Preparation of vo by hydrogen reduction of ammonium polyvanadate 2 method and heat sensitive device

An ammonium polyvanadate, VO2 technology, applied in the direction of measuring devices, using electrical devices, thermometers with electrical/magnetic components directly sensitive to heat, etc., to achieve the effect of easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

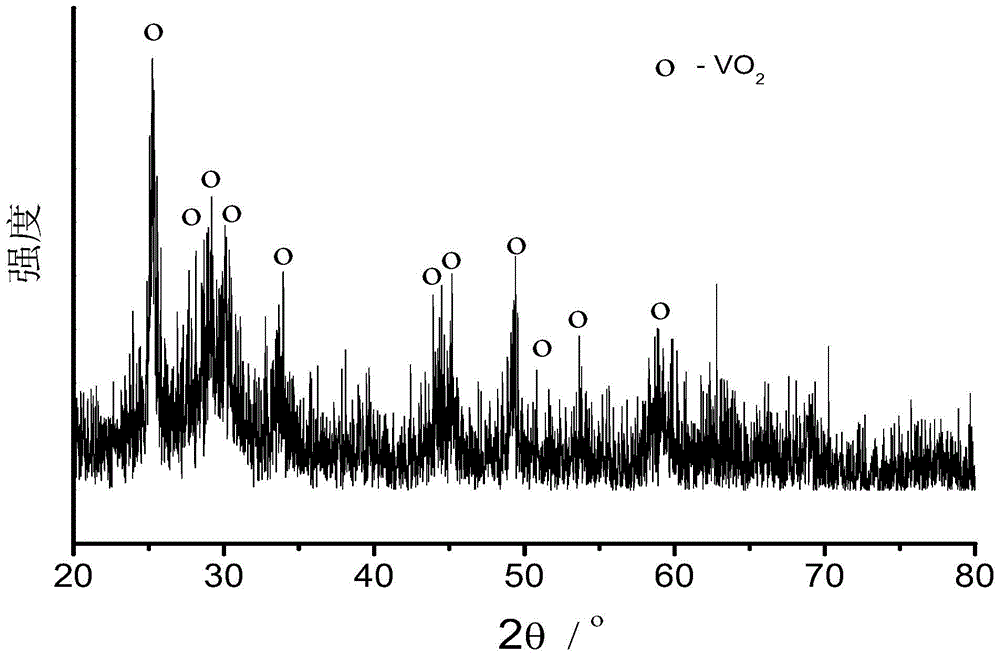

[0060] Purge the tube furnace with hydrogen for 5 minutes, check the gas connection of the system, then put 10g of ammonium polyvanadate into the quartz boat, and send it to the middle of the tube furnace, close the furnace door, and set the hydrogen flow rate to 300mL / min, start the program to heat up to 400°C, stop heating after 120min of heat preservation, keep the hydrogen flowing in during the natural cooling process, open the furnace door and take out the quartz boat when the temperature drops to room temperature, the obtained dark blue sample is VO 2 , the yield was 99.7%.

