Method for processing differential case assembly

A technology of differential case and processing method, which is applied in the direction of differential transmission, geared components, transmission box, etc., which can solve the problems of differential case fracture, low product strength, easy breakage, etc., and achieve extended use Life expectancy, product quality assurance, and the effect of promoting enterprise development

Inactive Publication Date: 2010-01-27

鞠小平

View PDF0 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Due to the rapid development of the national economy, the sales of automobiles have also increased rapidly correspondingly, but at the same time it has also brought many problems. Among them, the fracture of the differential case of auto parts is not uncommon. The product has low strength, small static torsional torque, and is easy to break. , low life

It has brought great losses and troubles to enterprises and users

Method used

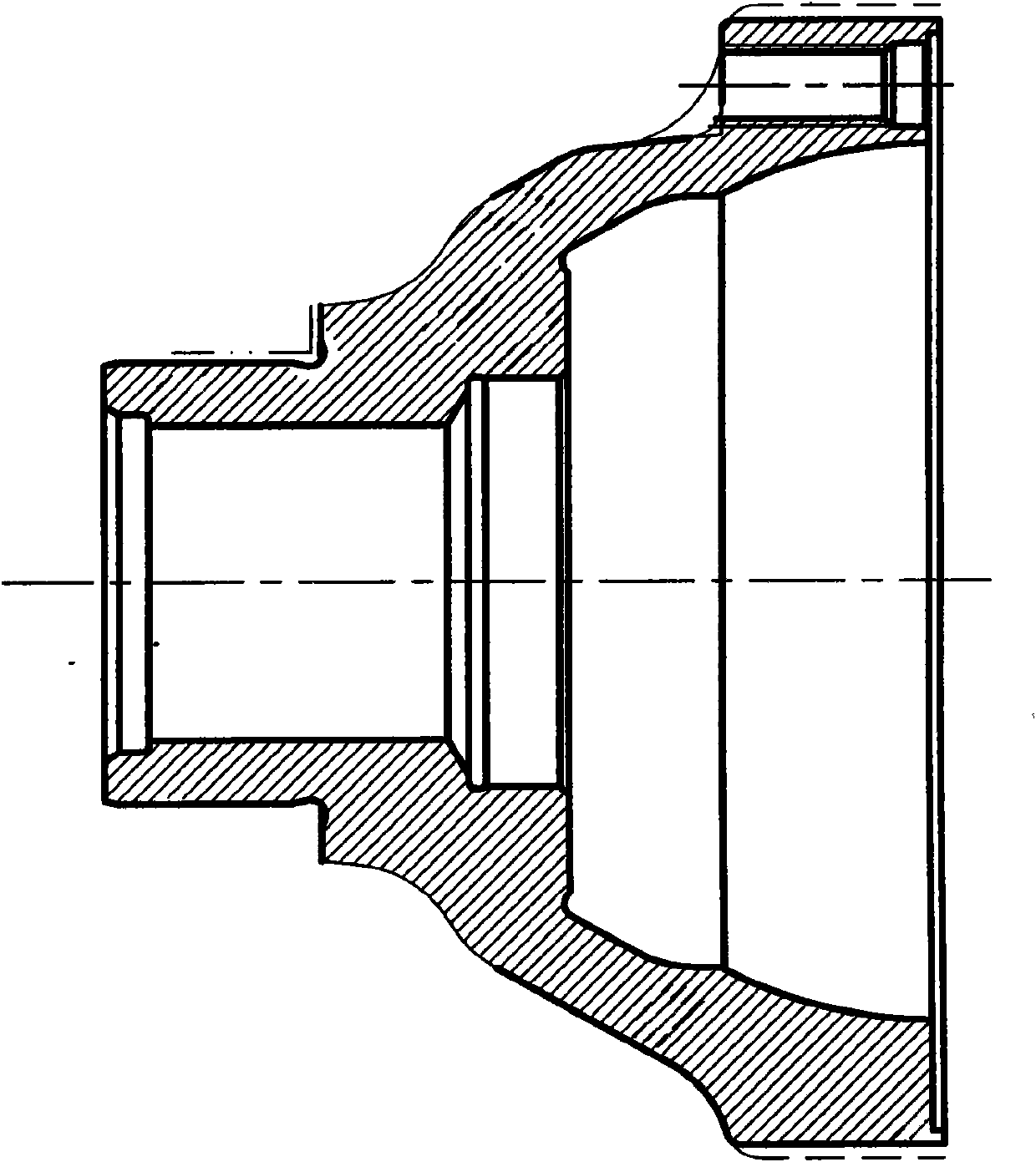

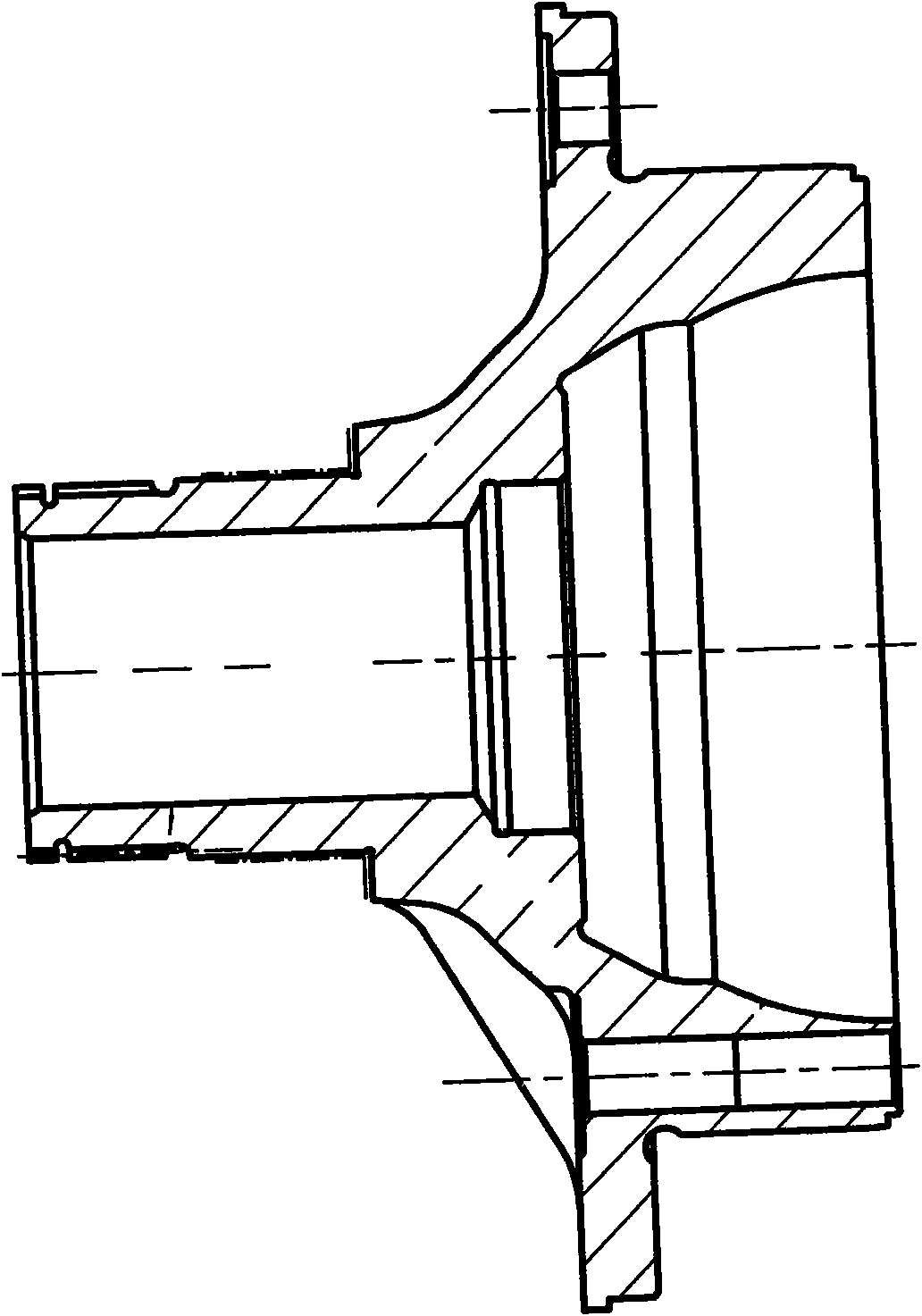

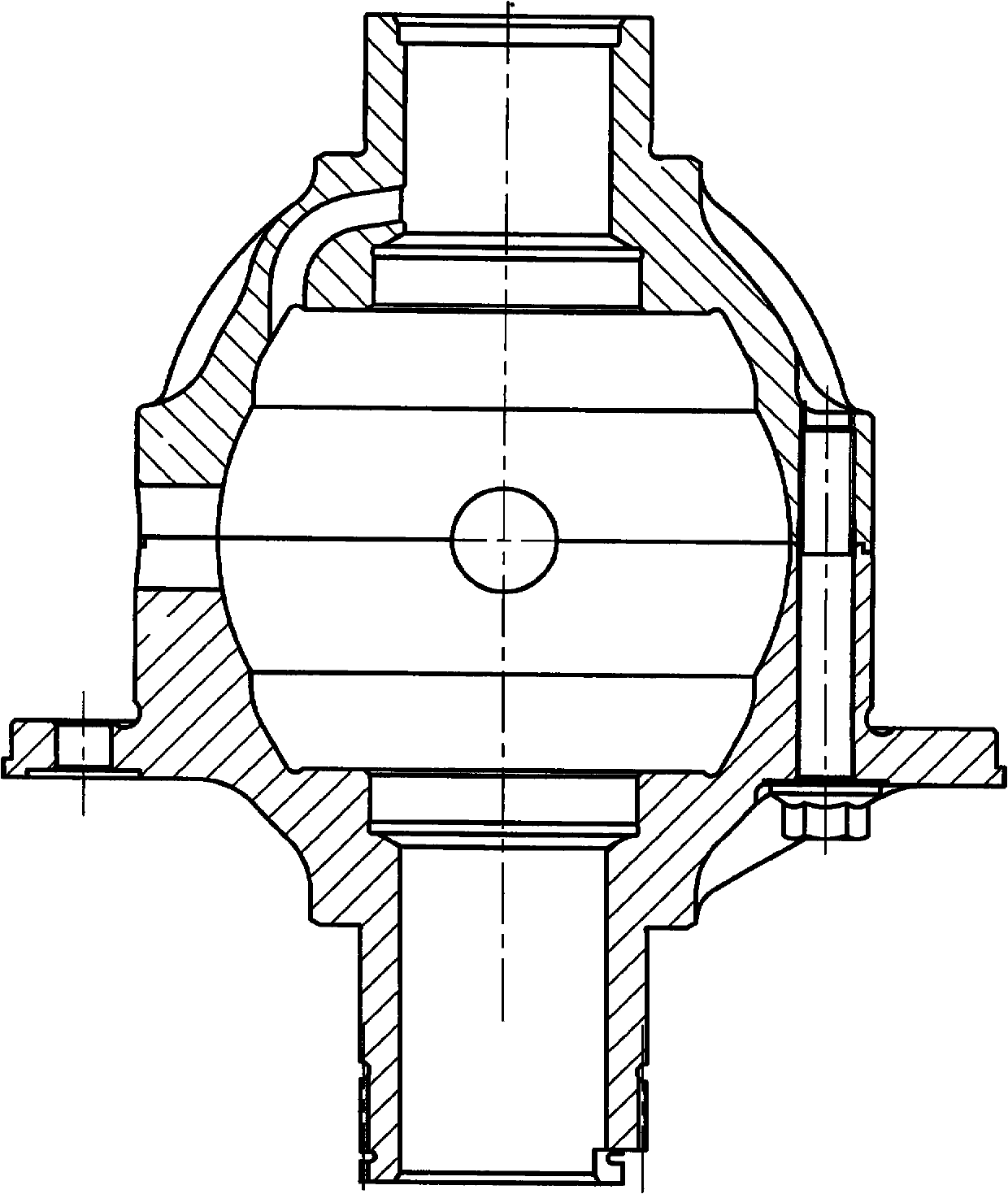

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

