Far infrared heating shell fabric

A far-infrared heating and far-infrared fiber technology, applied in the direction of electric heating devices, ohmic resistance heating, cellulose/protein conjugated artificial filaments, etc., can solve the problems of unsightly appearance, poor warmth retention effect, discomfort, etc., and achieve The effect of enhancing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

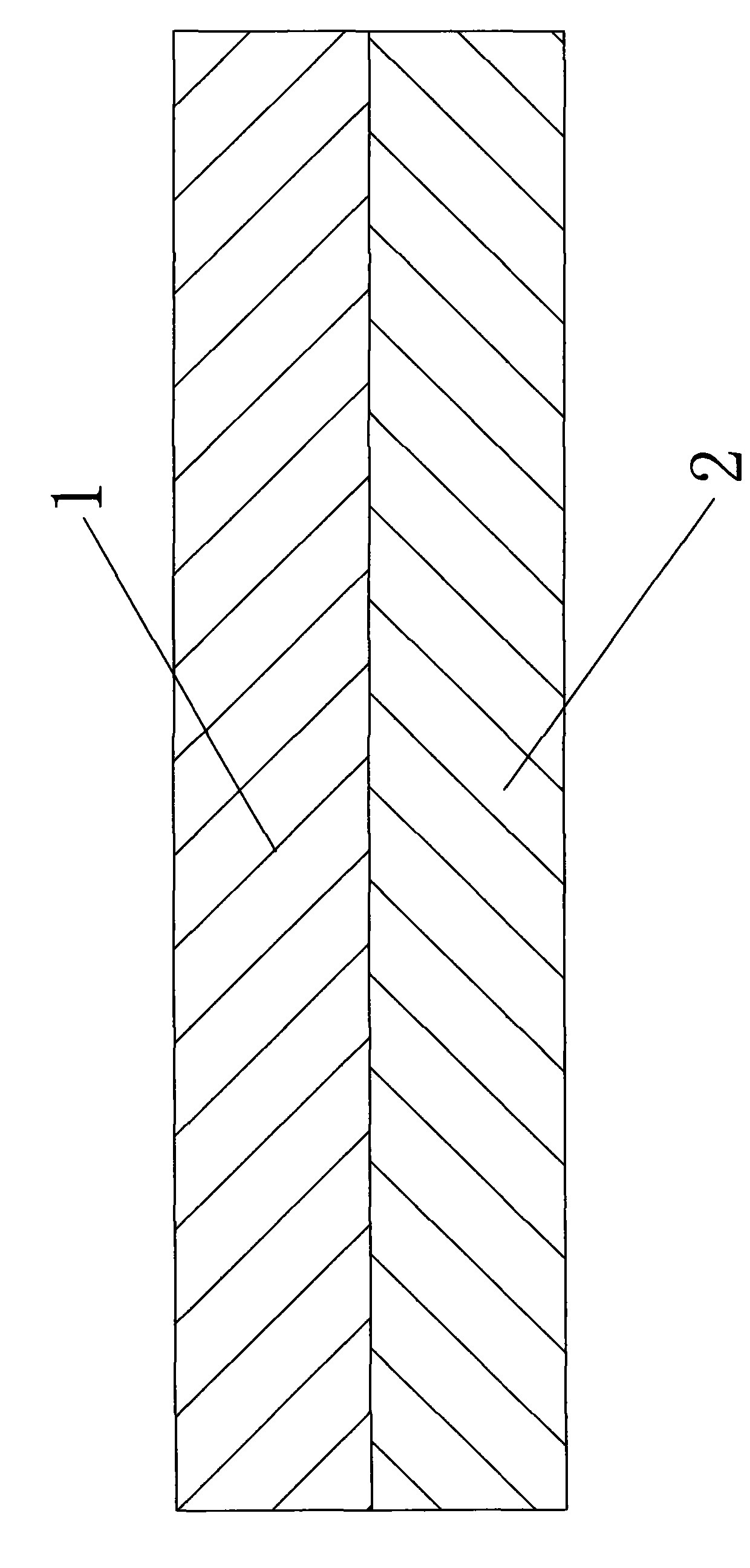

[0022] like figure 1 The far-infrared heating fabric shown includes two layers, including an inner layer 1 of a far-infrared fiber layer and an outer layer 2 of a near-infrared fiber layer. The inner layer 1 of the far-infrared fiber layer is blended with 10% far-infrared fiber material and 90% wool by weight. The far-infrared fiber layer fabric 1 is blended with 50% polyacrylonitrile mixed with ceramic powder and 50% cotton by weight percentage. The outer layer 2 of the near-infrared fiber layer is blended with 10% near-infrared fiber material and 90% wool. The near-infrared fiber material is made by blending 50% polyacrylonitrile doped with zirconium carbide and 50% cotton. Wherein the gram weight of the fabric after dyeing and finishing is 250 grams square meters.

Embodiment 2

[0024] like figure 1 The far-infrared heating fabric shown includes two layers, including an inner layer 1 of a far-infrared fiber layer and an outer layer 2 of a near-infrared fiber layer. The inner layer 1 of the far-infrared fiber layer is made of 50% far-infrared fiber material, 20% spandex and 30% wool blended by weight. The far-infrared fiber layer fabric 1 is blended with 50% polyacrylonitrile mixed with ceramic powder and 50% cotton by weight percentage. Wherein the near-infrared fiber layer fabric outer layer 2 is formed by blending 60% near-infrared fiber material, 10% spandex and 30% wool. The near-infrared fiber material is made by blending 50% polyacrylonitrile doped with zirconium carbide and 50% cotton. Wherein the gram weight of the fabric after dyeing and finishing is 250 grams square meters.

Embodiment 3

[0026] like figure 1 The far-infrared heating fabric shown includes two layers, including an inner layer 1 of a far-infrared fiber layer and an outer layer 2 of a near-infrared fiber layer. Wherein said far-infrared fiber layer fabric inner layer 1 is made of 100% far-infrared fiber material by weight percentage, wherein said far-infrared fiber layer fabric 1 is made of polypropylene nitrile mixed with ceramic powder by 50% by weight percentage Blended with 50% cotton. The outer layer 2 of the near-infrared fiber layer is made of 100% near-infrared fiber material; the near-infrared fiber material is blended with 50% polyacrylonitrile mixed with zirconium carbide and 50% cotton. Wherein the gram weight of the fabric after dyeing and finishing is 250 grams square meters.

[0027] The present invention uses two kinds of fiber yarns with different functions to interweave upper and lower needle faces on a circular knitting machine to form a double-layer structure fabric, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com