A swirling pool and its construction method

A construction method and swirling pool technology, applied in the direction of the settlement tank, etc., can solve the problems of unfavorable foundation pit dewatering, safety of large excavation side slopes, large excavation area of foundation pits, and deep construction work surface, etc., to improve the anti-floating effect. capacity, reduce the difficulty of precipitation, and save the effect of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

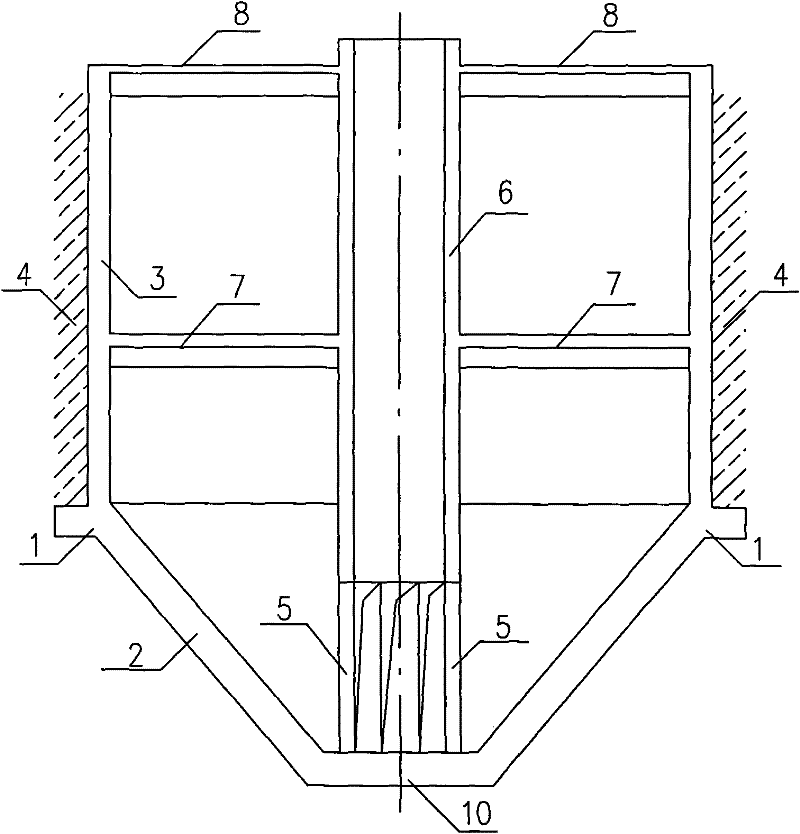

[0028] Embodiment 1: as figure 1 As shown, a swirl pool is provided with an external cantilever ring beam 1 at the junction of the inclined cone 2 and the outer cylinder 3 . This swirl pool is constructed according to the following steps: (1) Excavate the foundation pit to the bottom of the outer cylinder 3; (2) construct the outer ring beam 1; (3) the outer ring beam 1 is the foundation of the outer cylinder 3 construction stage , construction outer cylinder 3; (4) cut water and support soil retaining body 4, construct inclined cone 2 and bottom plate 10; (5) construct pillar 5, inner cylinder 6, pump room layer 7 and roof layer 8 from bottom to top.

