Gas-liquid mixing pump

A gas-liquid mixing pump and pump body technology, which is applied in the direction of pumps, rotary piston pumps, liquid fuel engines, etc., can solve the problems of high cost and short rotor life, and achieve the effects of improving efficiency, eliminating pulsation, and smooth thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

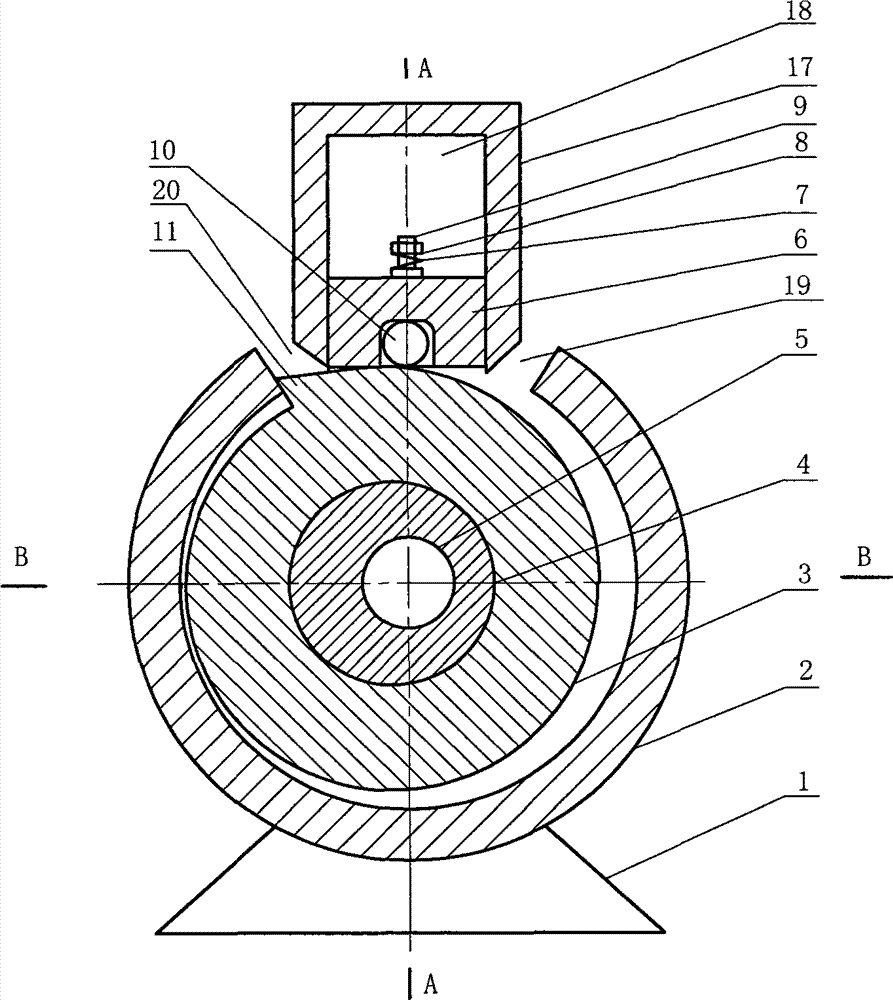

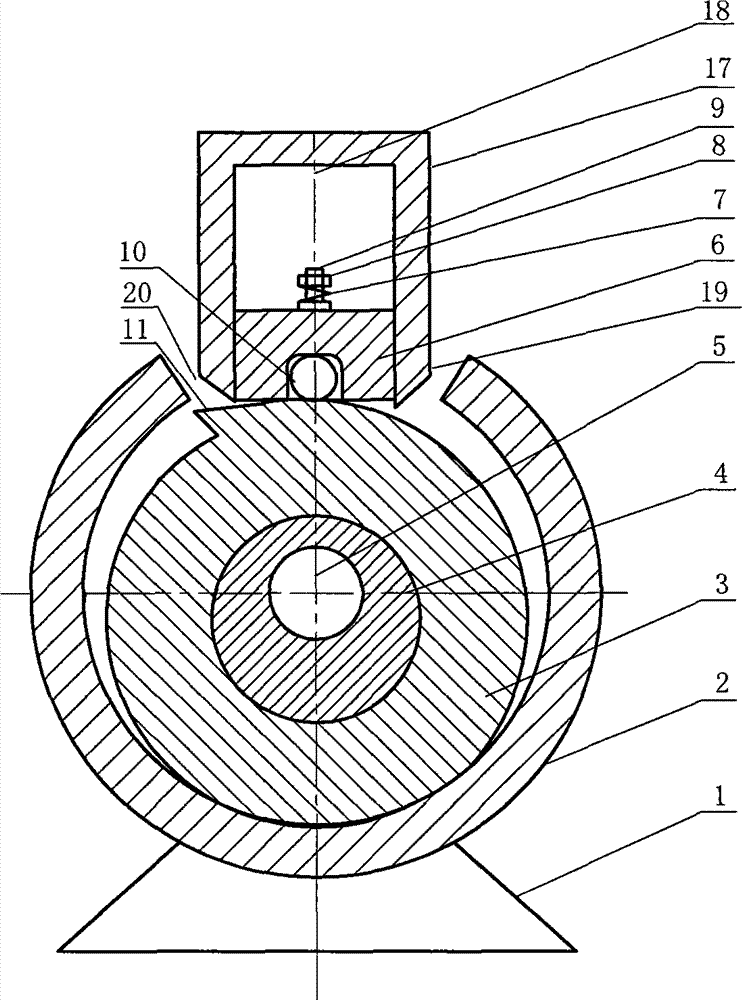

[0020] Such as figure 1 As shown, a gas-liquid mixing pump of the present invention includes: a pump casing, a machine base 1, a rotor and an end cover 13, the pump casing is composed of a cylindrical pump body 2 and a joint 17 connected to it above it, and 2n rotors are installed In the 2n inner cavities