[0009] Below in conjunction with accompanying drawing, the present invention will be further described;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for processing a differential case assembly, which comprises the steps of processing a front half case of a differential, processing a back half case of the differential, performing induction quenching on excircle surfaces of small ends of two workpieces and within 25mm of a shoulder step, and assembling the differential case assembly. In the assembling process, two half cases are connected firmly by eight bolts, the coaxiality is corrected on special equipment and not allowed to exceed phi0.025, and the end jump is not more than 0.025; excircles are ground, wherein double core clampers grind the excircles and end faces of the two half cases of the differential, and all machining dimensions are ground to meet the requirements of a drawing; a crossed hole is milled, wherein a mill chuck is arranged and clamped, and a crossed hole is milled on a fit position of the two half cases according to the requirements of the drawing; and the machining dimensions are detected by corresponding measuring tools. The method is a good processing method, which can save a product, ensure product quality, prolong the service life of the product, reduce cost and promote enterprise development.

Description

technical field [0001] The invention relates to auto parts, in particular to a processing method for the differential case assembly of the auto parts. Background technique [0002] Due to the rapid development of the national economy, the sales of automobiles have also increased rapidly correspondingly, but at the same time it has also brought many problems. Among them, the fracture of the differential case of auto parts is not uncommon. The product has low strength, small static torsional torque, and is easy to break. , low lifespan. It has brought great losses and troubles to enterprises and users. Contents of the invention [0003] The purpose of this invention is to provide a kind of processing method of differential case assembly, which can well overcome the problems existing in the above products, and the purpose of the present invention is achieved in this way, the processing method of differential case assembly , characterized in that: processing the front half s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23P15/00F16H57/02F16H48/00

Inventor 张伟

Owner 鞠小平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com