A conduction-cooled superconducting magnet based on rebco-coated superconducting sheets

A superconducting magnet, conduction cooling technology, applied in superconducting/high-conducting conductors, superconducting magnets/coils, usage of superconducting elements, etc., can solve the immature development of joint welding technology, increase the operating cost of refrigeration system, magnetic field attenuation obvious problems, to achieve the effect of wide adjustment temperature range, simple structure and improved cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

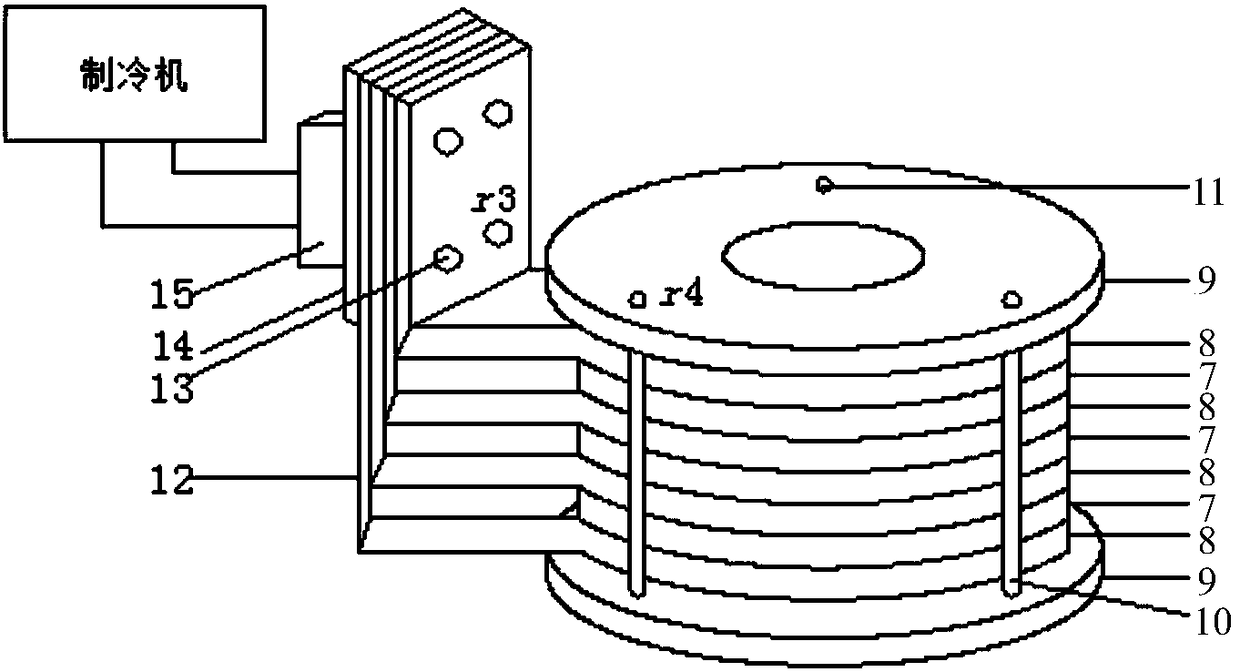

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

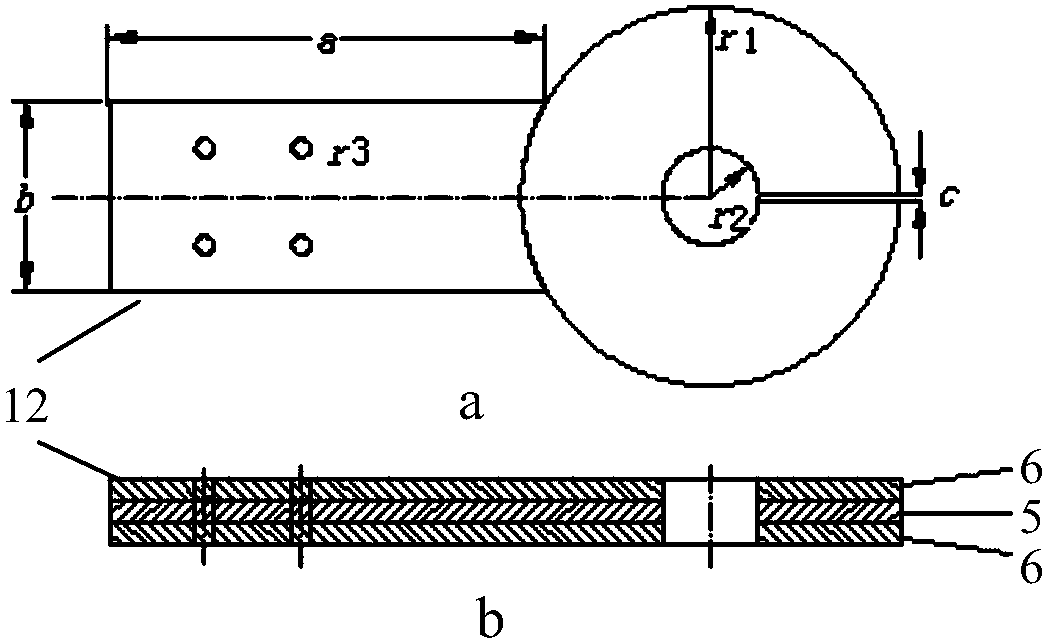

[0032] First prepare superconducting sheet 7 and cooling sheet 8, as follows:

