Method for realizing high-speed following ink-jet printing by dynamically controlling print resolution

An inkjet printing and dynamic control technology, applied in printing and other directions, can solve problems such as image distortion, pattern distortion, and paper movement speed limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

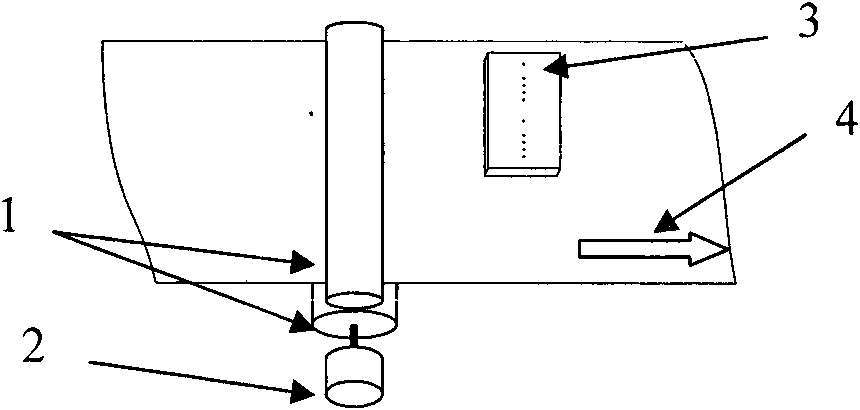

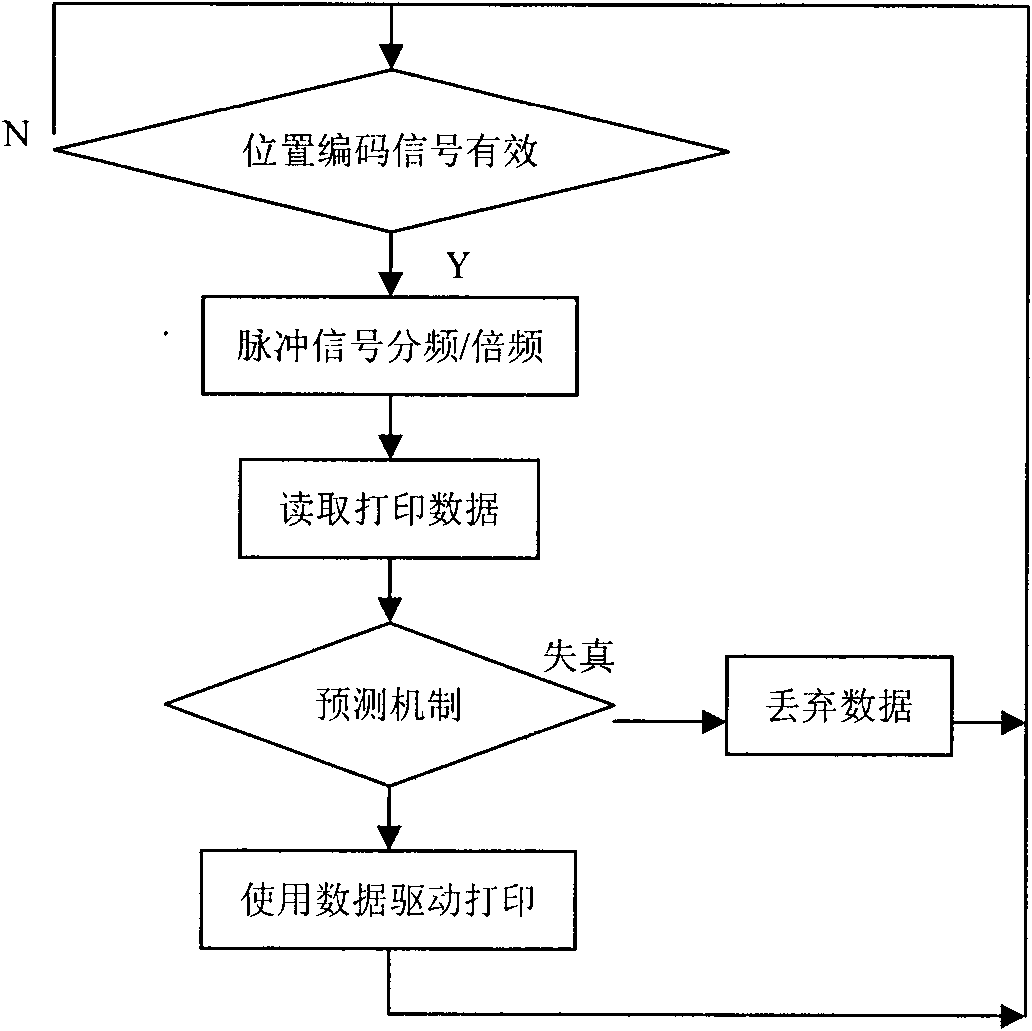

[0027] refer to Figure 1 ~ Figure 3 , a method for realizing high-speed follow-up inkjet printing by dynamically controlling printing resolution, said method comprising the following steps:

