Automobile electronic automatic gear changer

An automatic shifting, automotive electronics technology, applied in vehicle components, circuits or fluid pipelines, lighting applications, etc., can solve the problems of heavy weight of parts, poor hand feel, complex process, etc., to achieve a small number of parts and a small number of personnel. , check the simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

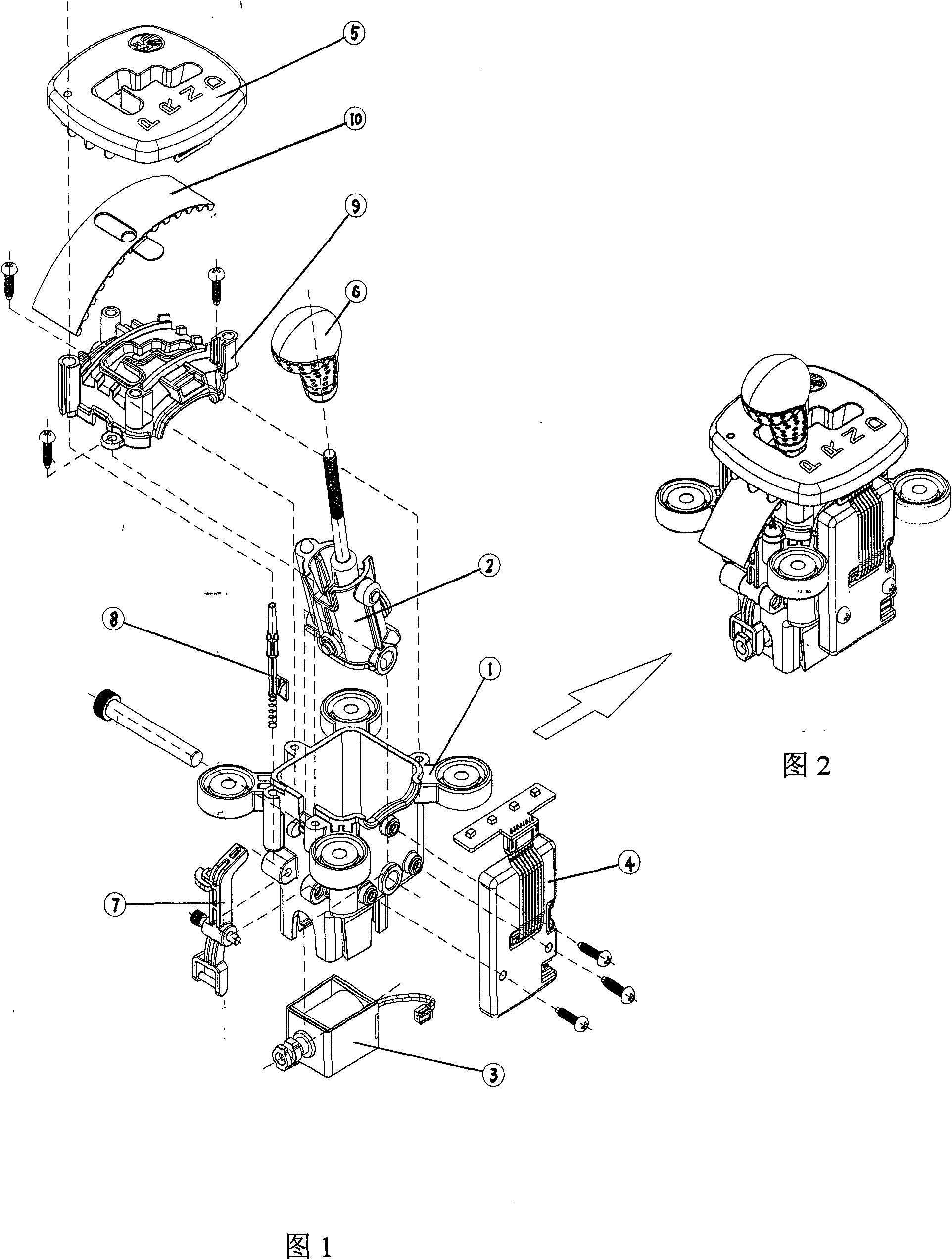

