Cabin type gas sampler

A gas sampler and cabin-type technology, applied in the direction of sampling devices, etc., can solve the problems of complex vacuum processing procedures for sampling bottles, gas container restrictions, sample gas pollution measurement, etc., and achieve the effects of simple structure, pollution avoidance, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

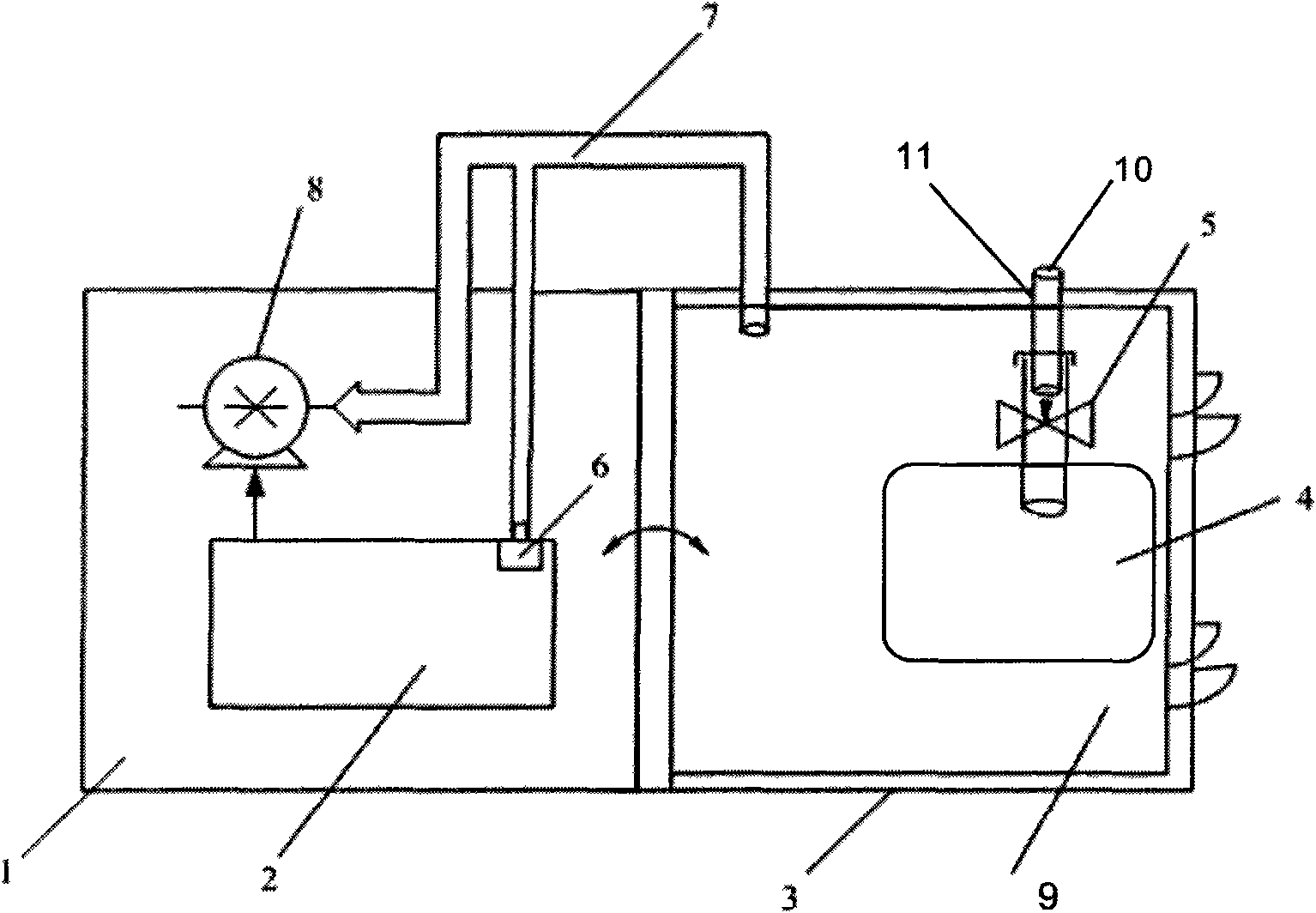

[0015] Such as figure 1 As shown, the cabin gas sampler includes a control system 1 and a sealed cabin 3 . Wherein, the control system 1 includes a controller 2 and an air pump 8, the controller 2 is electrically connected to the air pump 8, and controls the action of the air pump 8 by outputting a control signal, the controller 2 is provided with a pressure sensor 6, and the air pump 8 communicates with The pipeline 7 is connected with the inside of the airtight cabin 3 and the pressure sensor 6 pressure introduction end, and the pressure sensor 6 detects the negative pressure value in the airtight cabin 3, and outputs the signal to the controller 2; the controller 2 is connected with the air pump 8 to Control the air pump 8 to pump air, and the controller 2 is set as a time setting controller for immediate control, or it can be set as other time setting controls, such as timing and delay setting control, or it can be set as a pressure setting controller ; Of course, the act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com