Alloy tool steel and manufacturing method thereof

A tool steel, controlled technology, applied in the field of tool steel, can solve problems such as increased cutting tool load, cutting tool breakage, no countermeasures found

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

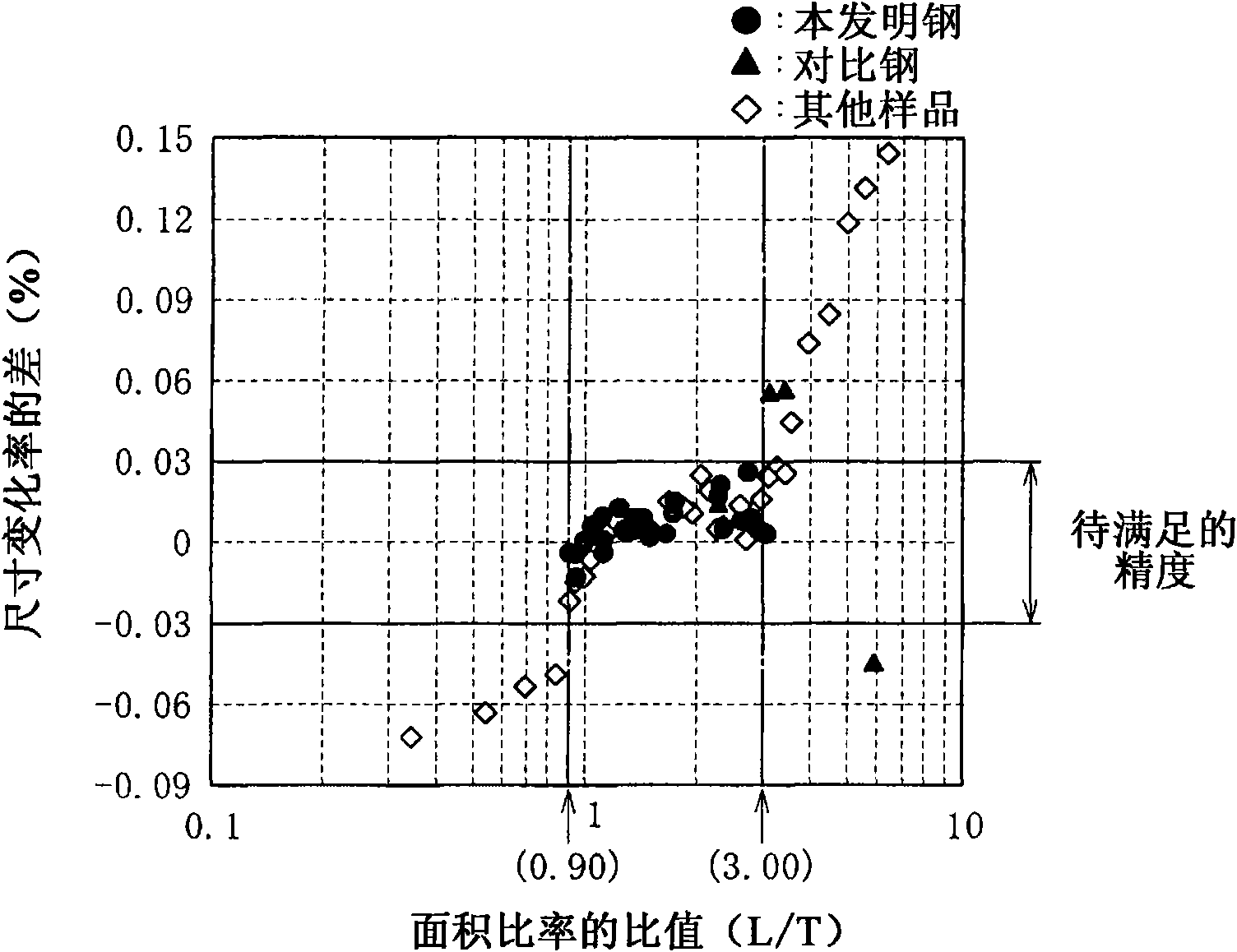

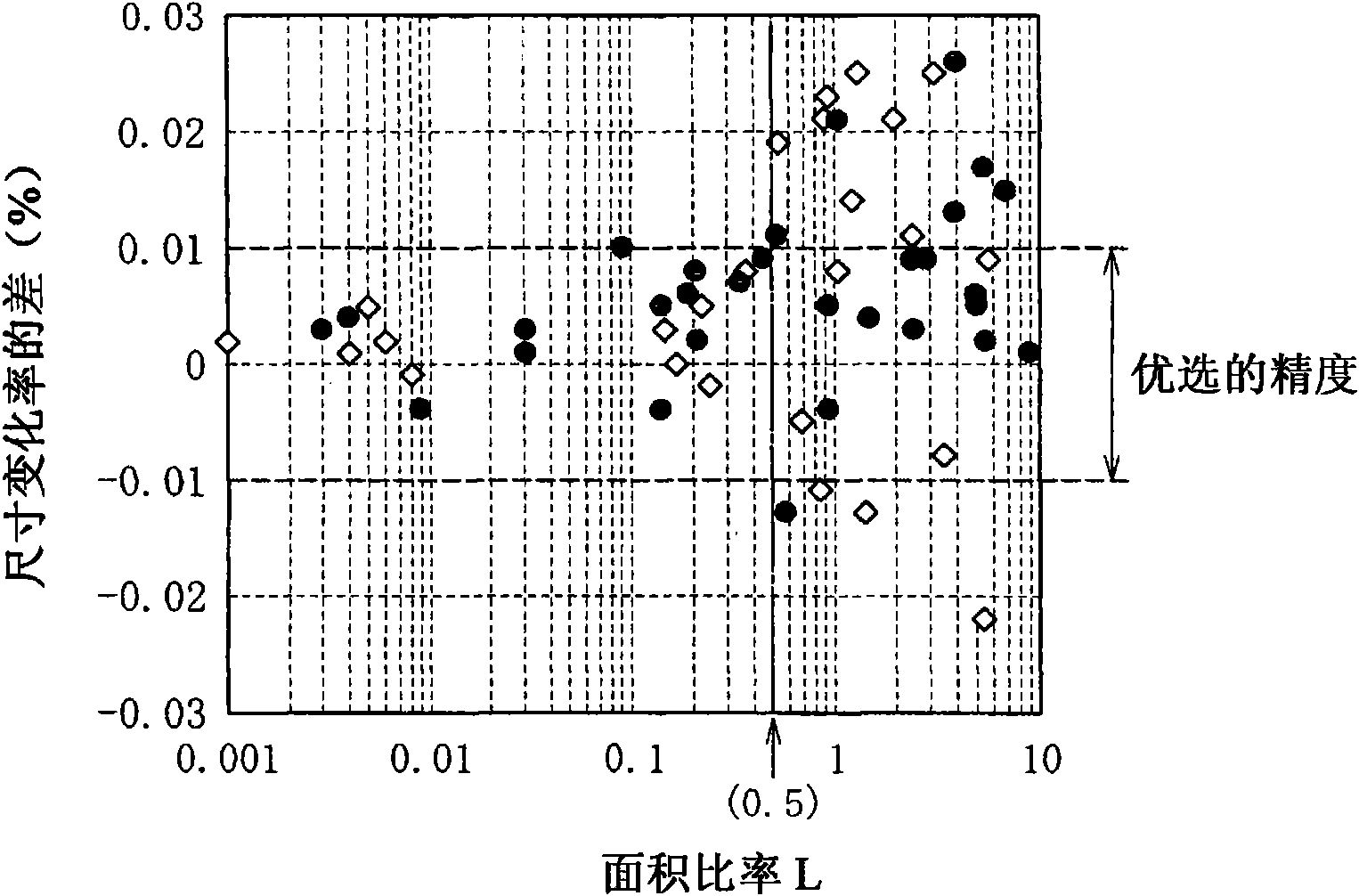

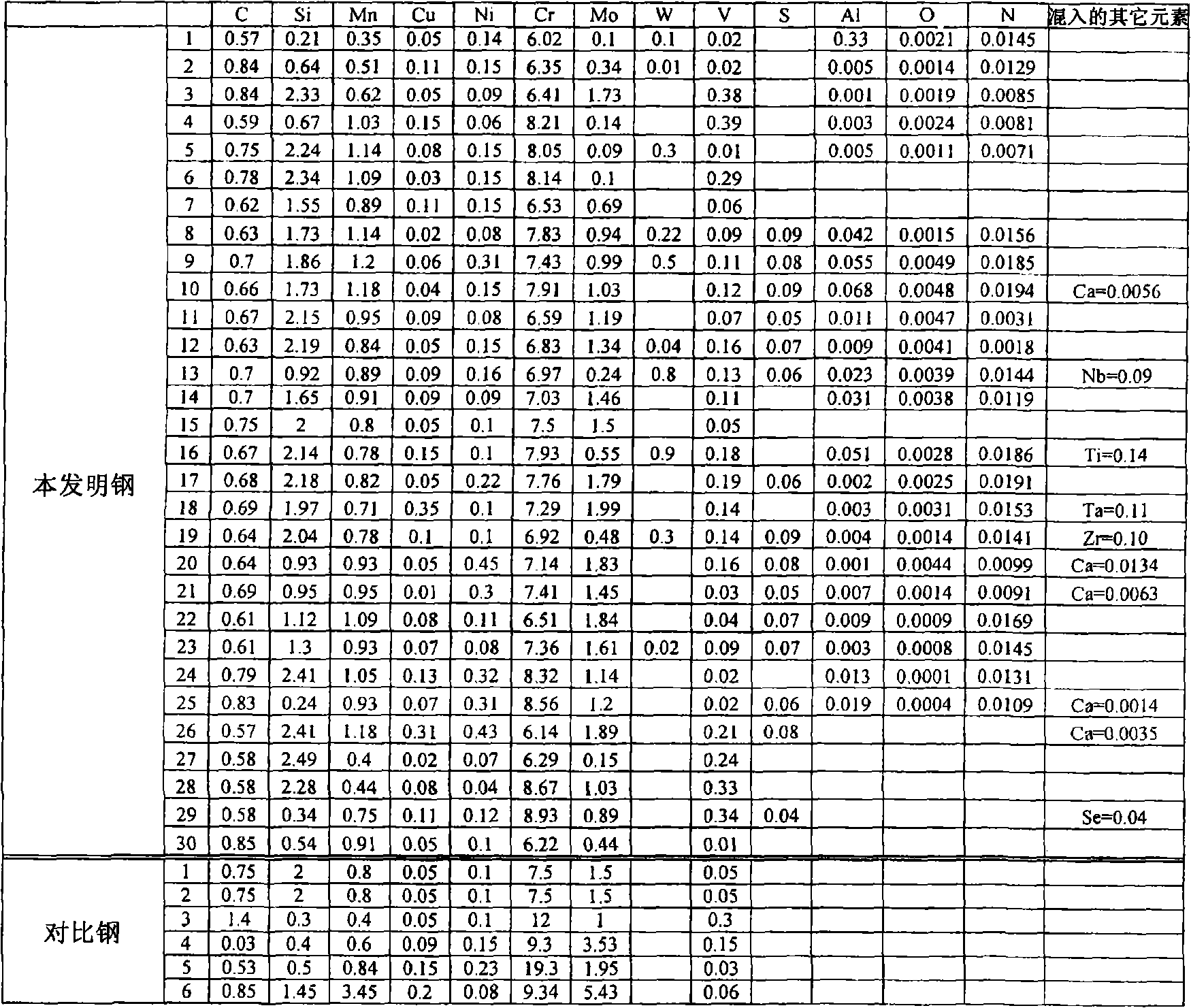

[0050] The inventors of the present invention focused on the study of the distribution state of carbides in the process of solving the phenomenon of anisotropic and non-uniform expansion of tool steel due to quenching and tempering, and studied the distribution state of carbides It is found that there is a close relationship between the distribution state of carbides and the expansion of tool steel.

[0051]More specifically, based on the fact that after quenching and tempering, tool steel expands largely in the direction of forging and expands less in the direction perpendicular to the direction of forging, the present inventors have studied The distribution state in the cross section of the forging direction and the distribution state of carbides in the cross section perpendicular to the forging direction. As a result of studies, the present inventors found that, in a cross section parallel to the forging direction, coarse carbides having an equivalent circle diameter of 2 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com