Shear flow sensor

A sensor and shear flow technology, applied in the field of sensors, can solve the problems of small deformation and easy breakage of piezoelectric ceramics, and achieve the effects of good stability, uniform force and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

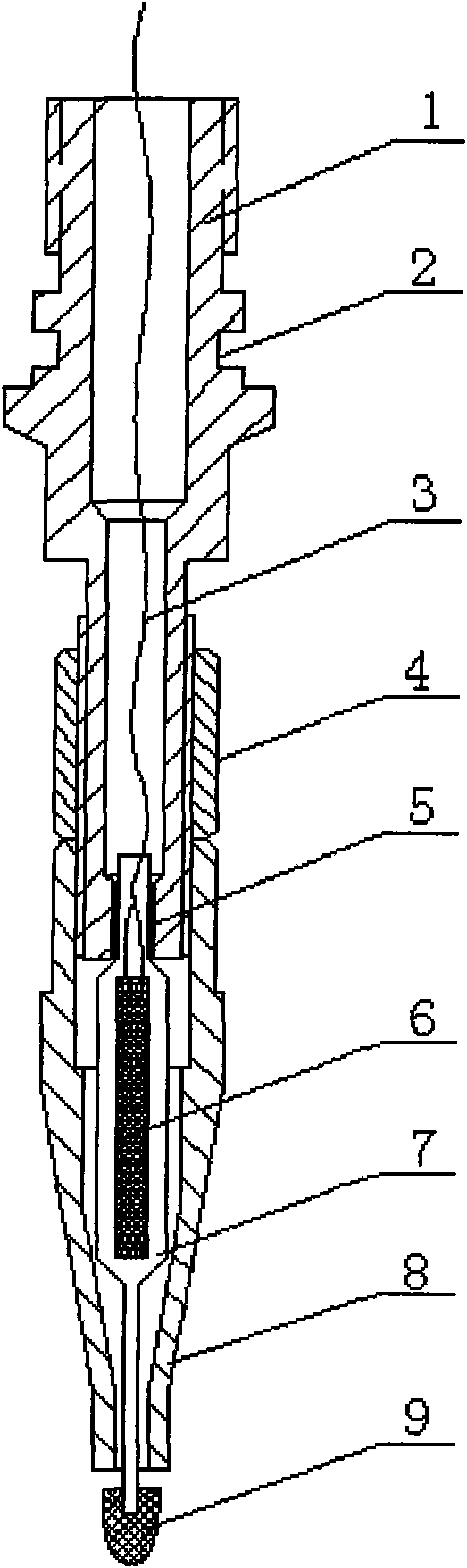

[0031] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

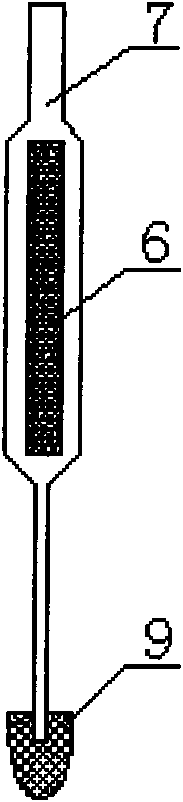

[0032] The invention discloses a shear flow sensor, which uses the piezoelectric effect of a piezoelectric film material to measure ocean turbulent force. Such as figure 2 As shown, the present invention mainly includes a piezoelectric film substrate 7 with a piezoelectric film 6 sealed on its surface, and a probe 9 is provided at one end of the piezoelectric film substrate 7 .

[0033] The piezoelectric film matrix 7 is generally a sheet structure, and the piezoelectric film 6 is pasted on one or both sides of the piezoelectric film matrix 7. When pasted on both sides, the test signal will be strengthened accordingly, so usually Just paste it on one side. The piezoelectric film 6 and the piezoelectric film base 7 must be closely pasted without gaps to achieve a sealed state. The thickness of the piezoelectric film 6 is usually in the range of 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com