Anti-plugging demister

A mist eliminator and anti-clogging technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., to achieve the effects of preventing blade scaling and clogging, good flushing ability, and enhanced trapping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

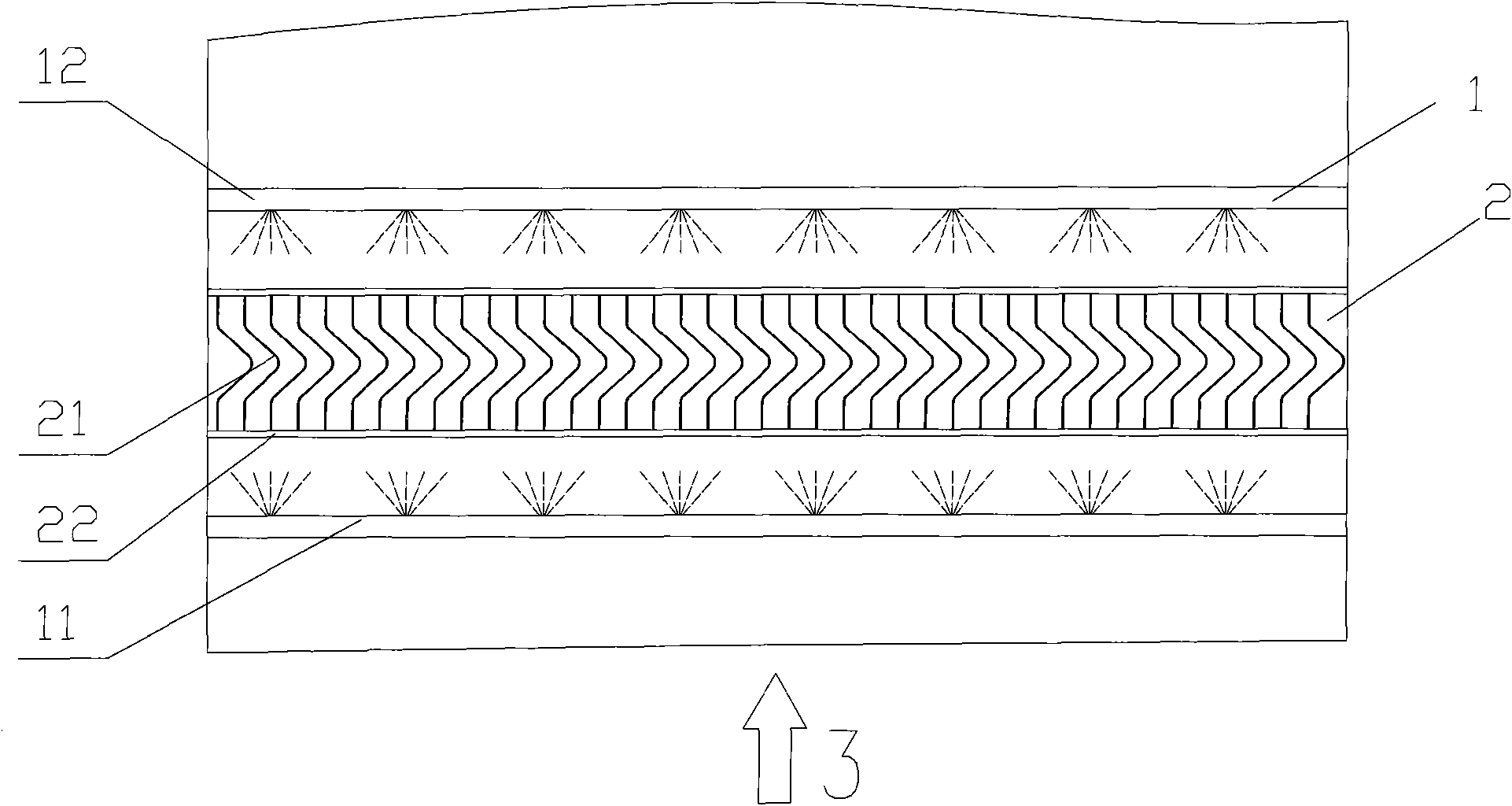

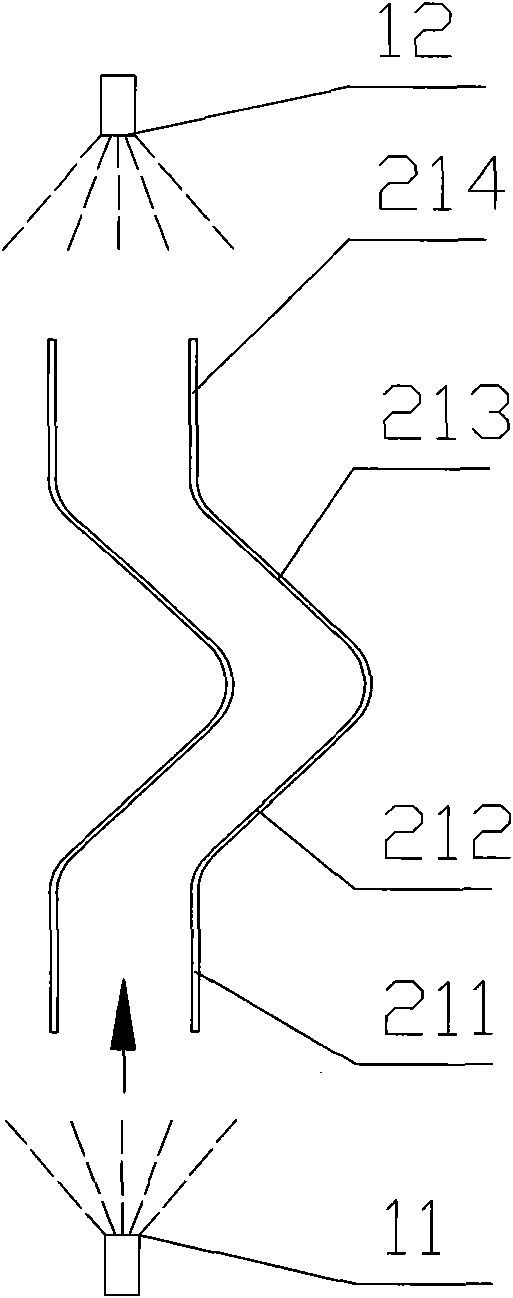

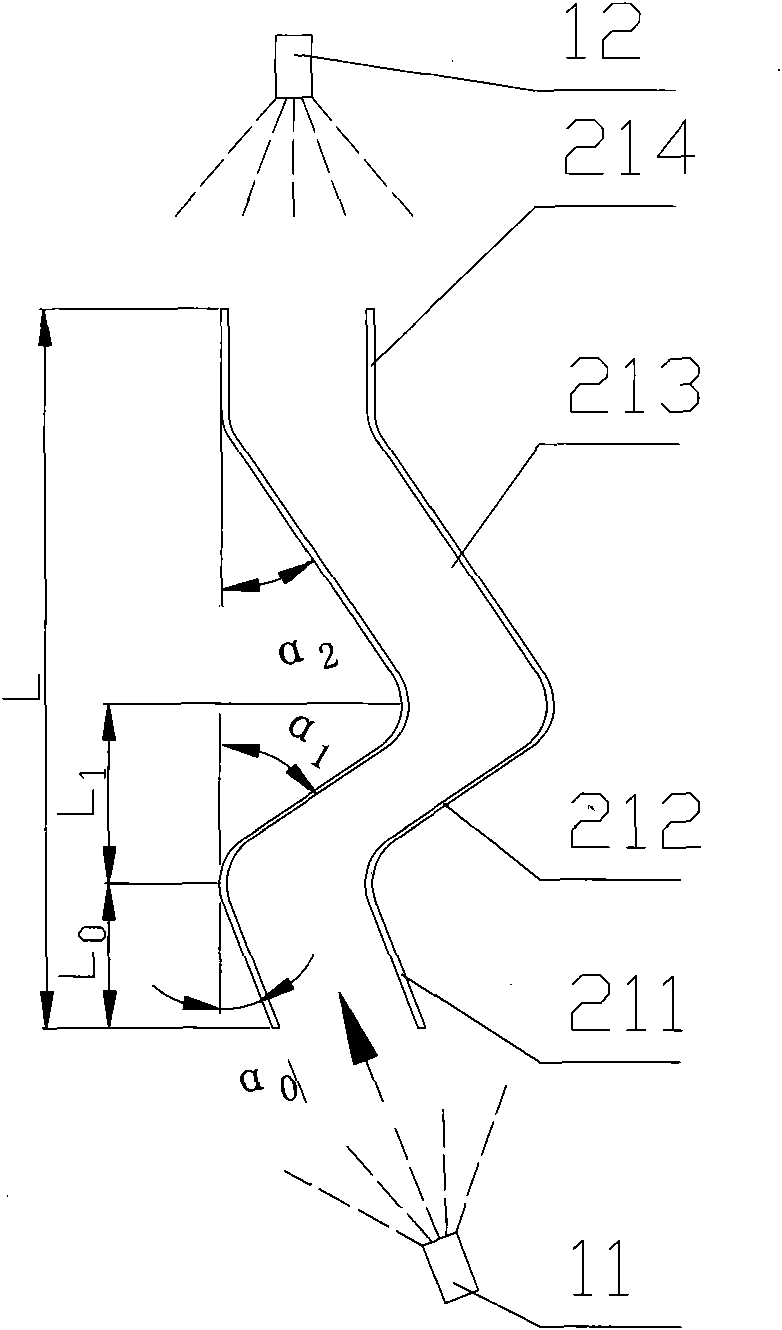

[0020] The overall structural type of the mist eliminator of the present invention is the same as that of the traditional mist eliminator, including the flushing device 1 and the mist eliminator body 2 - the mist eliminator blades 21 and the mist eliminator frame 22 . However, in order to realize the anti-clogging function, the present invention uses CFD simulation and test means to specially design the demister blades 22 . The blades of the traditional mist eliminator have a symmetrical structure, but the present invention adjusts the geometric dimensions of the blades according to the actual working environment of the mist eliminator. Specifically, the geometric shape of the mist eliminator blades of the present invention has three changes in total, which can be compared figure 2 , image 3 :

[0021] 1. Change the structure of the traditional demister blade inlet section 211 and the flue gas flow to form a certain angle α between the inlet section (or introduction sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com