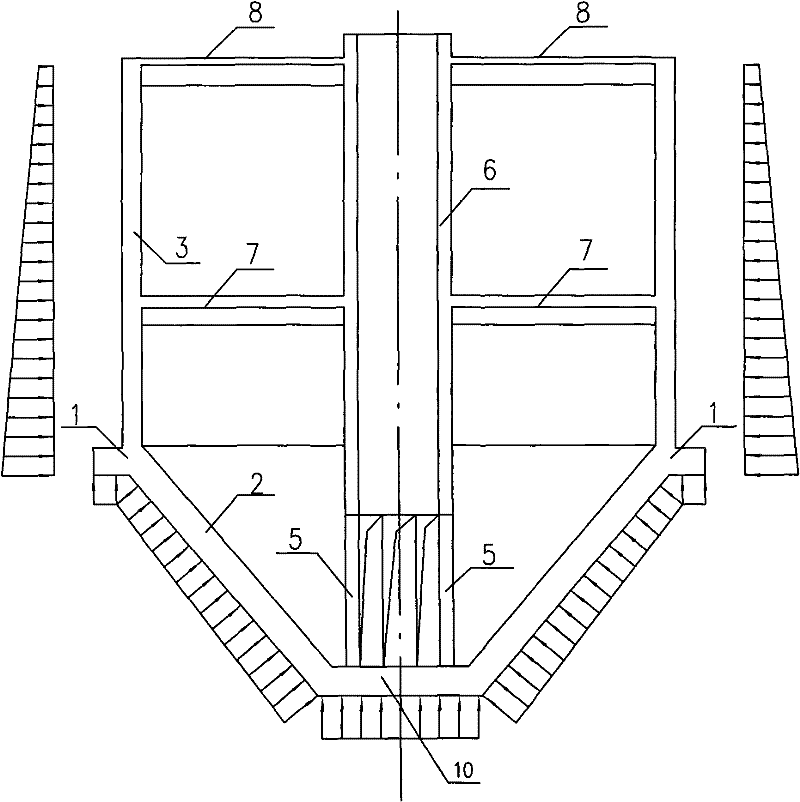

[0029] Such as figure 2 As shown, when the present invention is working, the earth pressure acts vertically on the lower surface of the inclined cone 2 and the bottom plate 10, and the outer hanging ring beam 1 constrains the top of the inclined cone 2, and the top of the inclined cone 2 generates an outward thrust, and the o...

Embodiment 2

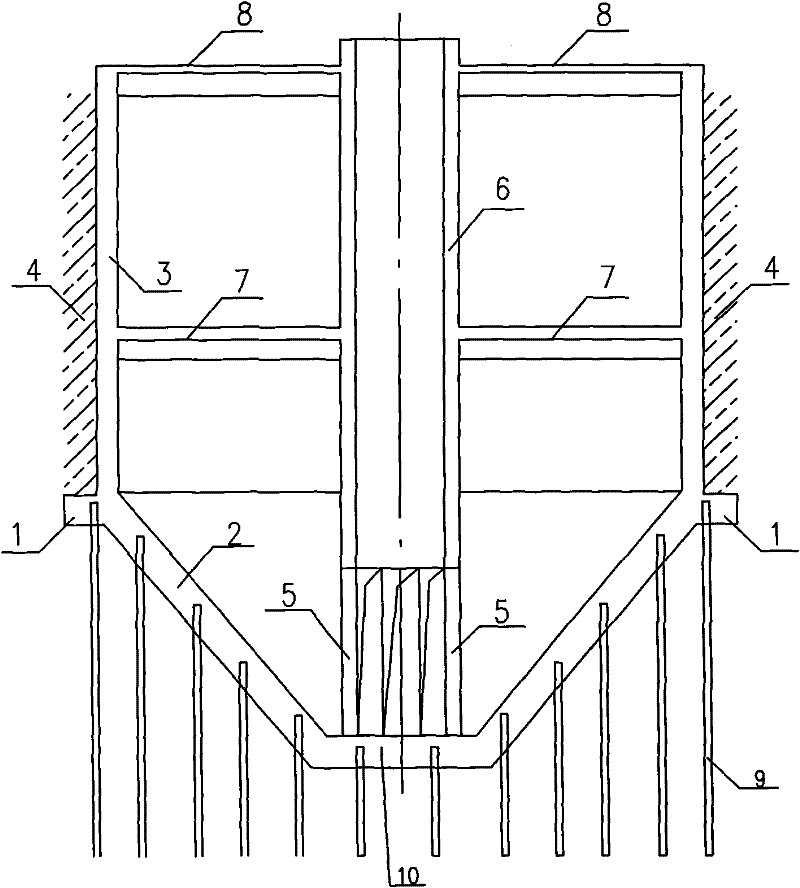

[0030] Embodiment 2: as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the lower part of the inclined cone 2 and the bottom plate 10 is provided with a group of bolts 9 anchored in the rock and soil. The bolt groups 9 are manufactured by high-pressure grouting technology. Other structures and construction methods of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com