Greenhouse combining aluminum-alloy glass structure with membrane structure

A technology of aluminum alloy and membrane structure, applied in greenhouse cultivation, botanical equipment and methods, climate change adaptation, etc., to achieve the effect of reducing steel consumption, smooth drainage, and smooth water accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

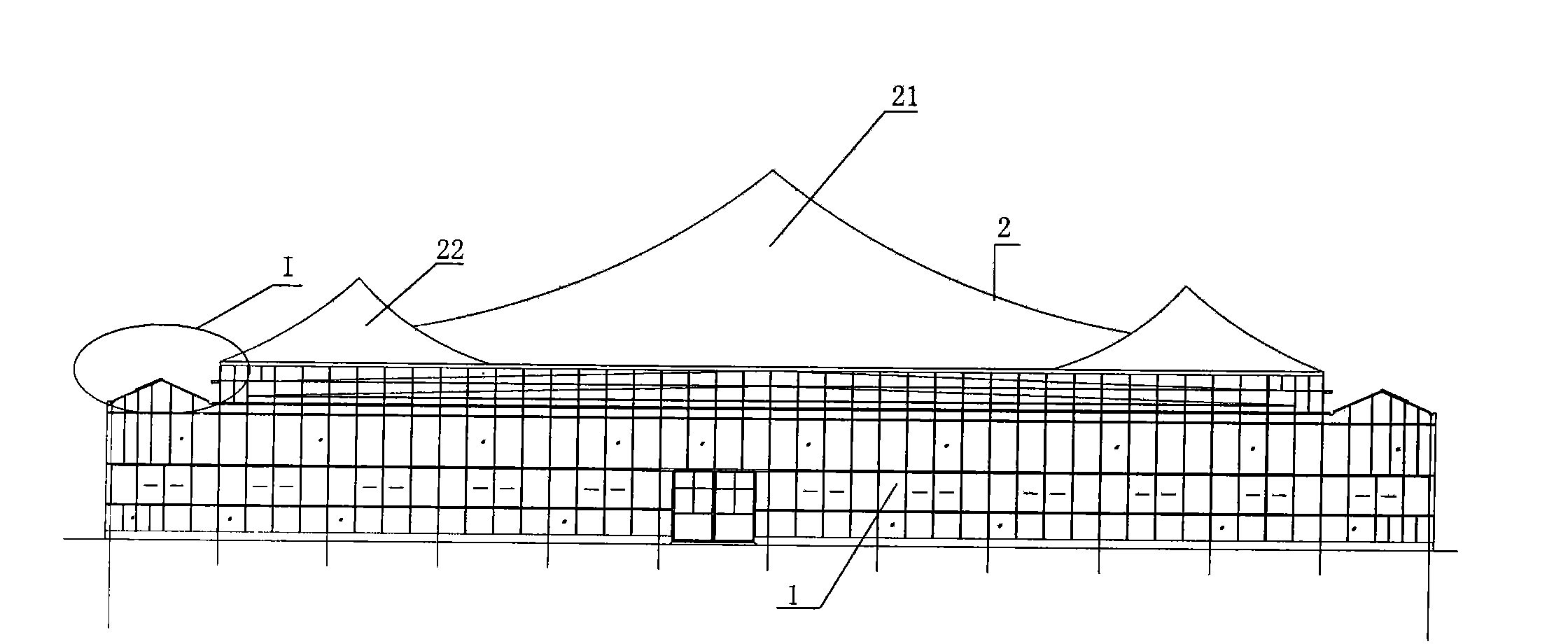