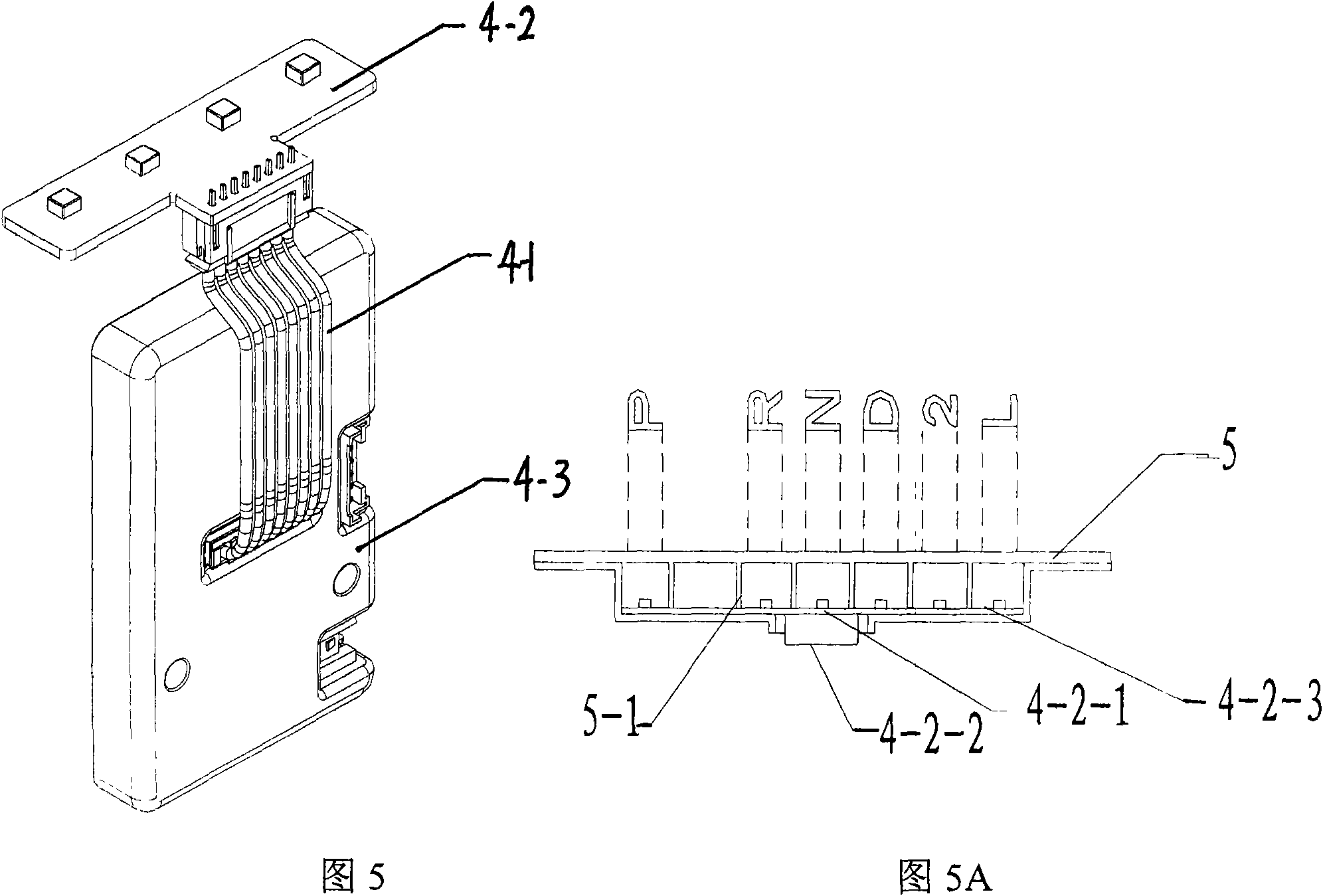

[0062] see figure 1 with figure 2 , the shifter mainly includes a support body assembly 1, a shift arm assembly 2, a solenoid valve assembly 3, an electronic control unit 4, a gear panel 5, a handle assembly 6, a combination of a swing arm and a rotating shaft 7, and manual unlocking Device and unlocking spring 8, upper support 9 and sliding pad assembly 10, etc., their specific structure and assembly relationship are as follows:

