Plasma generation equipment rendered electrically neutral on the periphery of plasma gun

A plasma and generation device technology, applied in the direction of plasma, ion implantation plating, circuit, etc., can solve the problem of loss of thin film uniformity, and achieve the effect of reducing and suppressing the transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

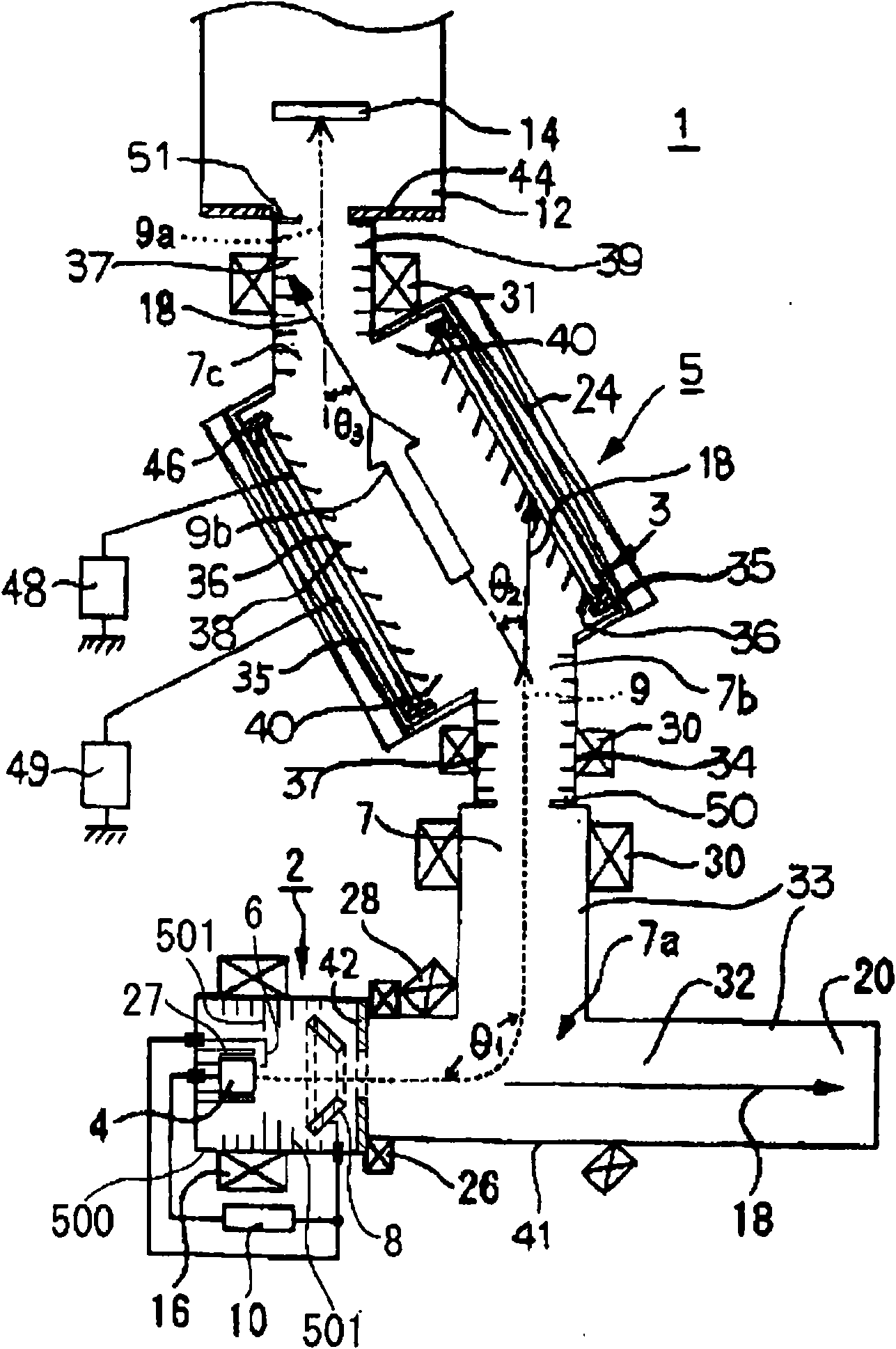

[0180] Hereinafter, embodiments of the plasma generation device according to the present invention will be described in detail with reference to the drawings. In the present invention, both an apparatus provided with a plasma processing unit (unit to be treated with plasma) for processing an object to be processed and an apparatus without a plasma processing unit are included as plasma generating apparatuses. A plasma generation device having a plasma processing unit may also be referred to as a plasma processing device.

