Device for taking and putting crystalline grain and method thereof

A technology of grain and predetermined position, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of inability to adjust, different sizes, etc., and achieve the effects of avoiding damage to grains, simplifying assembly methods, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

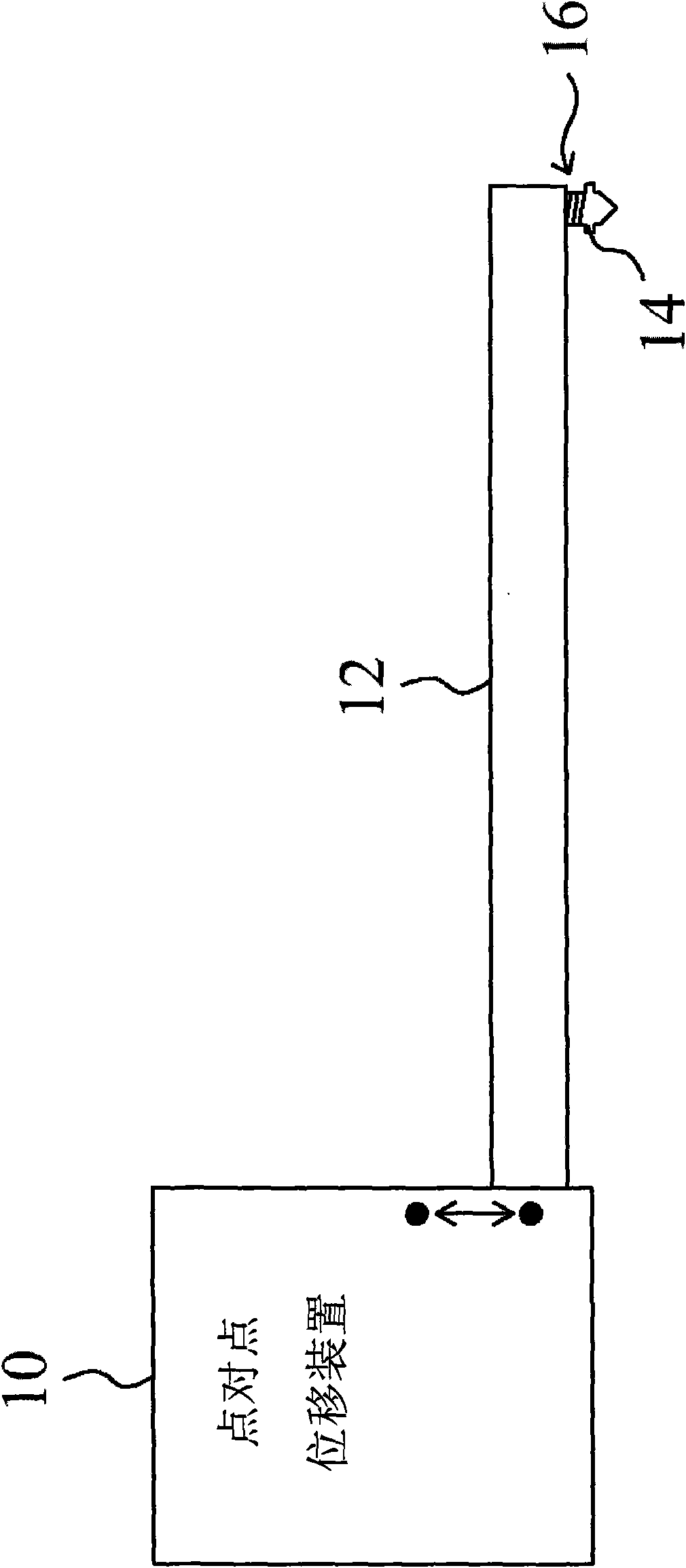

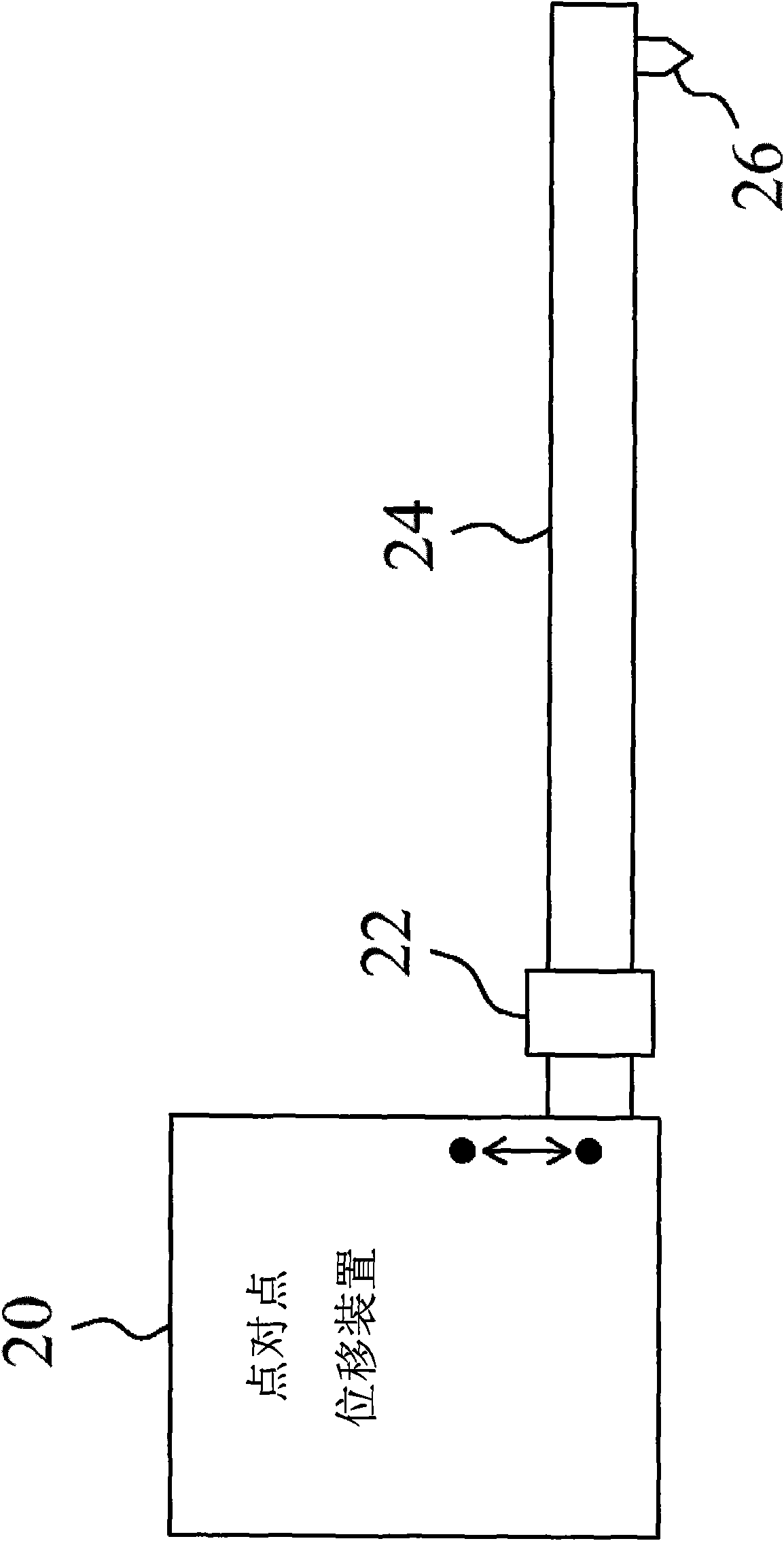

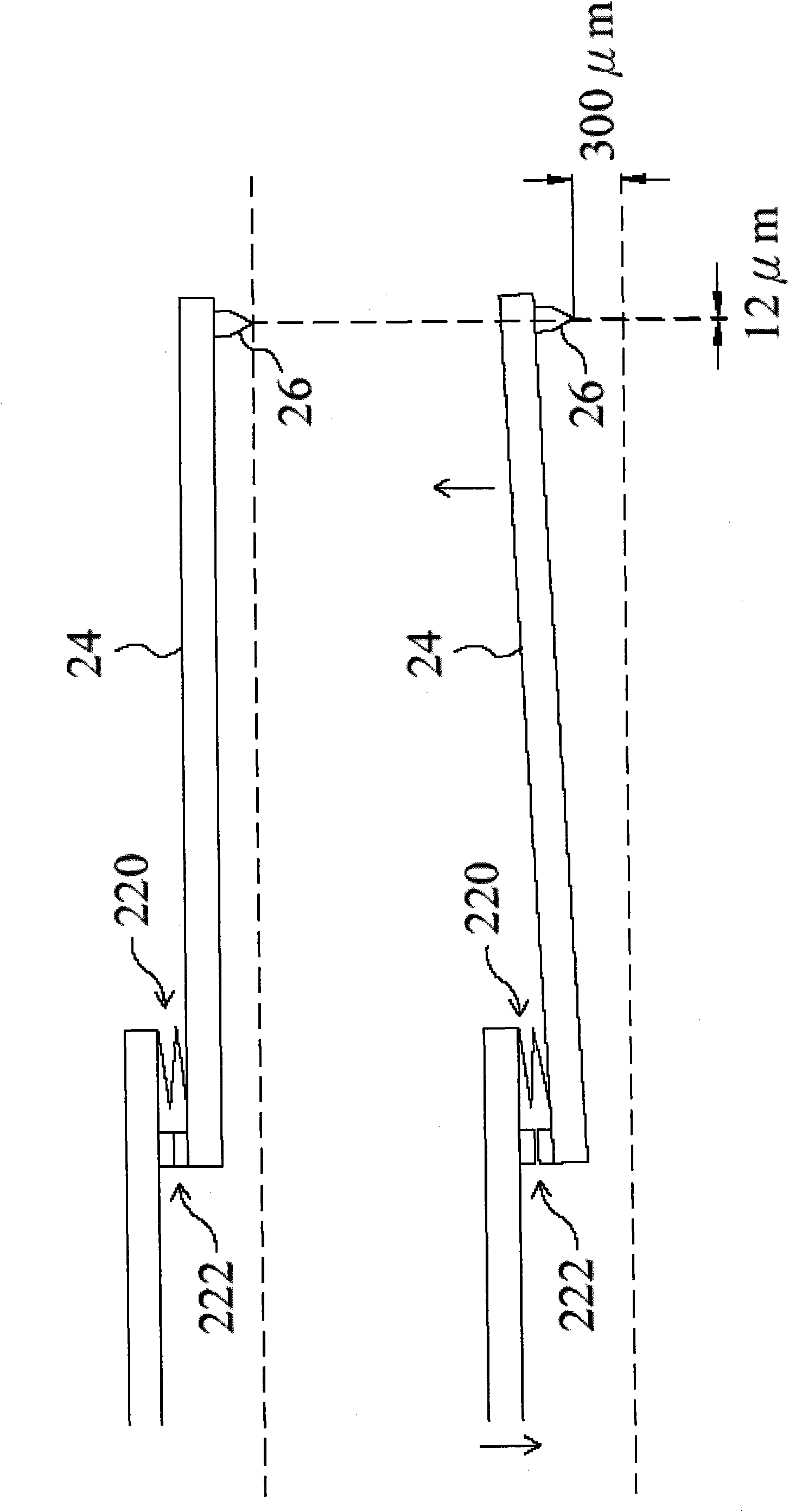

[0068] see now Figure 5 and Figure 6 , Figure 5 It is a schematic diagram of an embodiment of the present invention, Figure 6 for Figure 5 Example working schematic. As shown in the figure, the displacement control device 40 is connected to a swing arm 42, the front end of the swing arm 42 is equipped with a suction head 44, and the displacement control device 40 controls the vertical movement of the swing arm 42 so that the suction head 44 descends on the crystal. Grain 46 on. In this embodiment, the displacement control device 40 controls the movement of the swing arm 42 in at least two stages. When picking up the crystal grain 46, first operate in the first stage mode, such as point-to-point displacement control, let the suction head 44 drop to a certain distance above the crystal grain 46 at a faster speed, and then enter the second stage mode,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com