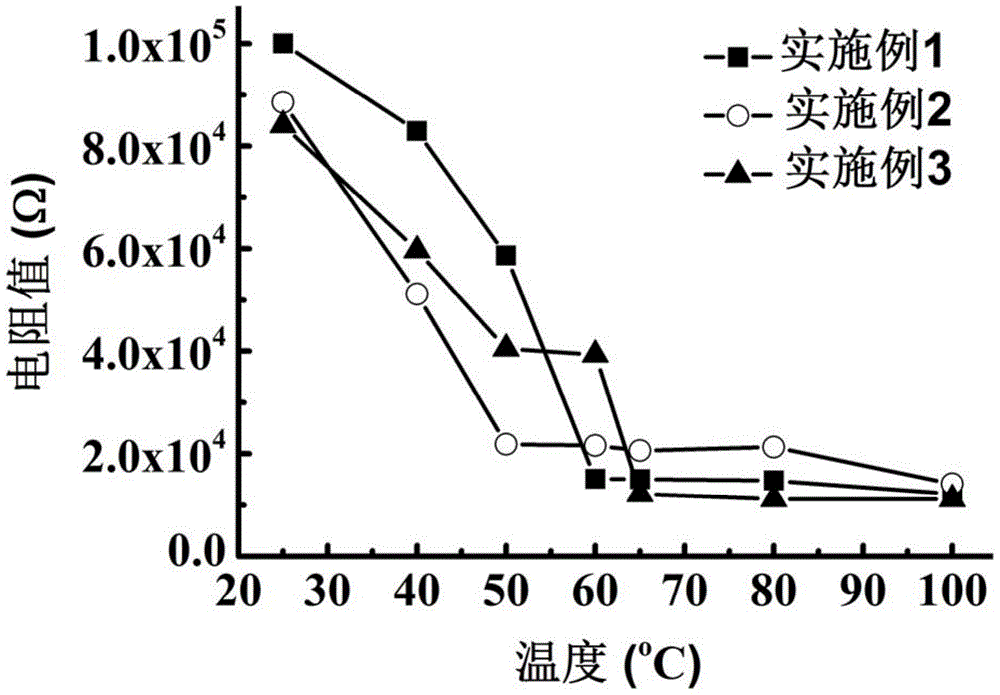

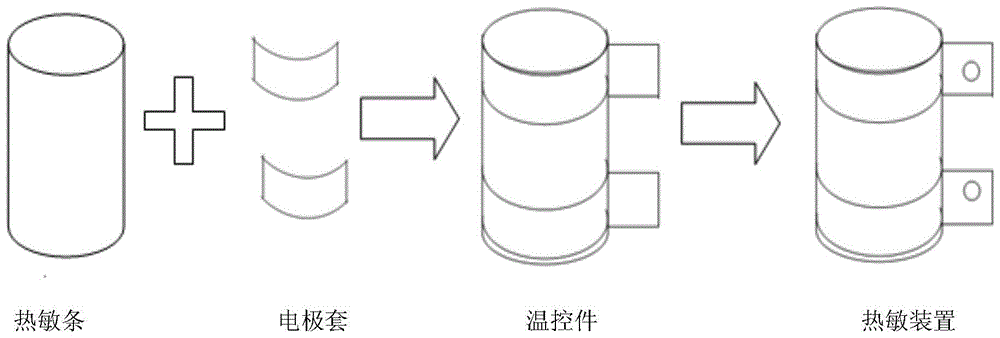

[0061] The obtained VO prepared in this embodiment 2 The temperature control is press-molded into a rod with a diameter of 10mm and a height of 30mm, and the pressure is 15MPa. The aluminum sheet is used as the electrode sleeve, and the distance between the positive and negative conductive sheets is VO 2 1.5 times the diameter of the temperature control. After testing the sample resistance at di...

Embodiment 2

[0063] Purge the tube furnace with hydrogen for 10 minutes, check the gas connection of the system, then put 15g of ammonium polyvanadate into the quartz boat, and send it to the middle of the tube furnace, close the furnace door, and set the hydrogen flow rate to 320mL / min, start the program to heat up to 350°C, stop heating after 60min of heat preservation, keep hydrogen flowing in the process of natural cooling, open the furnace door and take out the quartz boat when the temperature drops to room temperature, the obtained dark blue sample is VO 2 , the yield was 99.5%.

[0064] The obtained VO prepared in this embodiment 2 The temperature control is press-molded into a rod with a diameter of 20mm and a height of 40mm, and the pressure is 20MPa. The aluminum sheet is used as the electrode sleeve, and the distance between the positive and negative conductive sheets is VO 2 Twice the diameter of the temperature control. After testing the sample resistance at different temp...

Embodiment 3

[0066] Purge the tube furnace with hydrogen for 5 minutes, check the gas connection of the system, then put 10g of ammonium polyvanadate into the quartz boat, and send it to the middle of the tube furnace, close the furnace door, and set the hydrogen flow rate to 300mL / min, start the program to heat up to 450°C, stop heating after 50min of heat preservation, keep the hydrogen flowing in during the natural cooling process, open the furnace door and take out the quartz boat when the temperature drops to room temperature, the obtained dark blue sample is VO 2 , the yield was 99.5%.

[0067] The obtained VO prepared in this embodiment 2 The temperature control is press-molded into a rod with a diameter of 20mm and a height of 30mm, and the pressure is 25MPa. The copper sheet is used as the electrode sleeve, and the distance between the positive and negative conductive sheets is 2.2 times the diameter of the VO2 temperature control. After testing the sample resistance at differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com