Tangential telescopic ultrasonic torsional transducer

An ultrasonic and transducer technology, applied in the field of tangentially telescopic ultrasonic torsional vibration transducers, can solve the problems of low power and amplitude, complex structure, small power and output amplitude of torsional transducers, etc. And the effect of easy bonding, simple driving method and less energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings.

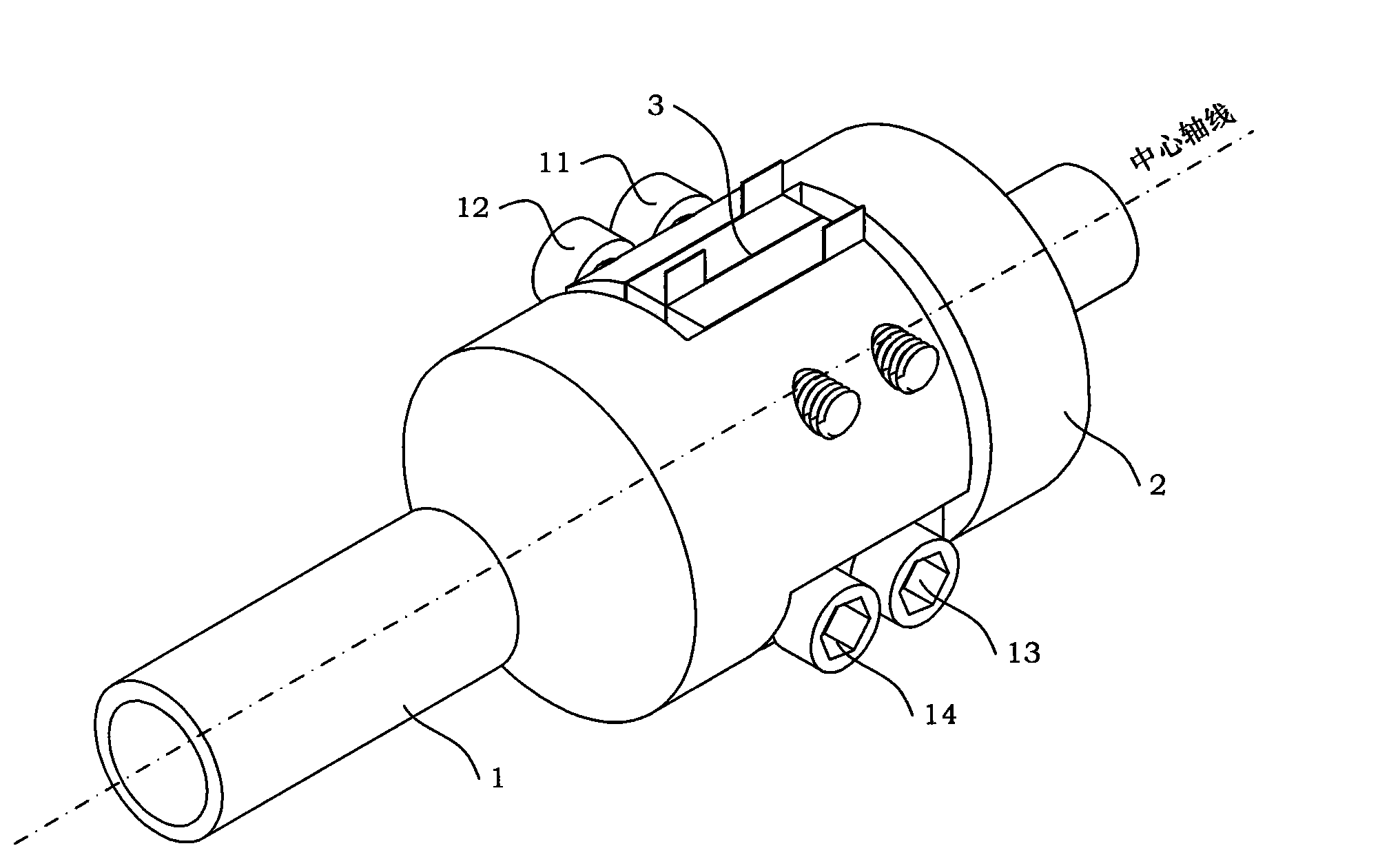

