TF unit combination sewage treatment technology

A treatment process and sewage treatment technology, applied in the direction of biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and high operating costs, etc., to achieve the effect of strong impact load capacity, flexible process combination, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

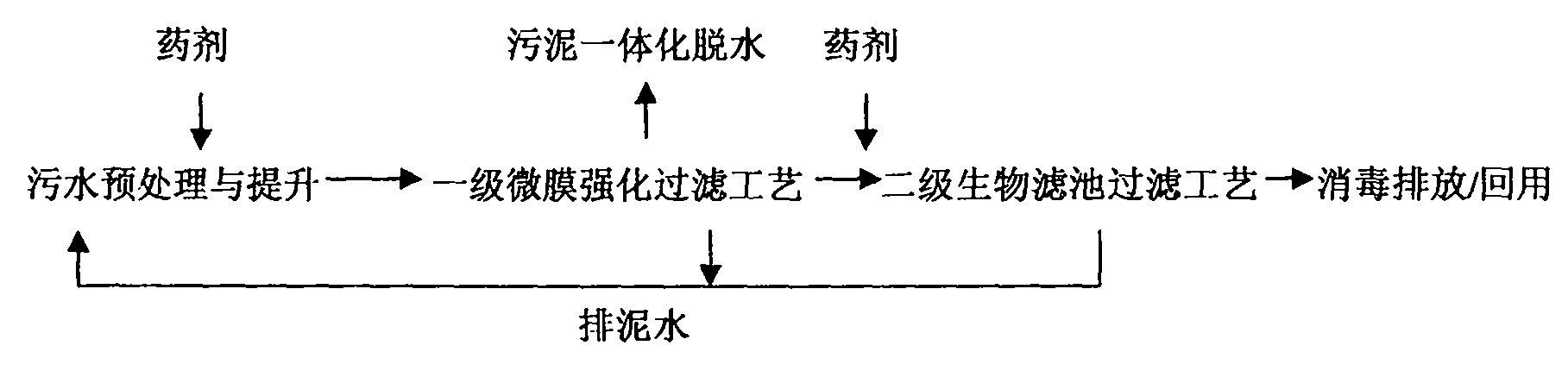

[0016] The core of this embodiment is to adopt a treatment process in which the first-stage micro-membrane enhanced filtration and the second-stage biological filter are combined. The schematic diagram of the implementation of the case release process is shown in figure 1 :

[0017] Among them, you can choose not to add the front-end of the first-stage micro-membrane enhanced filtration process and the front-end of the second-stage biochemical filtration, and add metal aluminum salt agents, iron salts, and polymer agents separately or separately.

[0018] The one-stage micro-membrane enhanced filtration process can remove 60%-80% of suspended solids, 40-50% of COD, and BOD 5 20-40%, and the removal rate of total phosphorus reaches more than 20-90%. At the same time, the micro-membrane filter also replaces the traditional sludge dewatering machine, directly dehydrates the generated sludge, realizes the integrated treatment of sewage and sludge, and saves the process of grit c...

