ASTM D737. In this measurement, 124.5 N / m is applied to a properly clamped fabric sample 2 (0.5 inches of water column) pressure difference, the resulting air flow rate is measured and expressed in m 3 / min / m 2 Make a note.

[0036] moisture vapor transmission rate ("MVTR") is measured in accordance with ASTM E96 B and is expressed in units of g / m 2 / day for recording.

[0037] Contact angle Measured using a Video Contact A...

Embodiment 1

[0044] Prepare the nanofiber layer in the same manner as above and use 7040, the difference is that melamine formaldehyde resin ( 2003 from Bercen, Inc., Cranston, Rhode Island). The ratio of 7040 to melamine formaldehyde resin is about 3:1.

[0045] The treated nanofiber layer was placed in a test fixture, and then the properties were measured according to the method in Comparative Example 1. The static pressure head, Frazier air permeability and moisture vapor transmission rate of the nanofiber layer were measured, and the measurement results are shown in Table 1.

[0046] Two samples of the nanofibrous layer were prepared, and then three contact angle measurements were made for each sample according to the method in Comparative Example 1. The measurement results are shown in Table 1.

[0047] Table 1

[0048] Example

[0049] As can be seen from the data, the treatment bath containing melamine formaldehyde resin significantly increased the hydrostatic he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tenacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com