Inner shoe

A technology for inner shoes and ski shoes, applied in the field of inner shoes, can solve problems such as discomfort, and achieve the effect of easy integration or positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

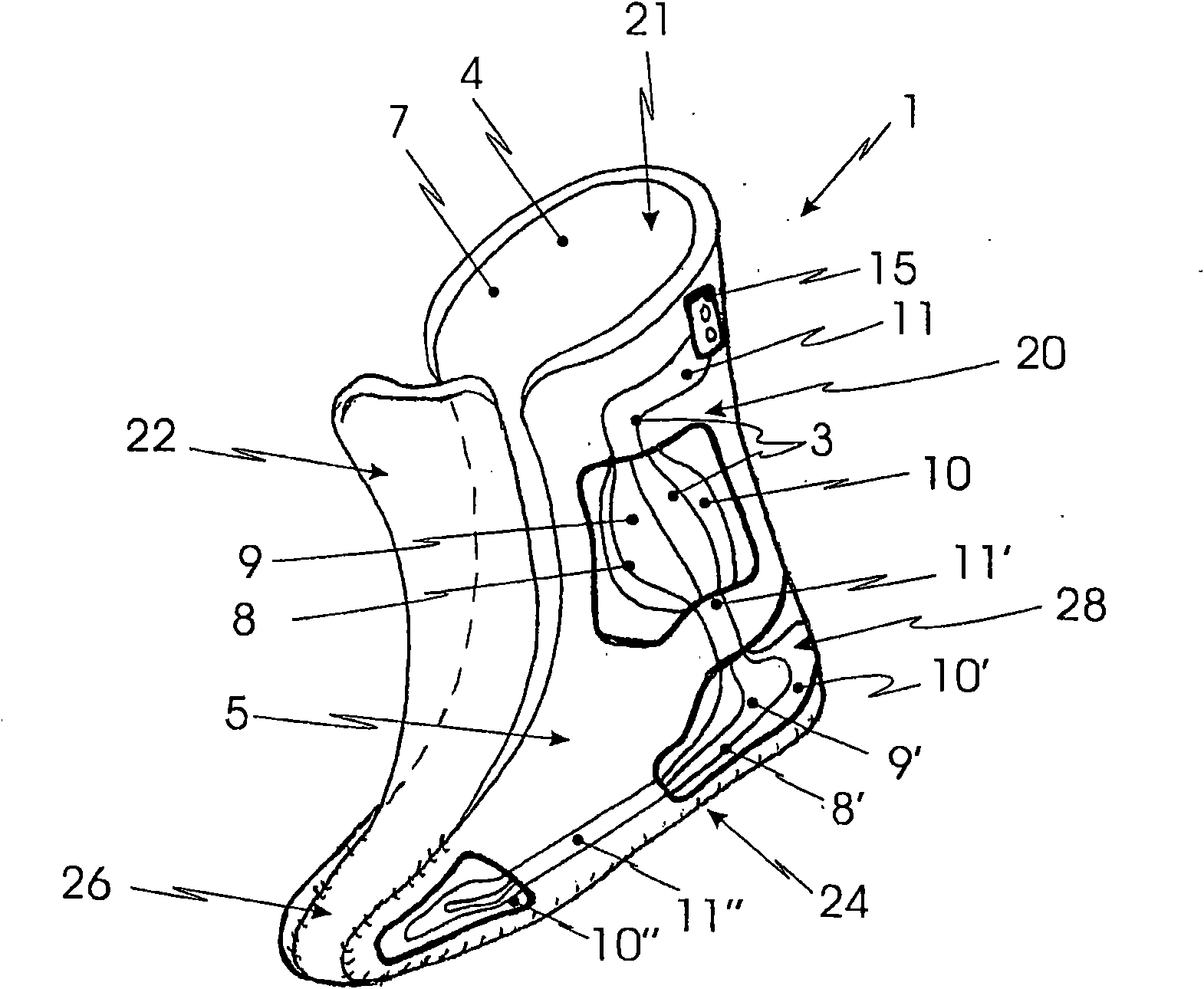

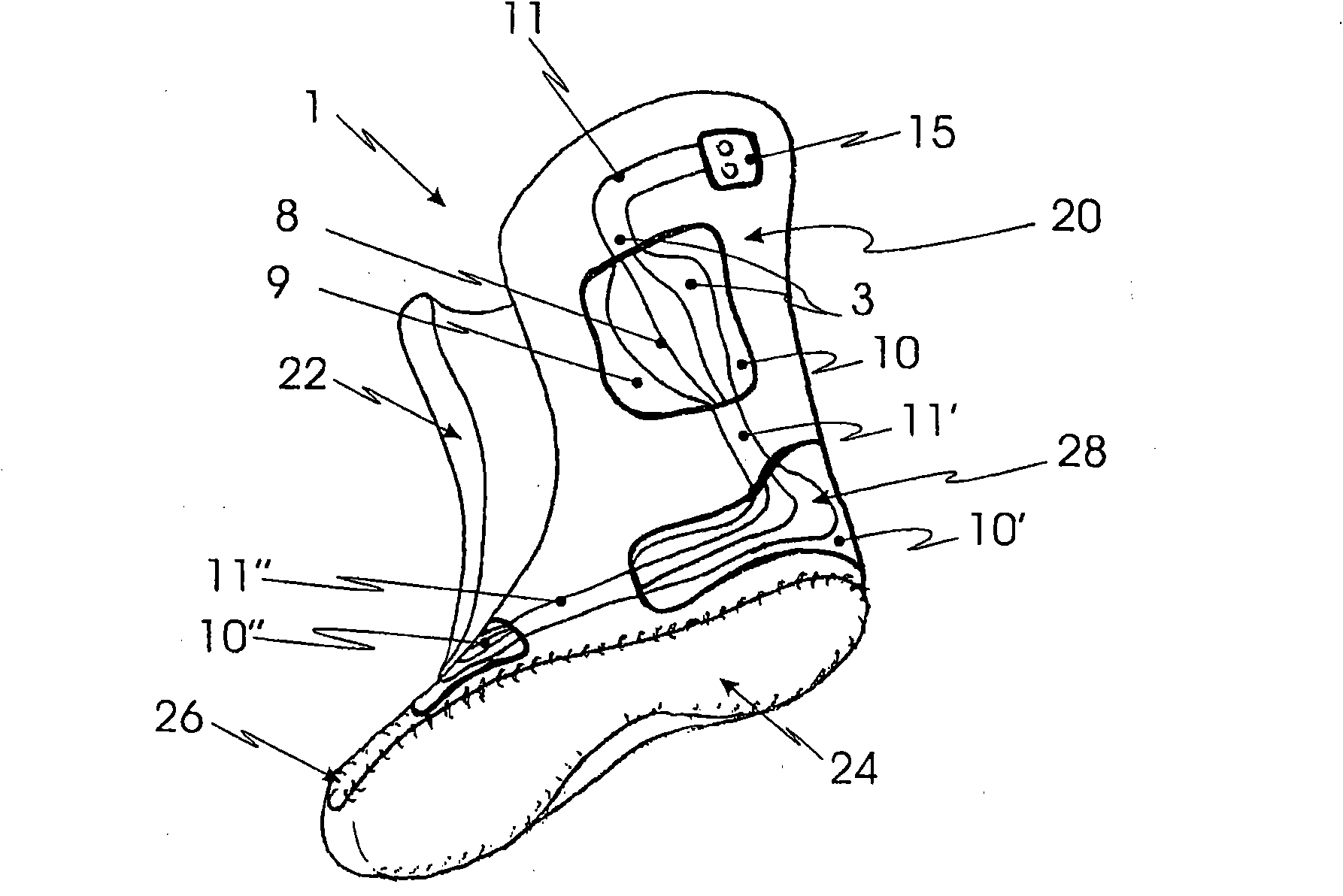

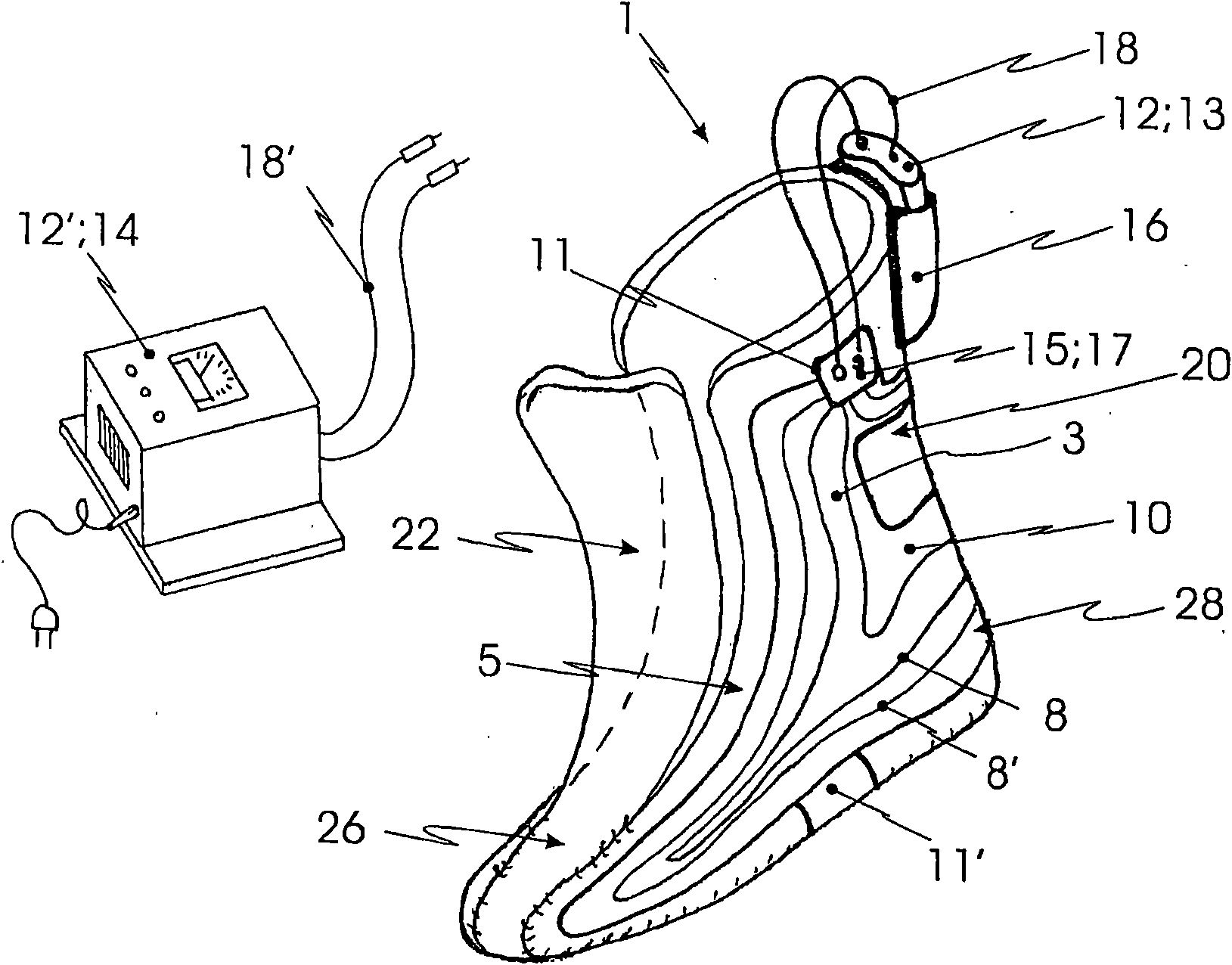

[0031] figure 1 and 2 A first embodiment of the inner shoe 1 according to the invention is shown. It consists here of a foamed plastic base material 4 , onto which an inner lining 7 is applied to the inner region 21 of the inner shoe 1 . The inner shoe 1 here comprises, for example, a shaft 20 , a tongue 22 , which merges via a forefoot region 26 or a heel region 28 into a sole region 24 .

[0032] In order to adapt the inner shoe 1 to a wearer's foot optimally, it at least partially comprises a thermoplastic matrix material 4 which is heated to a predetermined deformation temperature T V , in this case approximately 100-120° allows plastic deformation of the matrix material. Once the wearer puts on the inner shoe 1, it begins to adapt it to the outer contour of the foot. Here it is possible for the inner shoe 1 to be provided with a plastically deformable material only in defined regions, or, as is the case here, to be produced entirely from such a thermoplastic.

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com