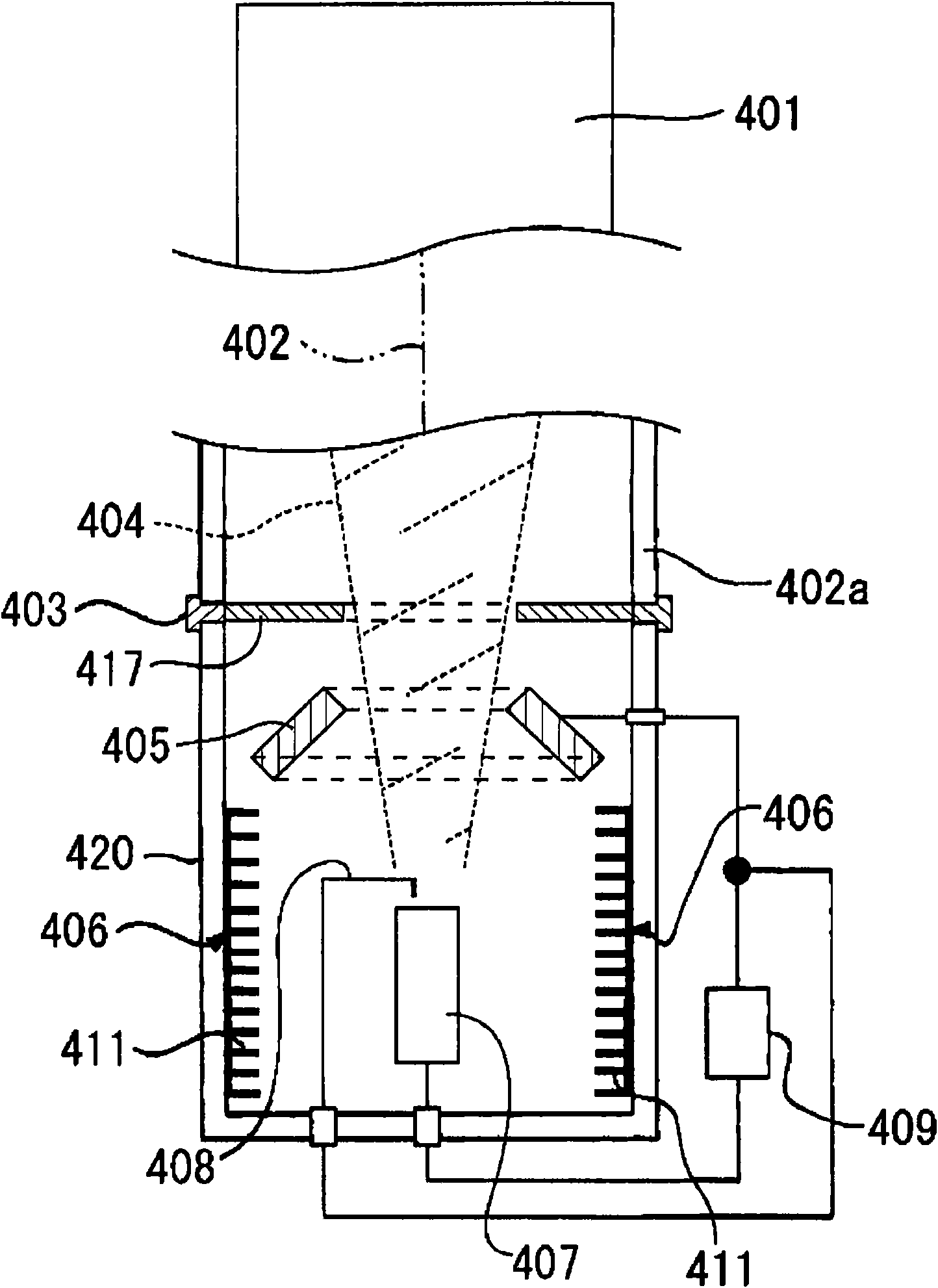

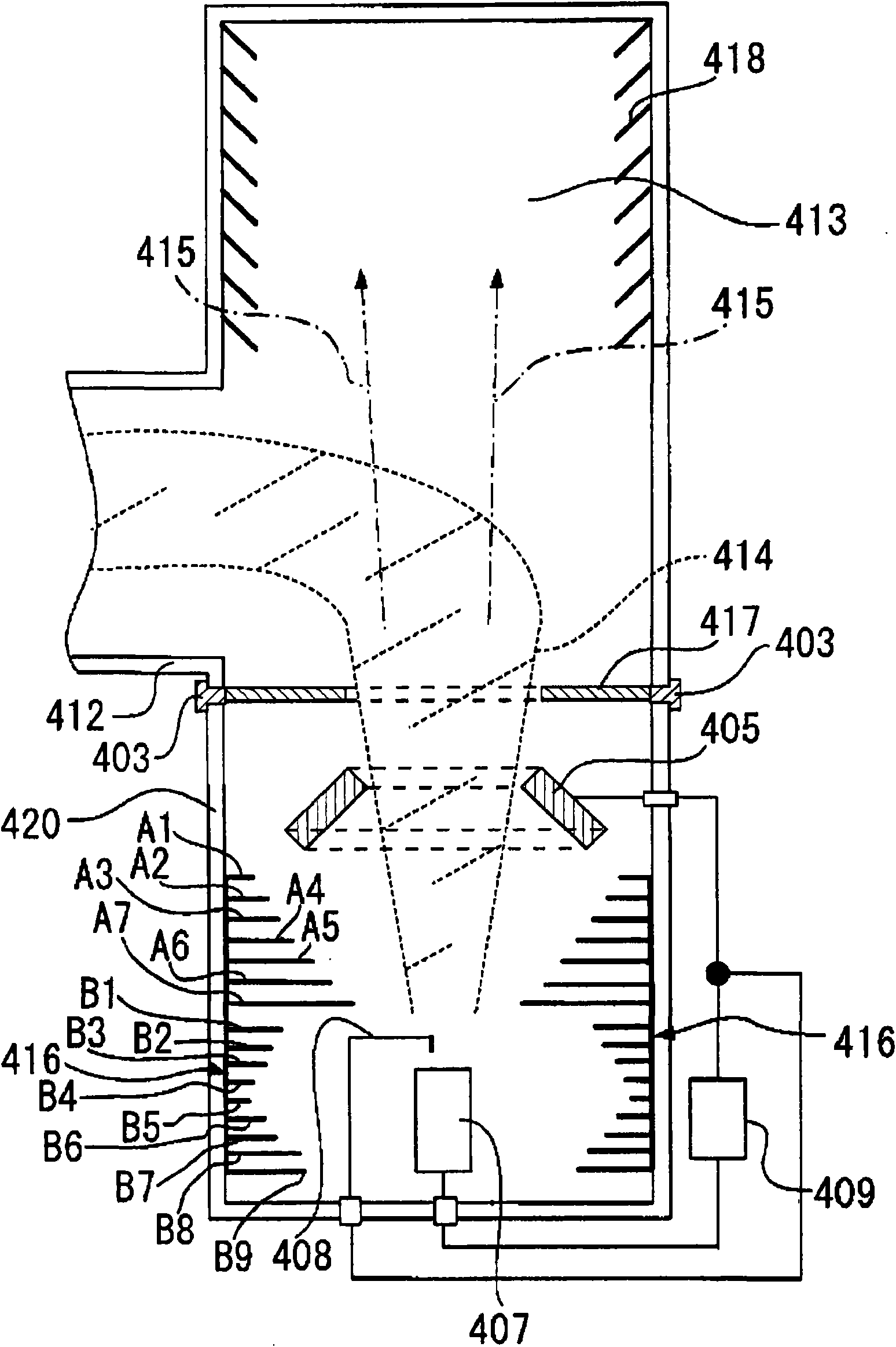

[0181] figure 1 It is a schematic configuration diagram of the plasma generation device according to the present invention. figure 1 The plasma generating apparatus shown is composed of a plasma generating unit (plasma tube) for generating plasma by vacuum arc discharge in a vacuum atmosphere, a plasma processing unit 401 , and a plasma traveling path 402 . In the description of the present invention, the plasma advancing path 402 means the path from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com