Method for detecting synchronous vibration parameters of high-speed rotary blade under constant speed

A technology of synchronous vibration and high-speed rotation, which is applied in the direction of vibration measurement in solids, measuring vibration, measuring devices, etc., to achieve real-time online monitoring and simplify the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

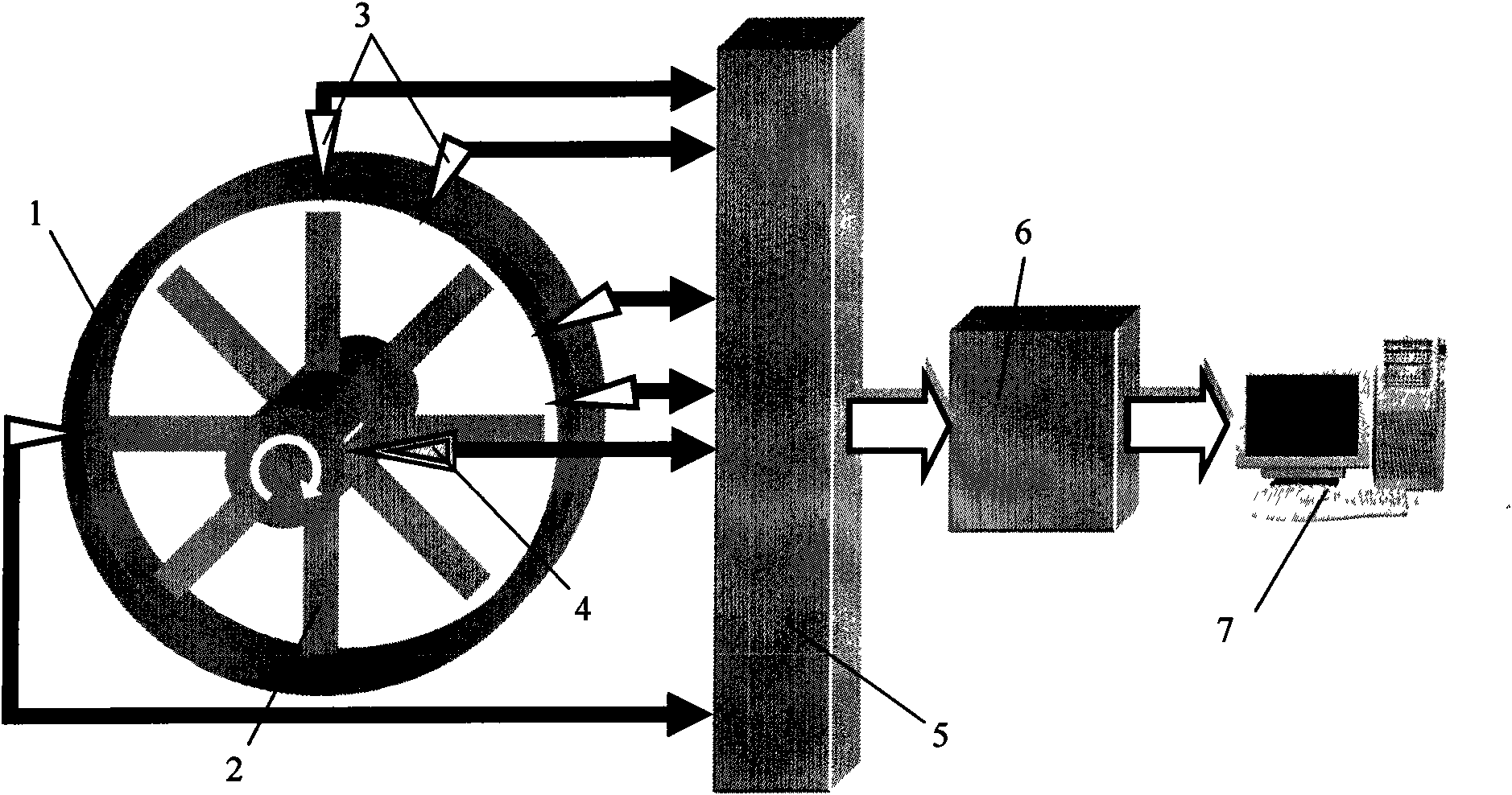

[0023] exist figure 1 In the above, the rotating machinery rotor blade 2 runs at a relatively constant speed, and the signals measured by the blade tip timing sensor 3 and the speed synchronization sensor 4 pass through the processing module 5 and the acquisition module 6 to extract the vibration information of all blades when they pass through the synchronous resonance zone. After adopting various processing algorithms in the computer 7, the vibration parameters such as the natural frequency fn of the synchronous vibration of the blade, the vibration displacement y, the amplitude A, and the double frequency Ne are accurately identified.

[0024] When the rotating machine is running at a certain constant speed, if a blade synchronously vibrates at double frequency Ne at this speed, the synchronous vibration displacement y of a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com