[0028] (1), collect the position pulse signal on the position encoder, control the ignition pulse signal of the printing head according to the position pulse signal;

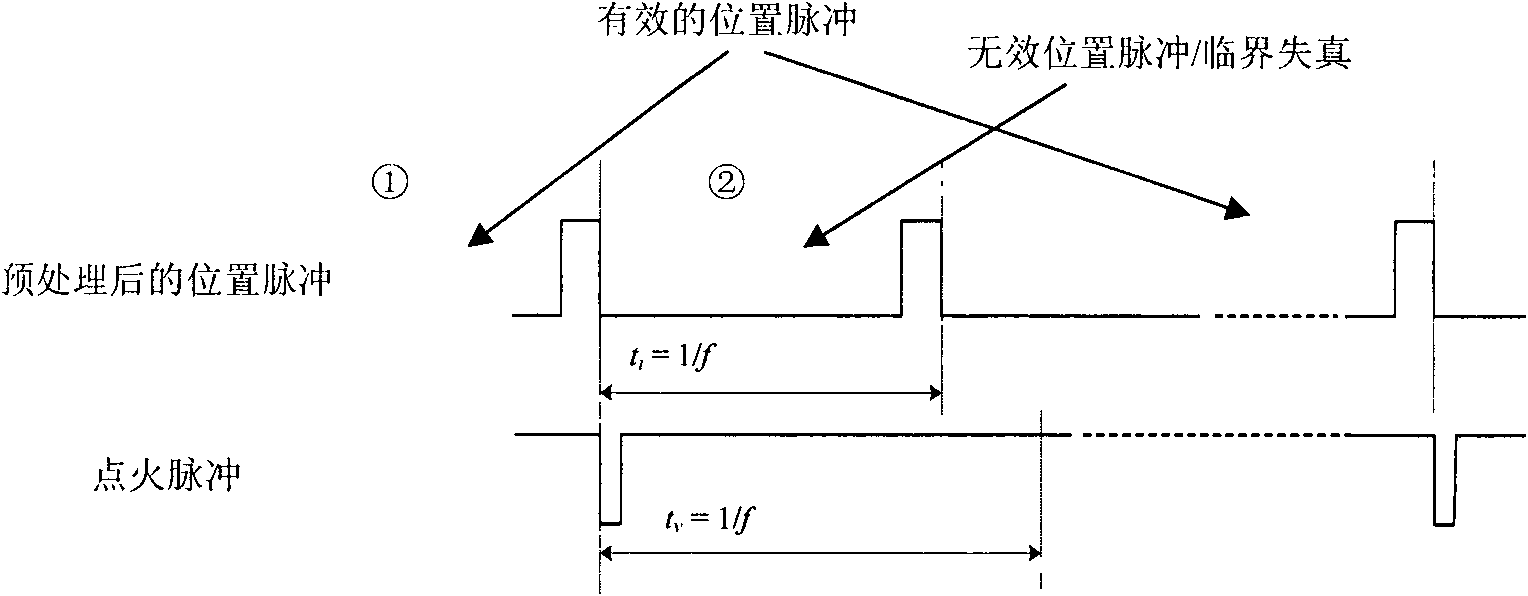

[0029] (2), set the time between the next position pulse signal and the adjacent previous position pulse signal as t i ;The maximum firing frequency of the print head is f,t v = 1 / f; when t i v , it is determined that there is a risk of distortion, the latter position pulse signal is an invalid pulse signal, and the latter position pulse signal is discarded.

[0030] In this embodiment, the method for predicting the imminent printing geometric distortion: a prediction mechanism is designed to detect the critical moment when the printing geometric distortion is imminent.

[0031] The reason for the geometric distortion ...

Embodiment 2

[0038] In this embodiment, a window mechanism for reducing resolution is also designed to suppress the phenomenon of resolution jitter.

[0039] Due to the mechanical mechanism, there is often a narrow-band oscillation phenomenon with a fixed frequency in the relative motion speed. When the relative motion speed is at the critical value (v m ) around , this oscillation causes the distortion prediction mechanism to produce valid output periodically. The result is a noticeable periodic dithering of the print resolution over a small range.

[0040] A window mechanism with reduced resolution is introduced, and the window width Wd is based on the number of pulse signals output by the position encoder. It is stipulated that once the risk of distortion is predicted, it shall be handled according to the following steps:

[0041] e, actively reduce the resolution to 1 / 2 of the original value

[0042] f, unconditionally keep this lower resolution at least Wd

[0043] g, within this r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com