of the cylindrical pump body 2, n is an integer greater than or equal to 1, which is selected from any one of integers 1 to 10. 2n rotors are mounted on the same straight main shaft 5, and the phase difference between adjacent rotors is 360° divided by 2n. There is a cavity 18 in the joint 17, the cavity 18 is equipped with a pressure plate 6, the pressure plate 6 moves along the cavity 18, one end of the pressure plate 2 is always in contact with the rotor, the upper central part of the cylindrical pump body 2 has a hole, the pressure plate 6 will The hole is separated into a liquid inlet 19 and a liquid outlet 20 .

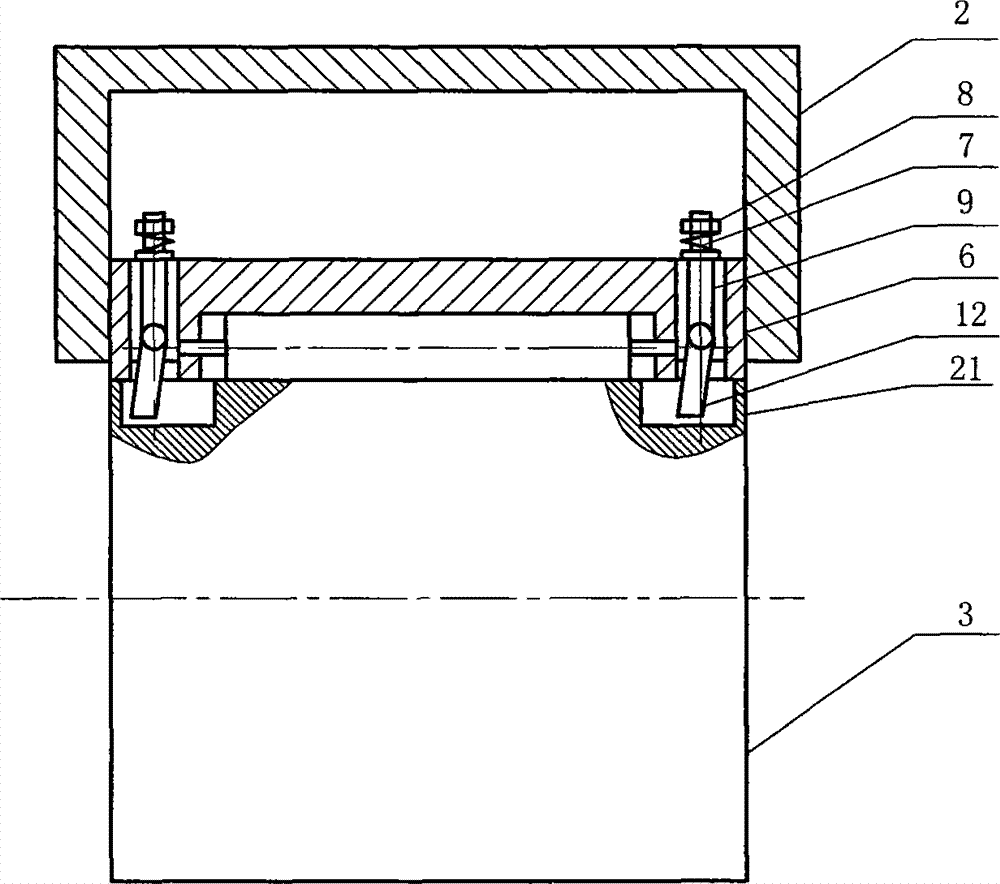

[0021] Such as figure 2 with image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com