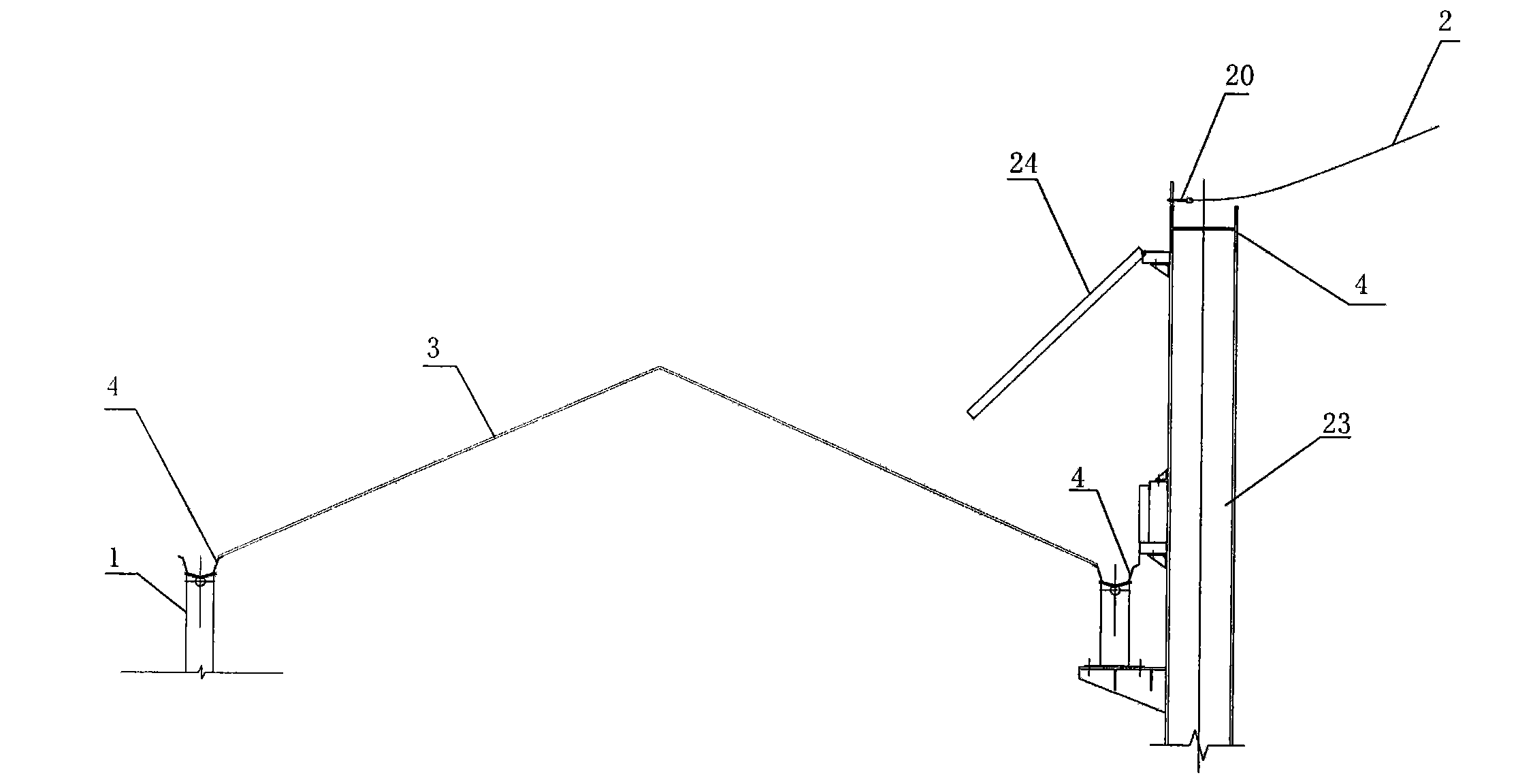

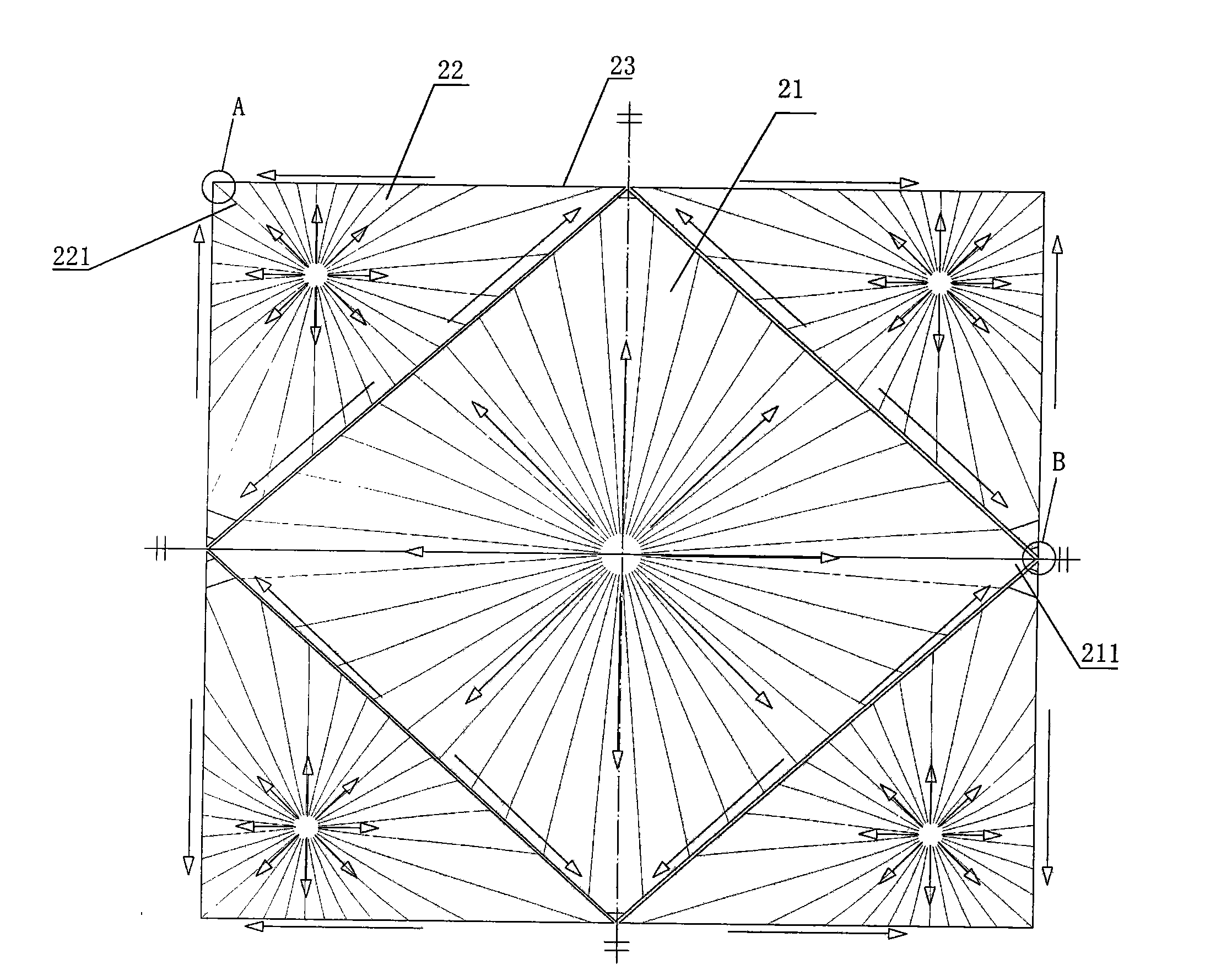

[0018] see figure 1 , the greenhouse of the present invention is mainly composed of a glass vertical wall surface 1 with an aluminum alloy frame and a top made of film cloth 2, the glass vertical wall surface 1 plays a role of heat preservation, and the film cloth 2 is arranged on the top It can provide a relatively tall space, with beautiful shape and full of the flavor of the times. The top formed by the membrane cloth 2 includes a main column arranged in the middle of the membrane cloth, the main column is provided with a main membrane cloth 21, a plurality of slave columns around the main column, and the slave membrane cloth 22 is arranged on the main column. The height of the column is greater than that of the secondary column, and the are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com