Emergency separating device for liquid transmission

A detachment device, emergency technology, applied in the direction of special distribution devices, etc., can solve the problems of low work efficiency, easy to cause accidents, affect the next use, etc., achieve good safety and reliability, reduce labor intensity, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

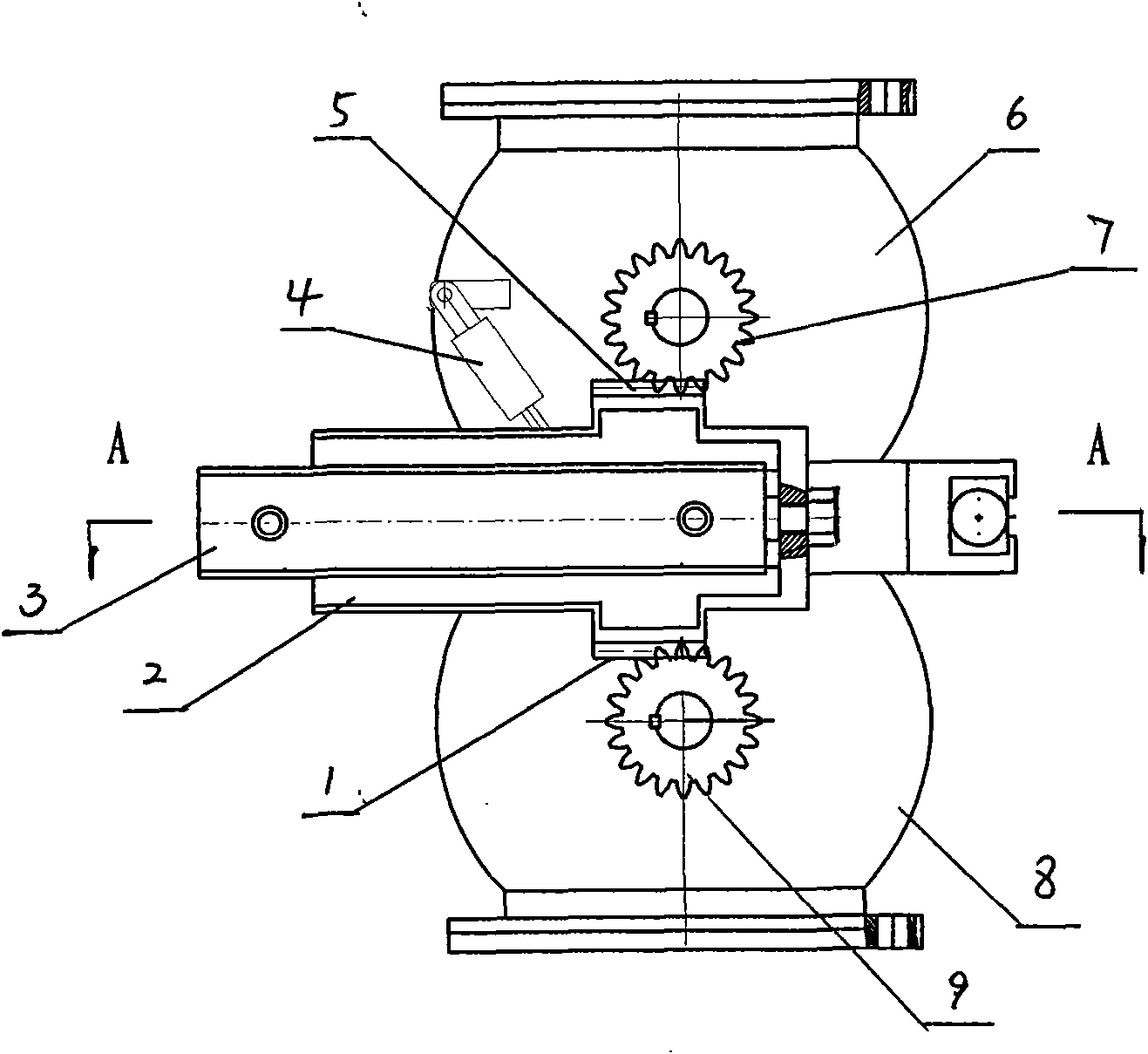

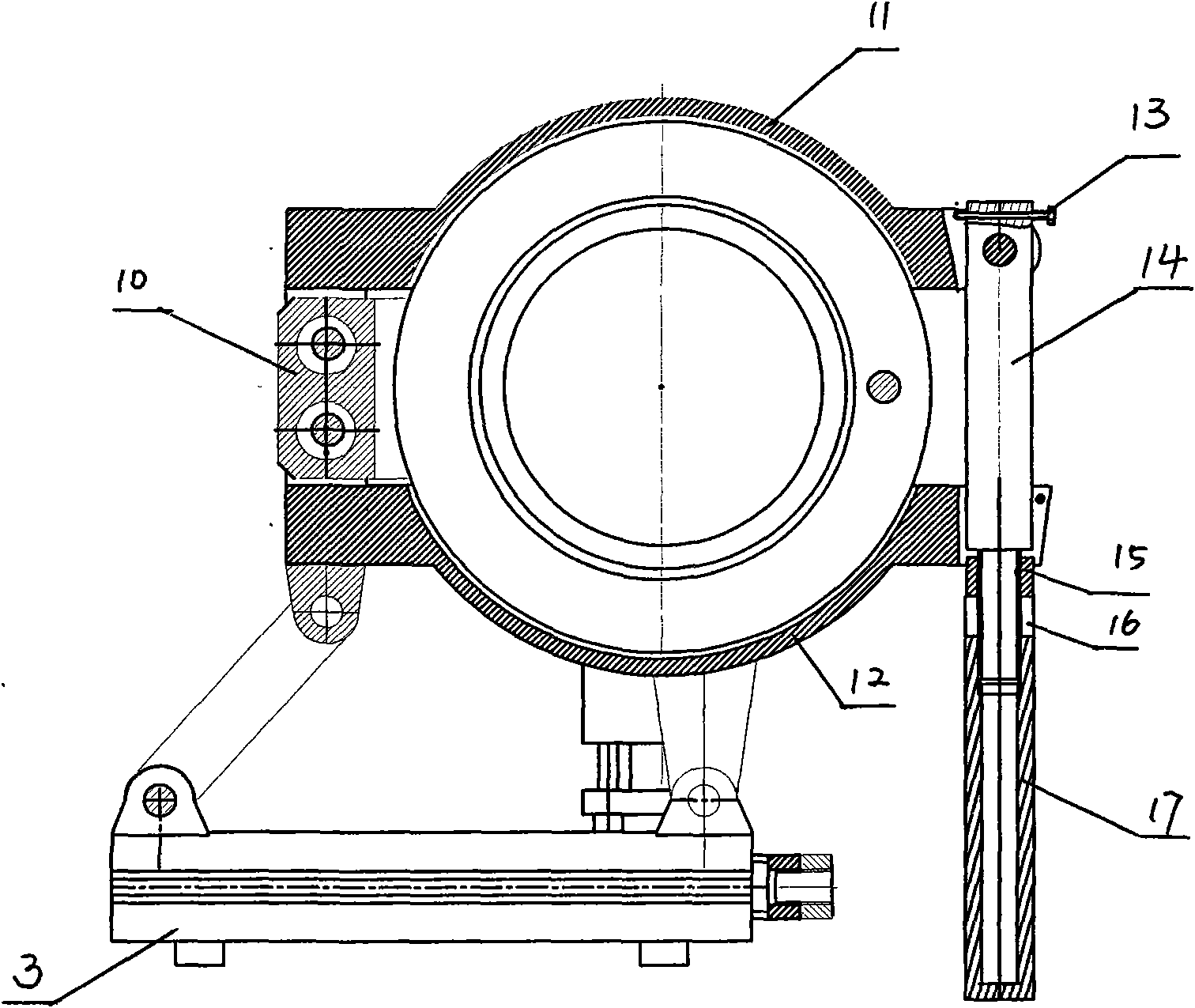

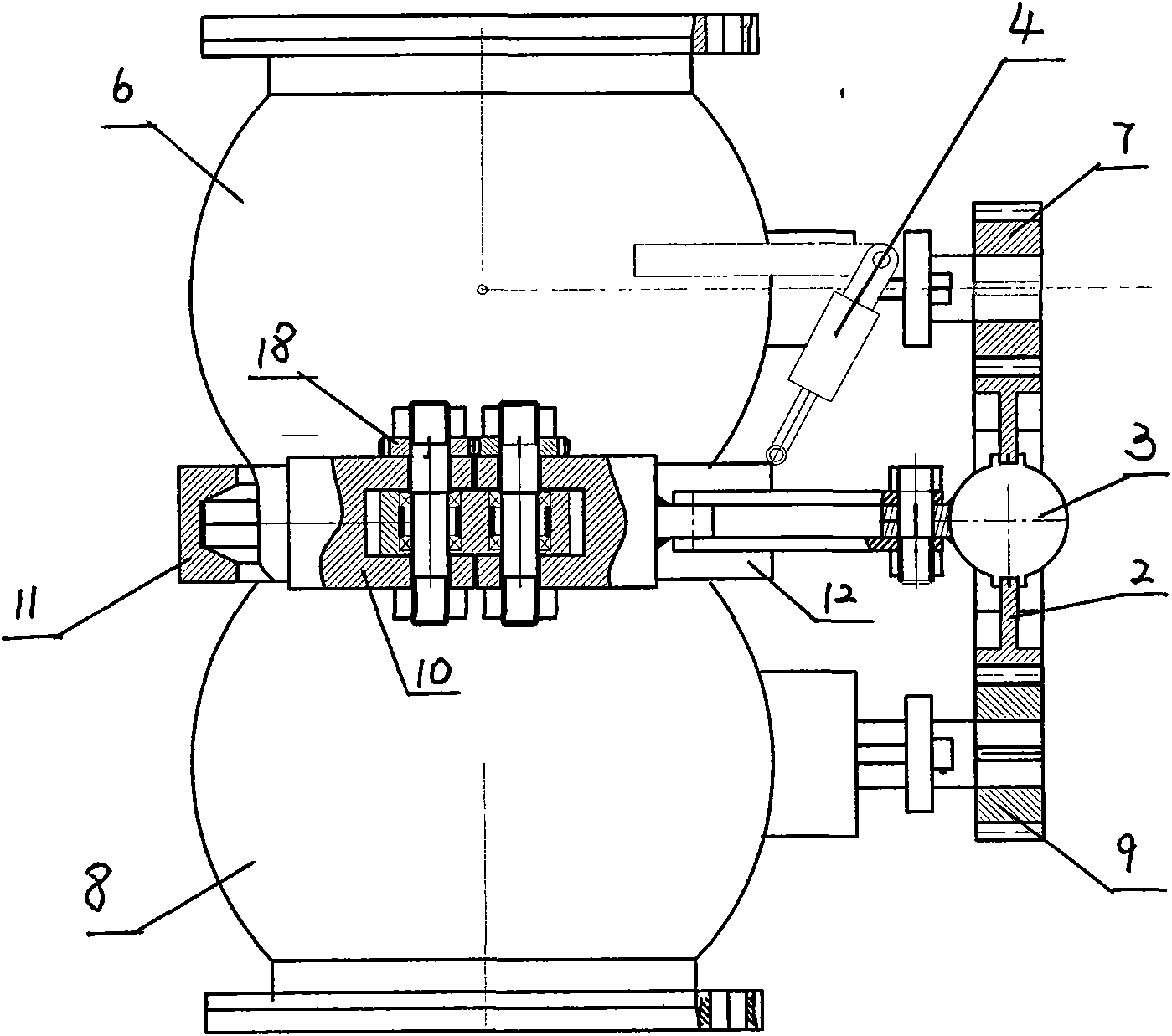

[0014] An emergency release device for liquid delivery, including upper and lower valve bodies 6, 8 and a locking assembly, the locking assembly includes a front clamping plate 12, a rear clamping plate 11, a clamping plate seat 10, a locking rod 14, and a locking nut 16 and gasket 15, the clamp seat 10 is fixedly arranged on the side of the upper valve body 6, and the valve core rotating rod of the upper and lower valve body is arranged on the front of the upper and lower valve body, and the end of the valve core rotating rod is equipped with The transmission gear 7,9 is provided with a transmission block 2 driven by an oil cylinder 3 between the two transmission gears 7,9, and the transmission block 2 is provided with upper and lower racks 5,1 cooperating with the two transmission gears. One end of the locking lever 14 is hinged with the rear clamping plate 11 through a horizontal shaft, and the other end of the locking lever 14 is engaged in the outward jaw of the front clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com