System and method for metering cooling/heating amount of air conditioners

A heat metering and air conditioning technology, which is applied to the cooling/heat metering system and cooling/heat metering field of fan coil air conditioners, can solve the problems of complicated installation, unfavorable energy saving, large maintenance, etc., to reduce hardware investment, The effect of enriching software design and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

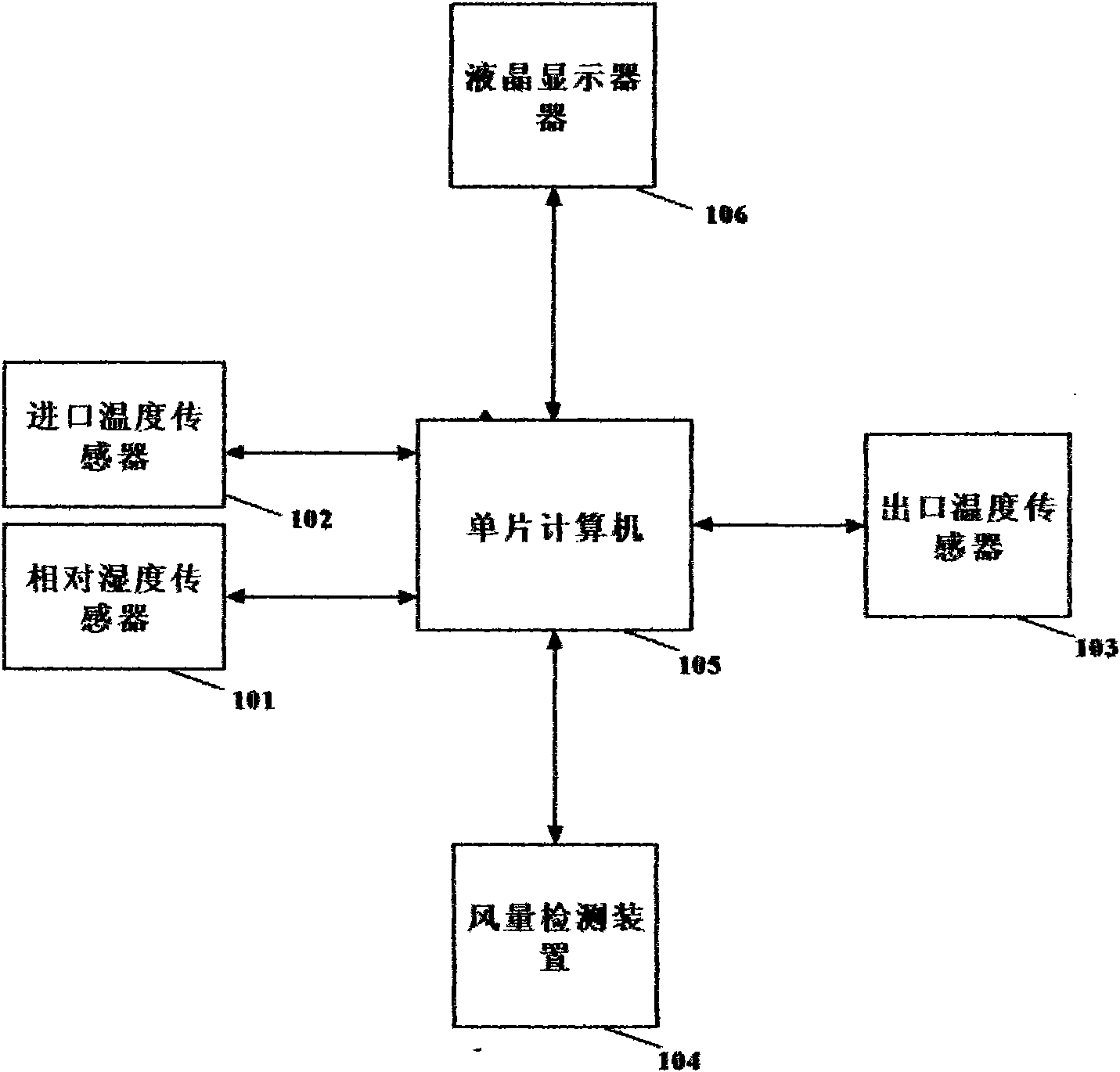

[0052] See figure 1 , figure 1 It is a hardware block diagram of the fan coil air conditioner cooling / heat metering system of the present invention.

[0053] In this embodiment, both the inlet temperature sensor 102 and the outlet temperature sensor 103 of the fan coil unit are digital temperature sensors, and the relative humidity sensor 101 is a digital humidity sensor. The humidity sensor 101 and the temperature sensor 102 are placed at the air inlet of the fan coil unit, and the temperature sensor 103 is placed at the air outlet of the fan coil unit. The single-chip computer 105 adopts a 16-bit low-power single-chip microcomputer, and the liquid crystal display 106 displays cooling capacity, heat supply, inlet and outlet temperatures and working hours. The temperature sensor 102 , the temperature sensor 103 , the relative humidity sensor 101 , the air volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com