specific Embodiment approach 2

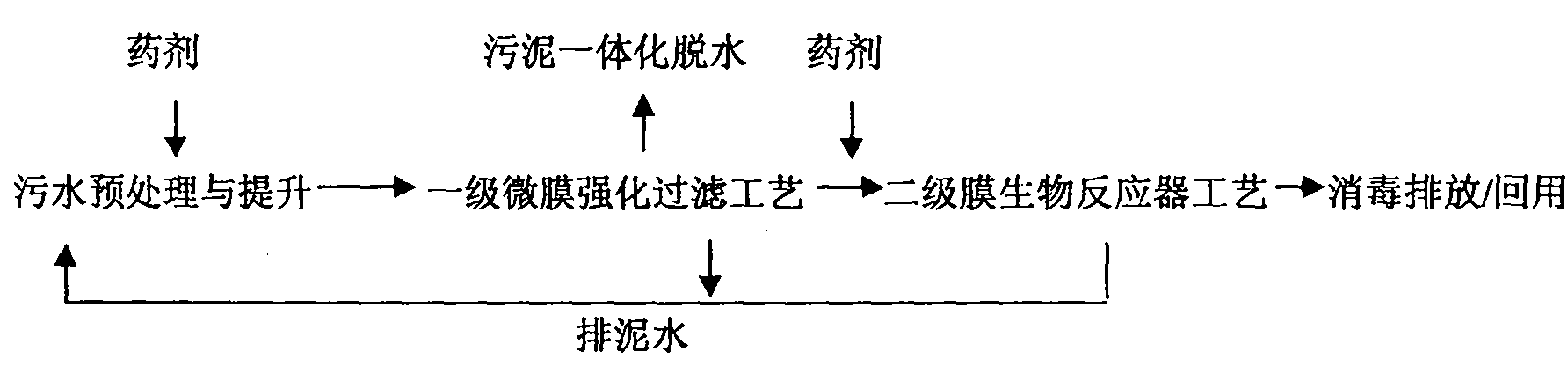

[0023] The core of this embodiment is to use a treatment process that combines the first-stage micro-membrane enhanced filtration with the second-stage membrane bioreactor filtration. The schematic diagram of the process flow of this implementation scheme is shown in figure 2 :

[0024] Among them, you can choose not to add the front-end of the first-stage micro-membrane enhanced filtration process and the front-end of the second-stage biochemical filtration, and add metal aluminum salt agents, iron salts, and polymer agents separately or separately.

[0025] The one-stage micro-membrane enhanced filtration process can remove 60%-80% of suspended solids, 40-50% of COD, and BOD 5 20-40%, and the removal rate of total phosphorus reaches more than 20-90%. At the same time, the micro-membrane filter also replaces the traditional sludge dewatering machine, directly dehydrates the generated sludge, realizes the integrated treatment of sewage and sludge, and saves the process of g...

specific Embodiment approach 3

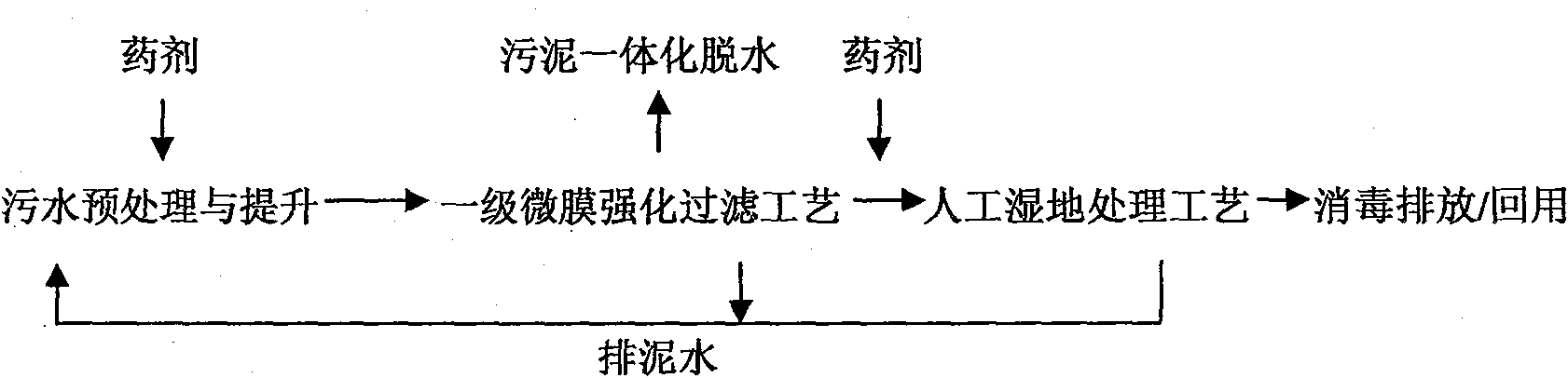

[0030] The core of this implementation plan is the use of a treatment process that combines the first-level micro-membrane enhanced filtration with the second-level constructed wetland treatment. The schematic diagram of the implementation of the case release process is shown in image 3 :

[0031] Among them, you can choose not to add the front-end of the first-stage micro-membrane enhanced filtration process and the front-end of the second-stage biochemical filtration, and add metal aluminum salt agents, iron salts, and polymer agents separately or separately.

[0032] The one-stage micro-membrane enhanced filtration process can remove 60%-80% of suspended solids, 40-50% of COD, and BOD 5 20-40%, and the removal rate of total phosphorus reaches more than 20-90%. At the same time, the micro-membrane filter also replaces the traditional sludge dewatering machine, directly dehydrates the generated sludge, realizes the integrated treatment of sewage and sludge, and saves the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com