Jack-up platform

A self-elevating platform and pile leg technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of not disclosing the effective method of controlling the driving mechanism, etc., and achieve the effect of increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

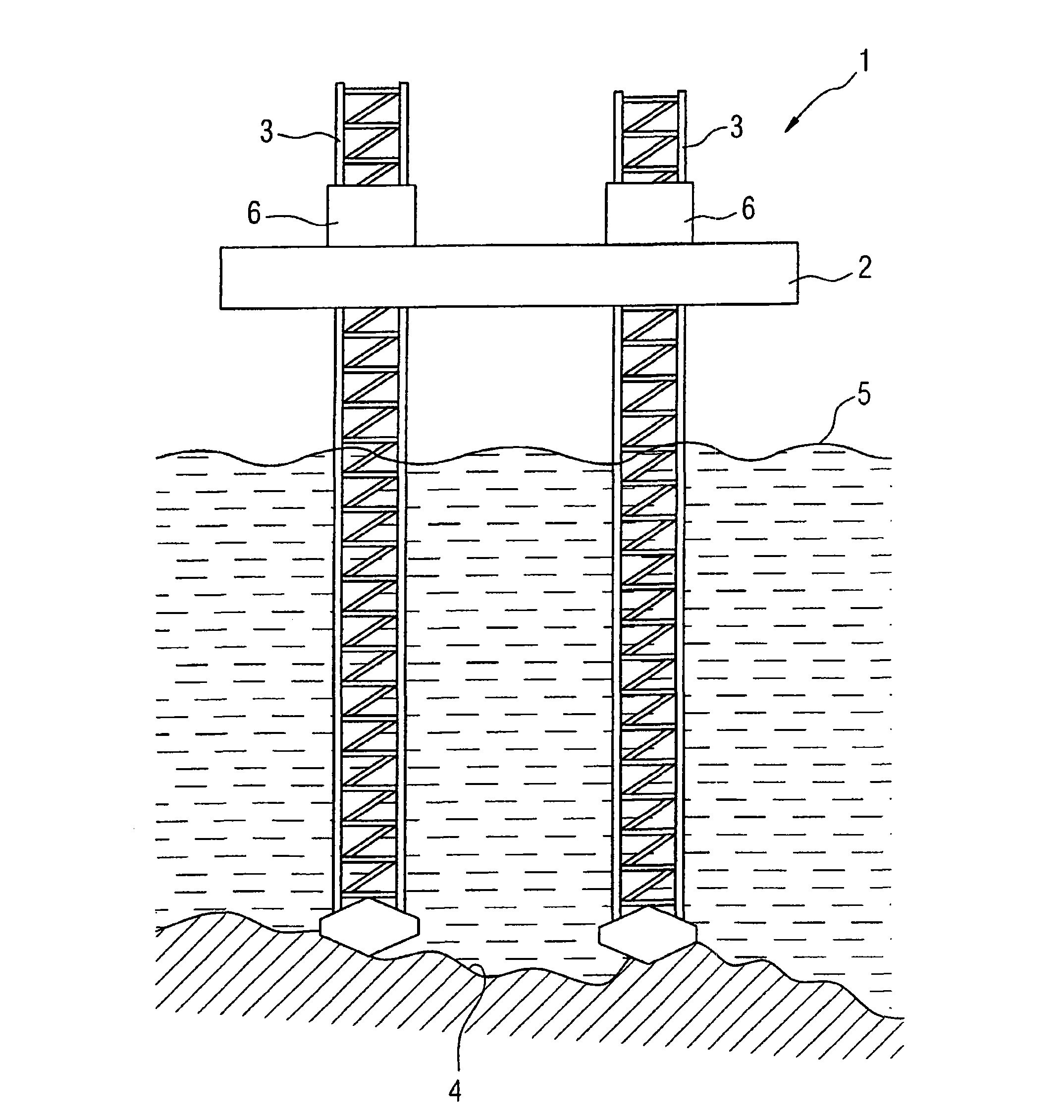

[0027] figure 1 An offshore jack-up platform 1 is schematically shown in the sea. It comprises a hull 2 and some parallel, longitudinally movable legs 3 (ie 4, only two of which are shown). The hull 1 carries eg drilling equipment for oil field exploration. exist figure 1 In the state shown, all legs 3 are placed on an inclined seabed 4 as a fixed foundation. Hull 1 lifts 5 several meters above water level.

