Double-layer concentration table

A double-layer and lower-layer technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of small mineral processing capacity of a single equipment, huge construction of mineral processing plants, and large installation area. The effect of halving the amount of equipment foundation works, reducing the operating range and reducing the amount of construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

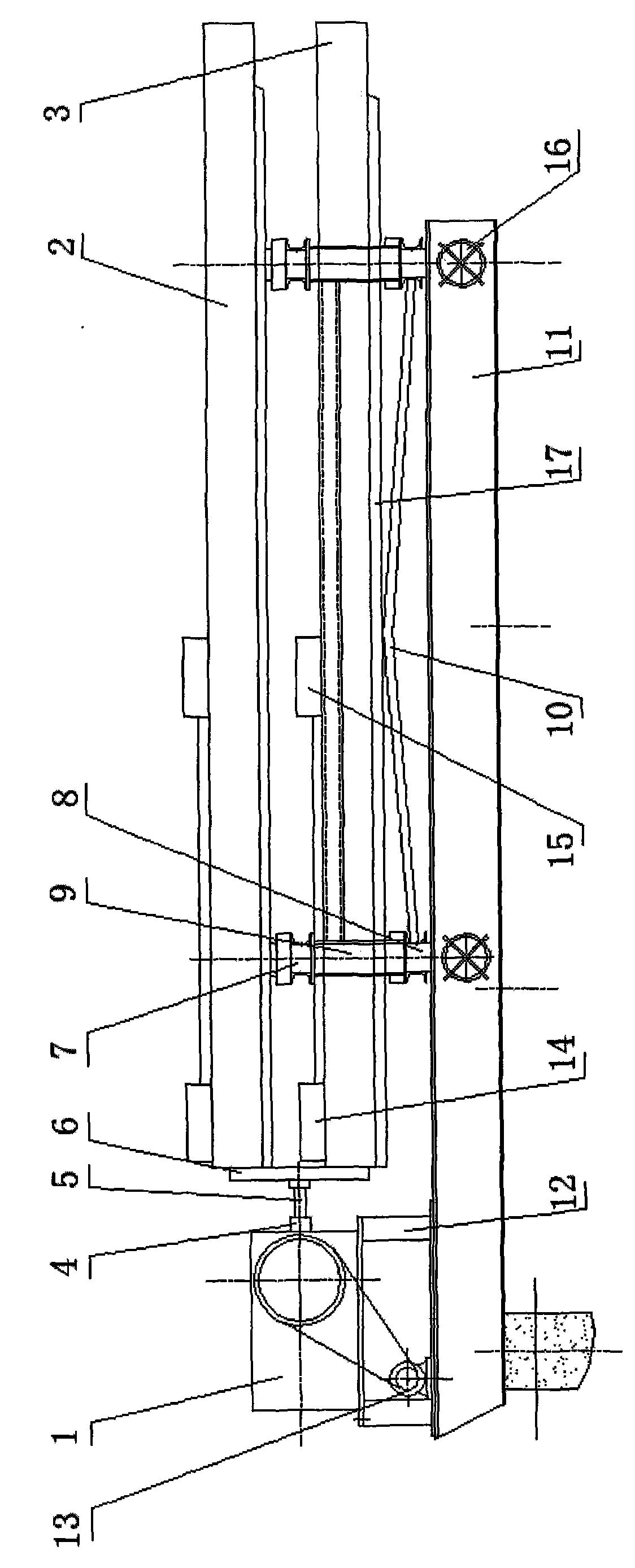

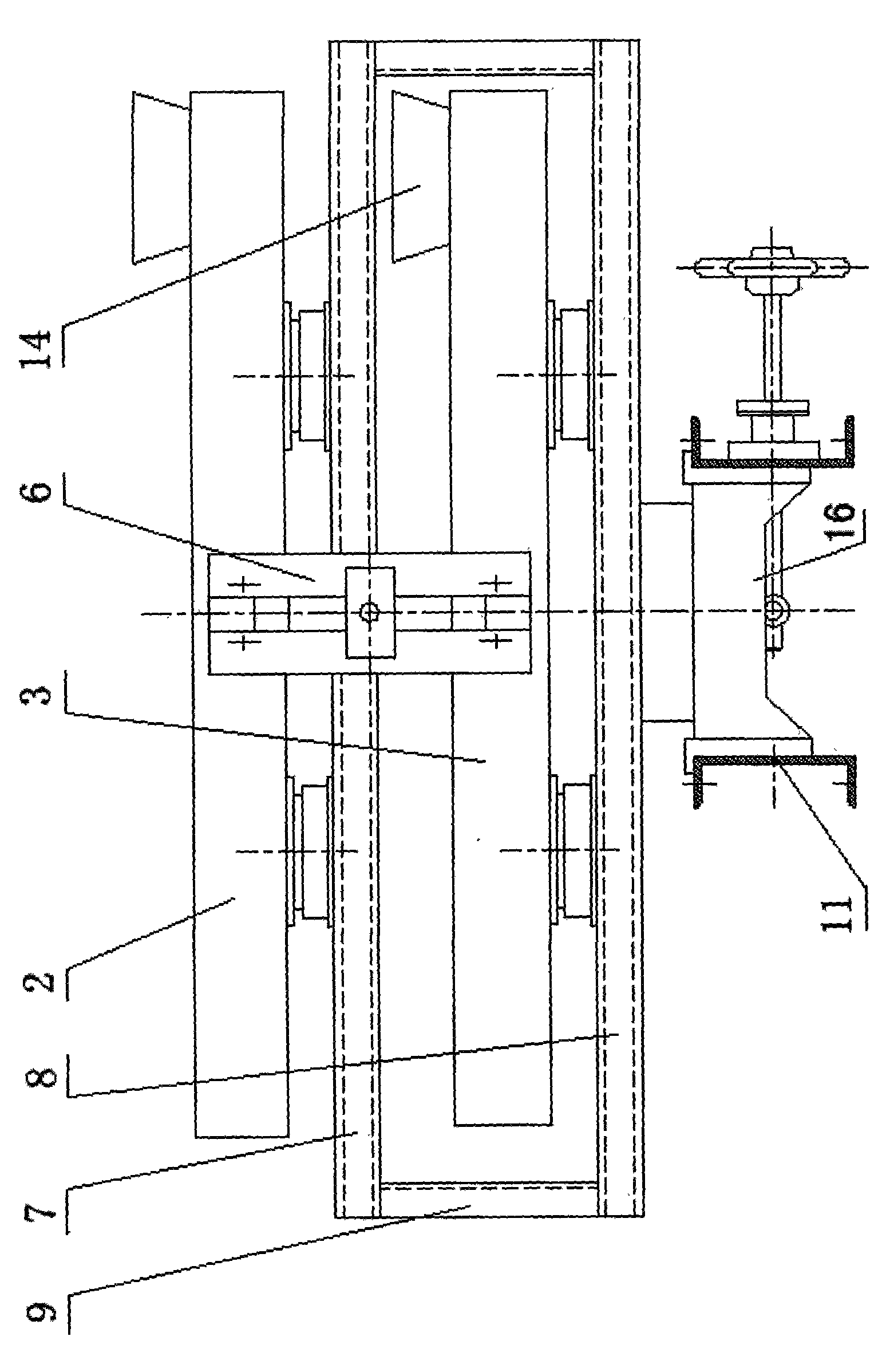