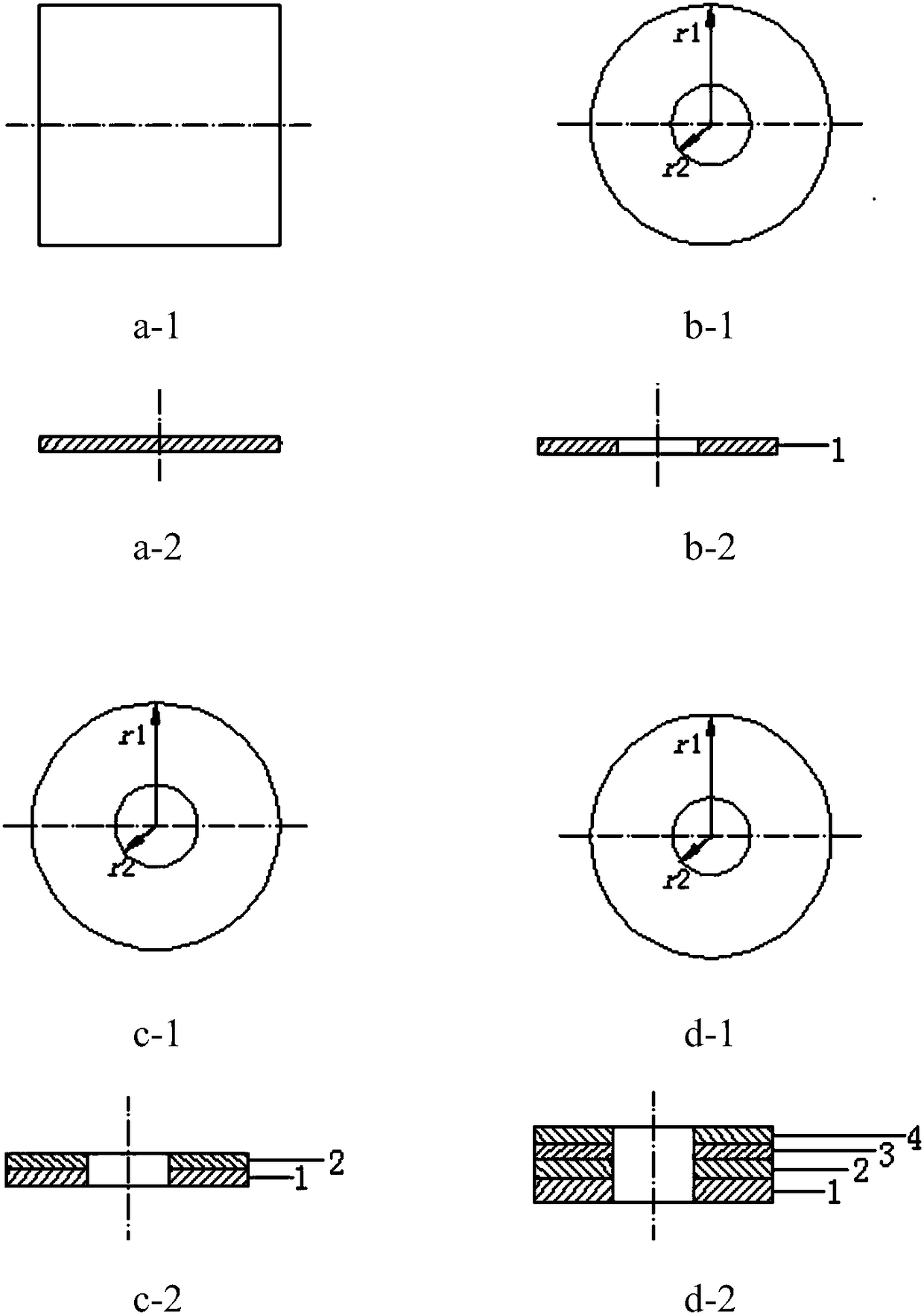

[0033] 1. The processing flow of superconducting sheet 7 based on ReBCO coating is as follows figure 1 shown.

[0034] (1) The material of substrate 1 adopts but is not limited to Ni, NiW, Hastelloy or stainless steel, firstly make such as figure 1 a-1 and figure 1 The semi-finished square sheet substrate shown in a-2;

[0035] (2) Cut the semi-finished square sheet substrate into a circular sheet with an inner radius of r2 and an outer radius of r1 to obtain the following: figure 1 b-1 and figure 1 Substrate 1 shown in b-2;

[0036] (3) Using processes such as ion beam assisted deposition (IBAD), inclined substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com