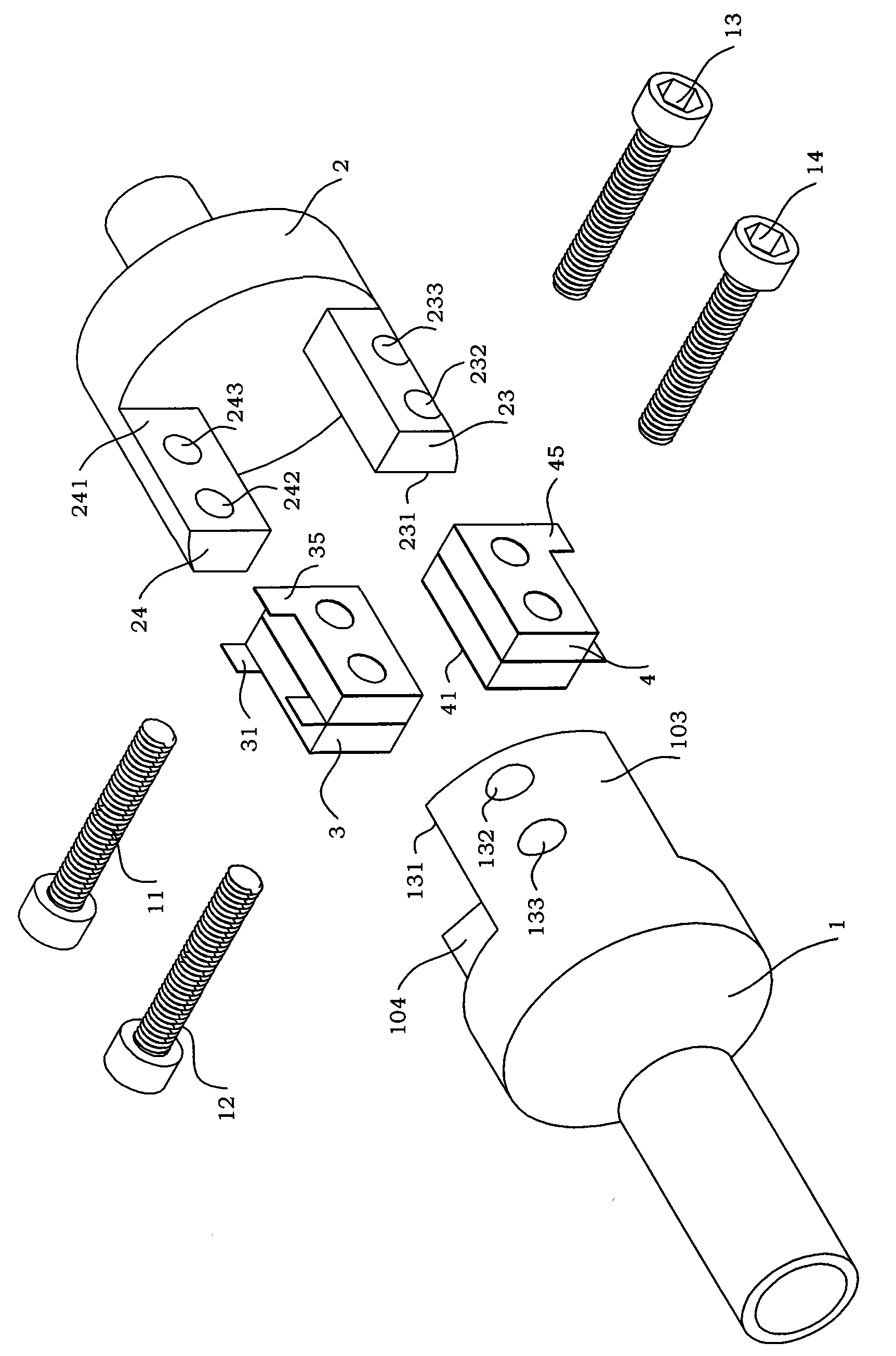

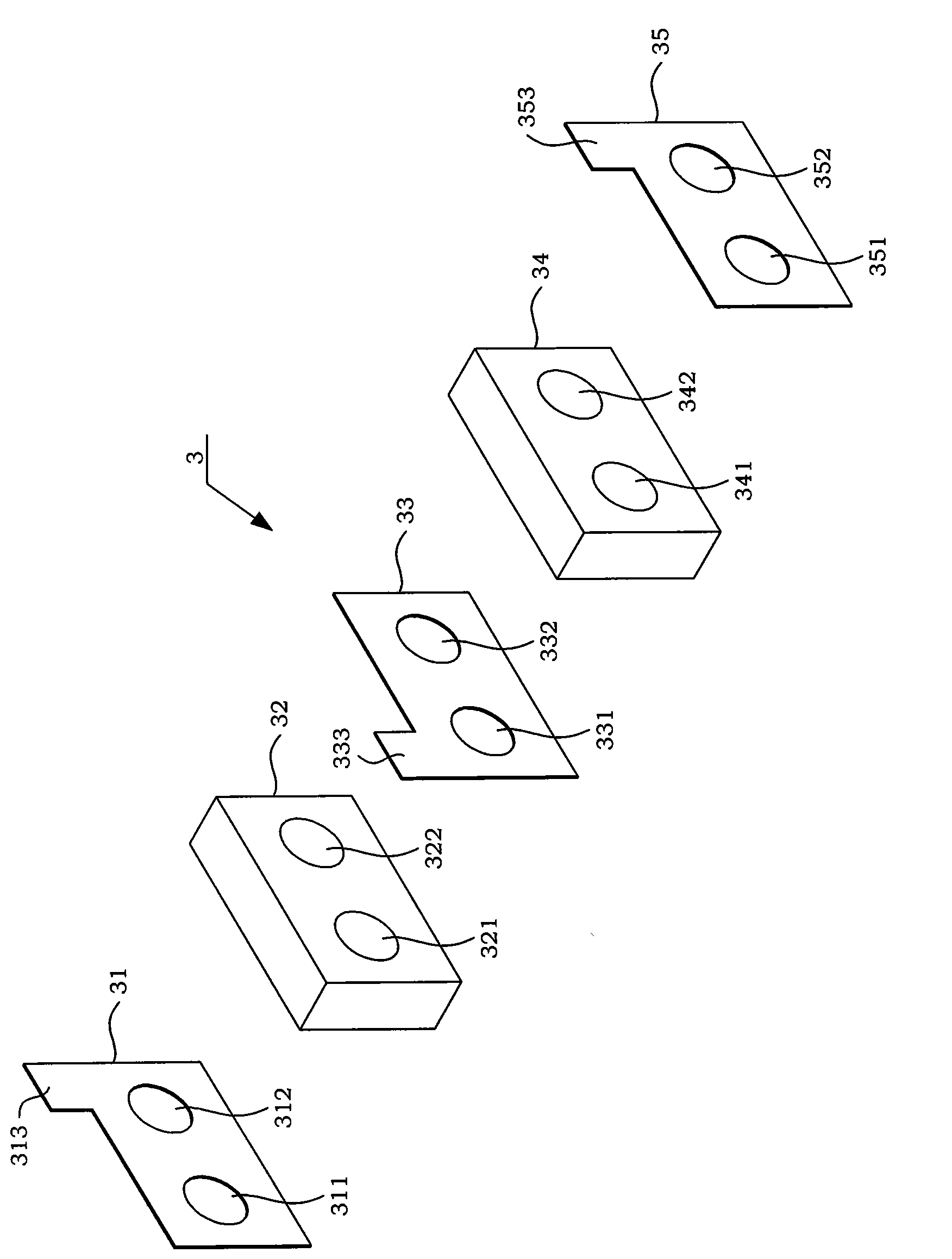

[0044] A tangential telescopic ultrasonic torsional transducer of the present invention includes a front cover body 1, a rear cover body 2, an A drive assembly 3, a B drive assembly 4 and four long screws (A long screw 11, B long screw 12, C long screw 13, D long screw 14), the structure of A driving assembly 3 and B driving assembly 4 is identical.

[0045] 1. Front cover 1

[0046] see Figure 4 , Figure 4A , Figure 4B As shown, the front cover 1 is integrally formed and processed. The front cover 1 is divided into a horn 101 , a cylindrical seat 102 , an A connecting arm 103 and a B connecting arm 104 according to the functions realized.

[0047] The contact surface 131 of the A connecting arm 103 is provided with an A threaded hole 132 and a B threaded hole 133 , and the A threaded hole 132 and the B threaded hole 133 penetrate the contact surface 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com