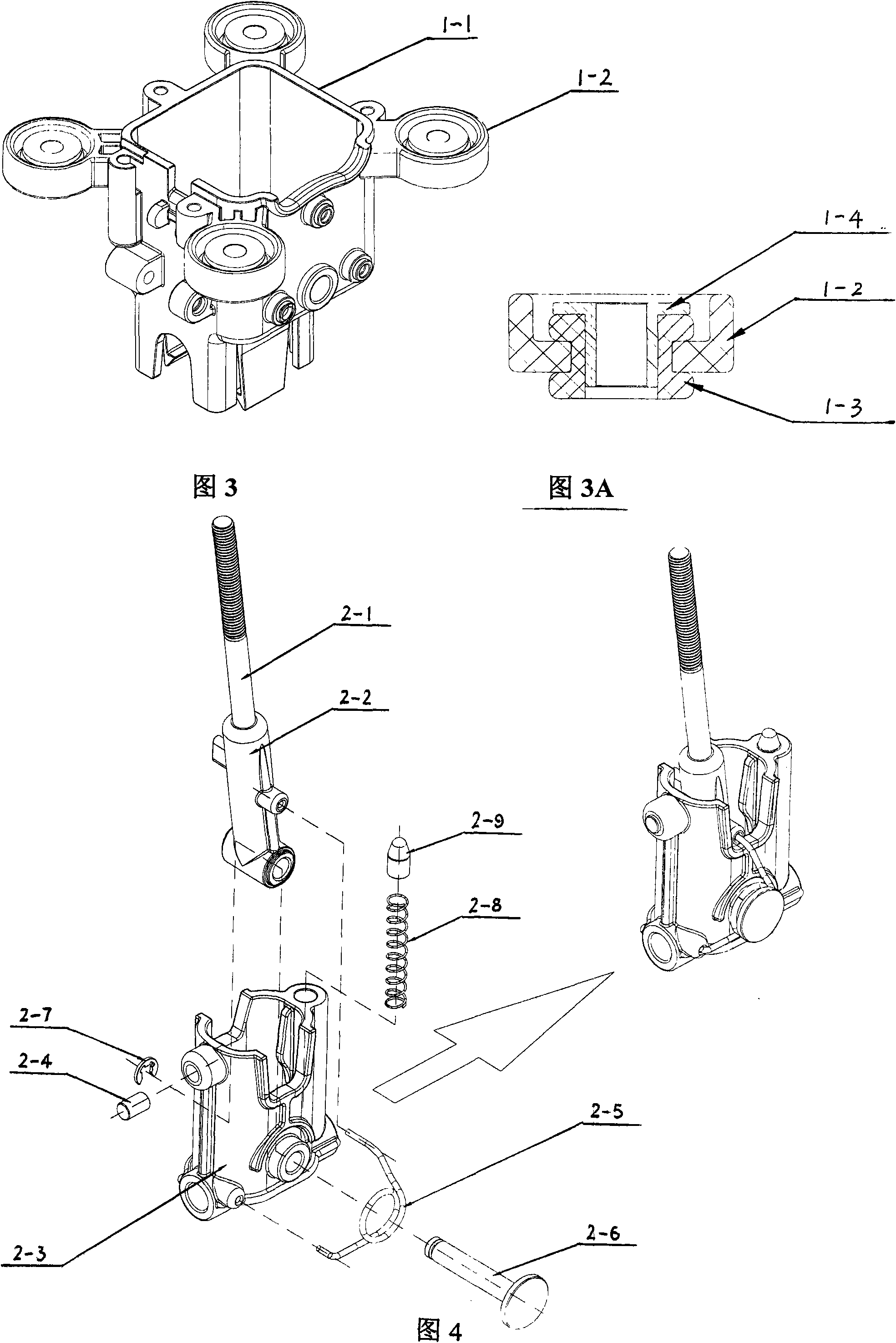

[0063] (1) Support body assembly 1, see image 3 with Figure 3A :

[0064] The assembly includes a support body 1-1 with an inner cavity, four bolt holes 1-2 fixed to the vehicle body are arranged on the outside of the support body 1-1, and a buffer pad 1-3 and The positioning sleeve 1-4 and the buffer pad 1-4 are installed in the bolt hole 1-2 by means of structural limitation, and the connection mode between the positioning sleeve 1-4 and the buffer pad 1-3 adopts interference tension.

[0065] (2) Shift arm assembly 2, see Figure 4 :

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com