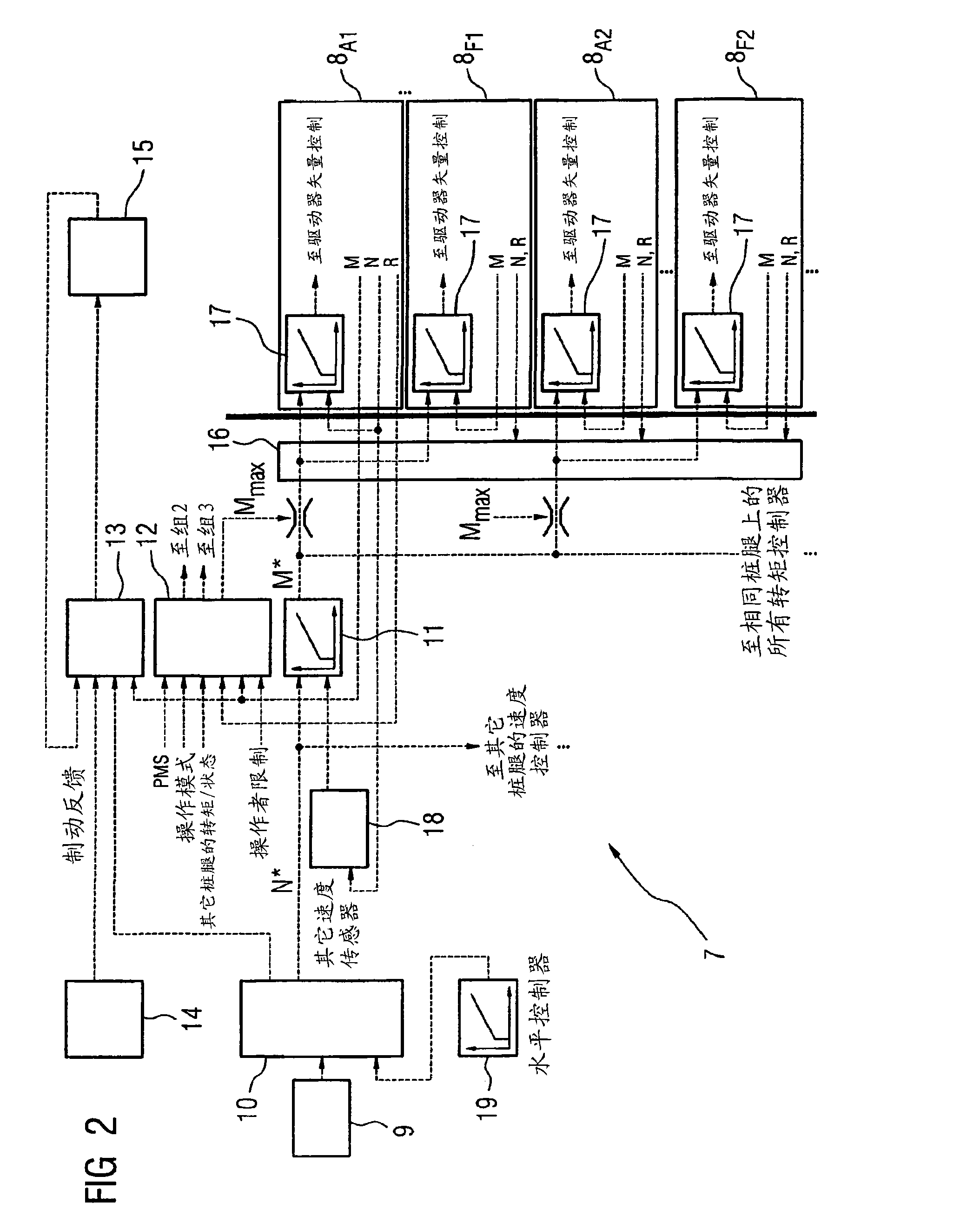

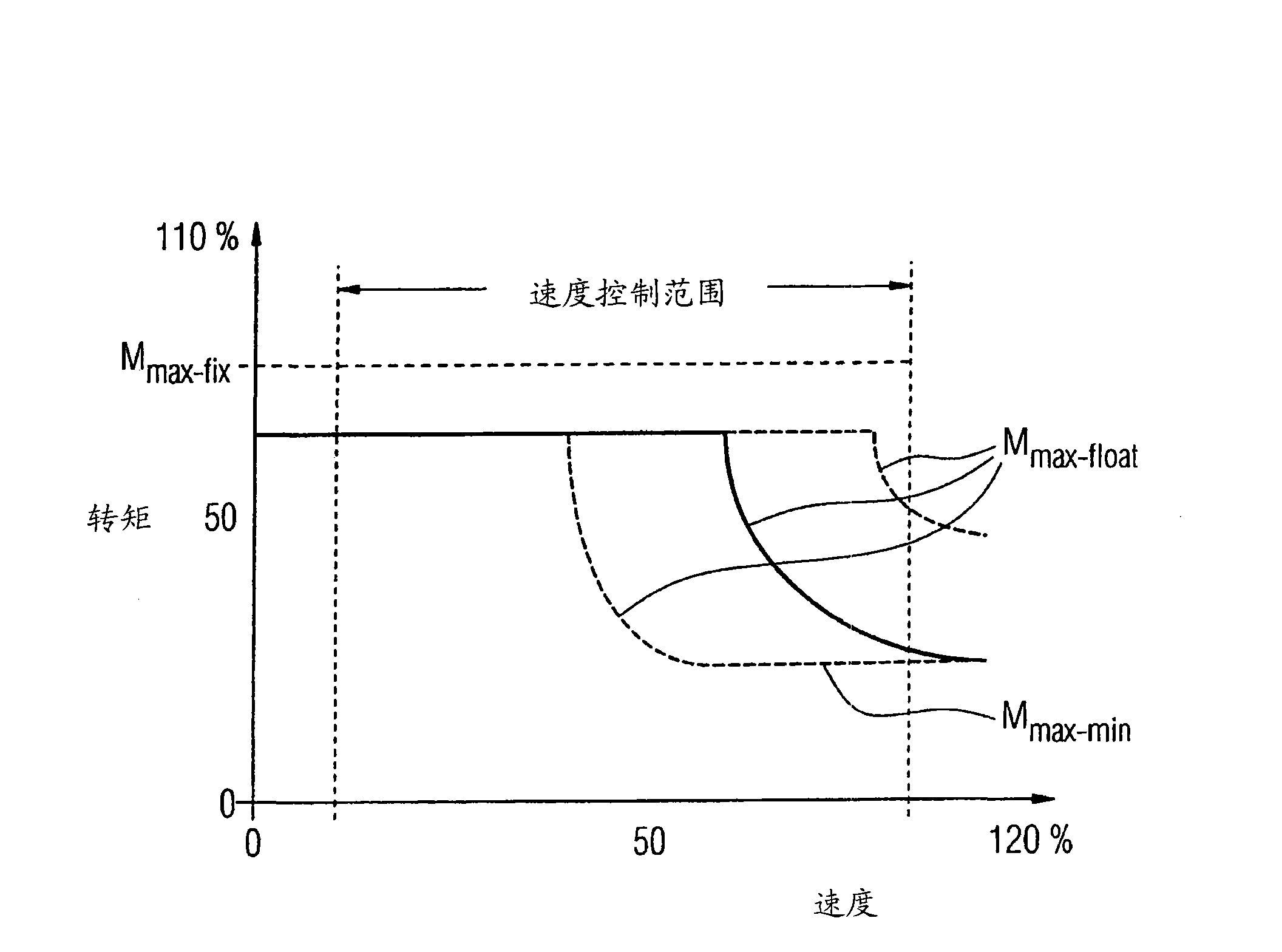

[0028] Each leg 3 is equipped with a driving mechanism 6 that contains a plurality of corresponding variable speed drives, i.e. 18 ( figure 1 not shown), the drive mechanism drives the rack-and-pinion device, and the drive mechanism is shared with all legs 3 closed-loop control unit ( figure 1 not shown) together. For example for triangular legs, the variable speed drives of each leg 3 are assigned to three separate groups, each group having its own drive A to F. They comprise permanent magnet motors (not shown) driving the legs 3 with infinitely variable speed. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap