Permanent-magnet generator and windmill generator using the same

A generator, permanent magnet technology, applied in wind turbines, motors, wind power generation, etc., can solve the problem of reducing the efficiency of wind power generation, and achieve the effect of increasing the power generation voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

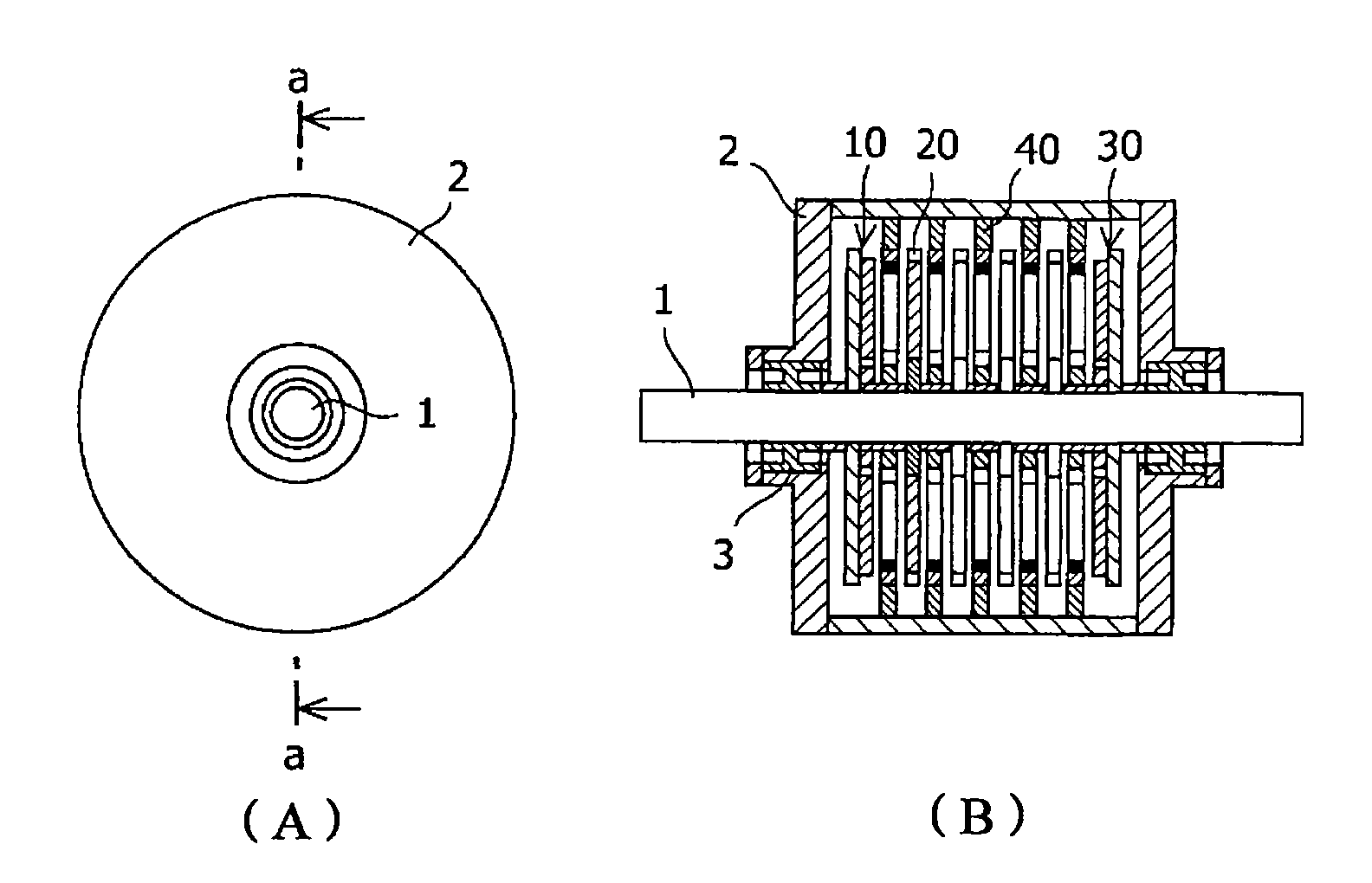

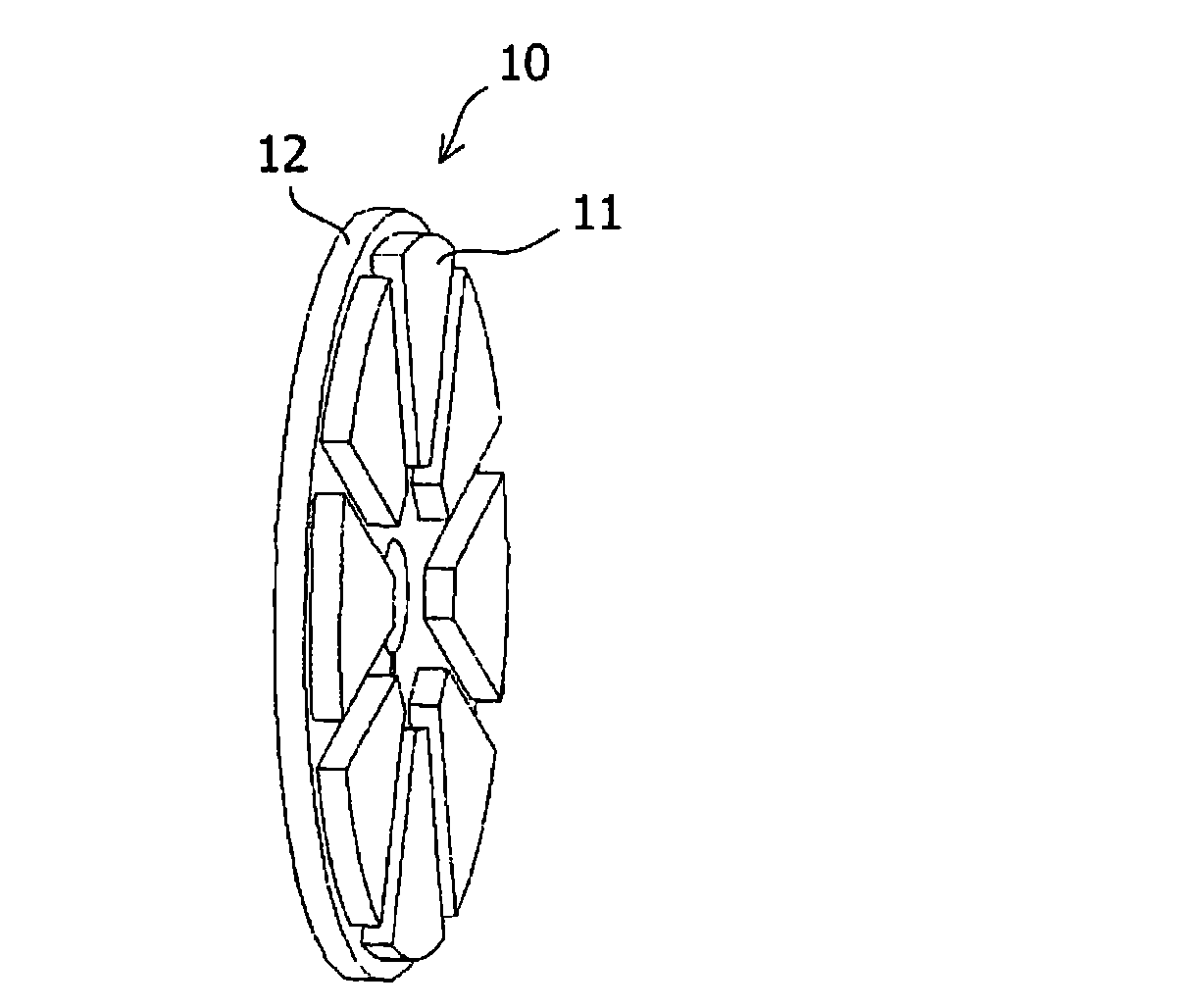

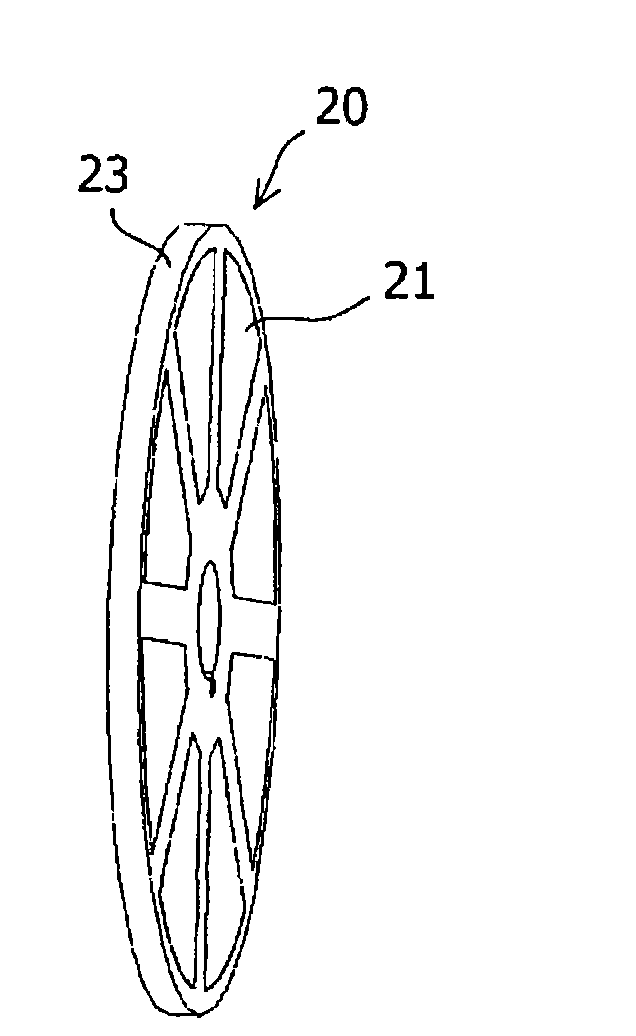

[0073] manufacture figure 1The generator shown in. Manufactured generators are designed with a variable number of stages for the rotor and stator, and the respective power generation voltages produced by changing the number of stages are measured. The shaft is made of stainless steel and has a diameter of 15mm. In the end rotor, eight NdFeB permanent magnets (poles oriented in the axial direction, thickness 4 mm) were concentrically adhered to a ferromagnetic yoke with a diameter of 100 mm and a thickness of 2 mm using an adhesive (epoxy resin), And arrange them in an alternating fashion so that the equidistant poles are oppositely oriented. In addition, in the inner rotor, a stainless steel member with a diameter of 100 mm and a thickness of 4 mm has eight equidistant holes formed for embedding magnets, and the same NdFeB permanent magnet (thickness: 4 mm) is embedded in each hole, and an adhesive (epoxy) fixed. Each rotor is connected to the shaft with a gap of 8 mm (th...

Embodiment 2

[0076] exist Figure 7 In , when the total weight of the magnets is the same, a comparison is made between (A) the three-stage case of two-stage rotor and one-stage stator and (B) the five-stage case of three-stage rotor and two-stage stator (the stator is not shown in the figure). The magnet structures of the rotor and the stator are the same as those of Embodiment 1. Each stator has the same specification. Each rotor has 8 magnetic poles, has a diameter of 100 mm, and has a rotor gap of 8 mm. Furthermore, in the case of the fifth stage, the thickness of the magnet is 4 mm, and in the case of the third stage, the thickness of the magnet is 6 mm. In stage five, the peak voltage is 18V at 450rpm. In level three, the peak voltage is 11V. Therefore, when using the same amount of magnets, the generated voltage can be greatly increased in the five-stage compared with the three-stage.

Embodiment 3

[0078] In another comparison, a three-stage generator having a two-stage rotor and one stator having an increased rotor diameter and an increased number of magnetic poles was compared with the five-stage generator of Embodiment 2. The magnet structures of the rotor and the stator are the same as those of Embodiment 1. The three-stage type generator has a rotor diameter of 130mm and has 10 magnetic poles, and the thickness of its magnets is set at 4.8mm so that the total weight of the magnets is the same as that of the five-stage type. In a three-stage generator, the peak voltage at 450 rpm is 17V. Therefore, although the three-stage type has a 30% larger diameter and a 69% larger surface area than the five-stage type of Example 2, the peak voltage is similar or even lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com