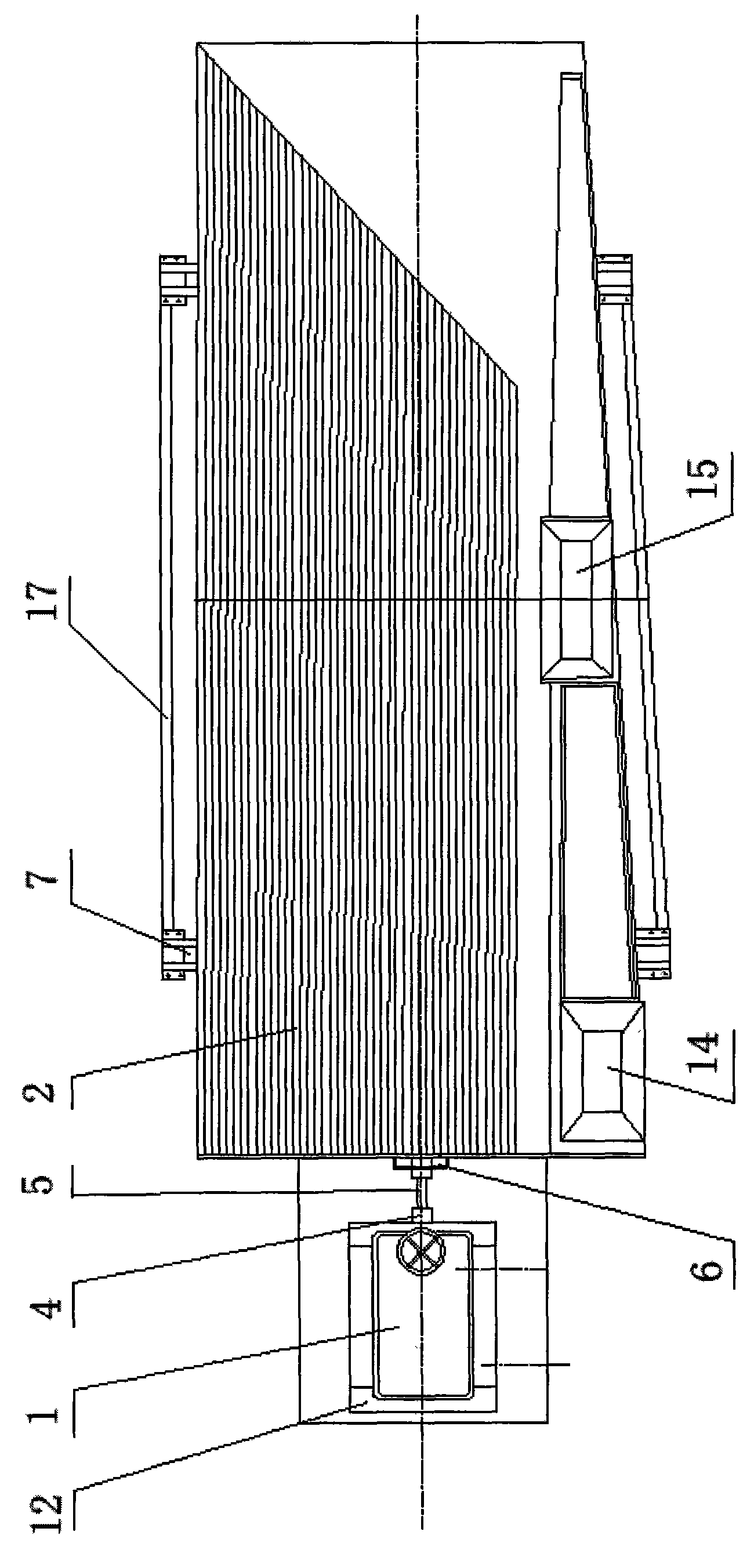

[0015] The transmission box 1 is placed on the transmission box support seat 12 at the end of the frame 11, the lower support clamping frame 8 of the double bed surface frame is placed on the saddle seat 16 of the slope adjustment mechanism, the upper shaker surface 2 and the lower shaker The surface 3 is respectively placed on the upper layer support clamping frame 7 and the lower layer support clamping frame 8 of the double-layer bed surface frame through the shaking support mechanism, and the end surfaces of the upper layer shaking table surface 2 and the lower layer shaking table surface 3 use the bed surface linkage plate 6 Connect, the two ends of the connecting screw rod 5 are hard connected with the transmission box linkage seat 4 and the bed surface linkage plate 6 respectively.

[0016] The frame 11 of the shaking table: on two parallel large channel steels, connect the transmission box supporting seat 12 and the saddle seat 16 of the slope adjustment mechanism succes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com