Electroforming method and electroforming apparatus commonly acted by ultrasonic wave and laser

A joint action, ultrasonic technology, applied in electroforming, electrolysis process, etc., can solve the problems of uneven thickness, poor material properties, slow electroforming speed, etc., and achieve the effect of improving electroforming speed, good compactness, and speed up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

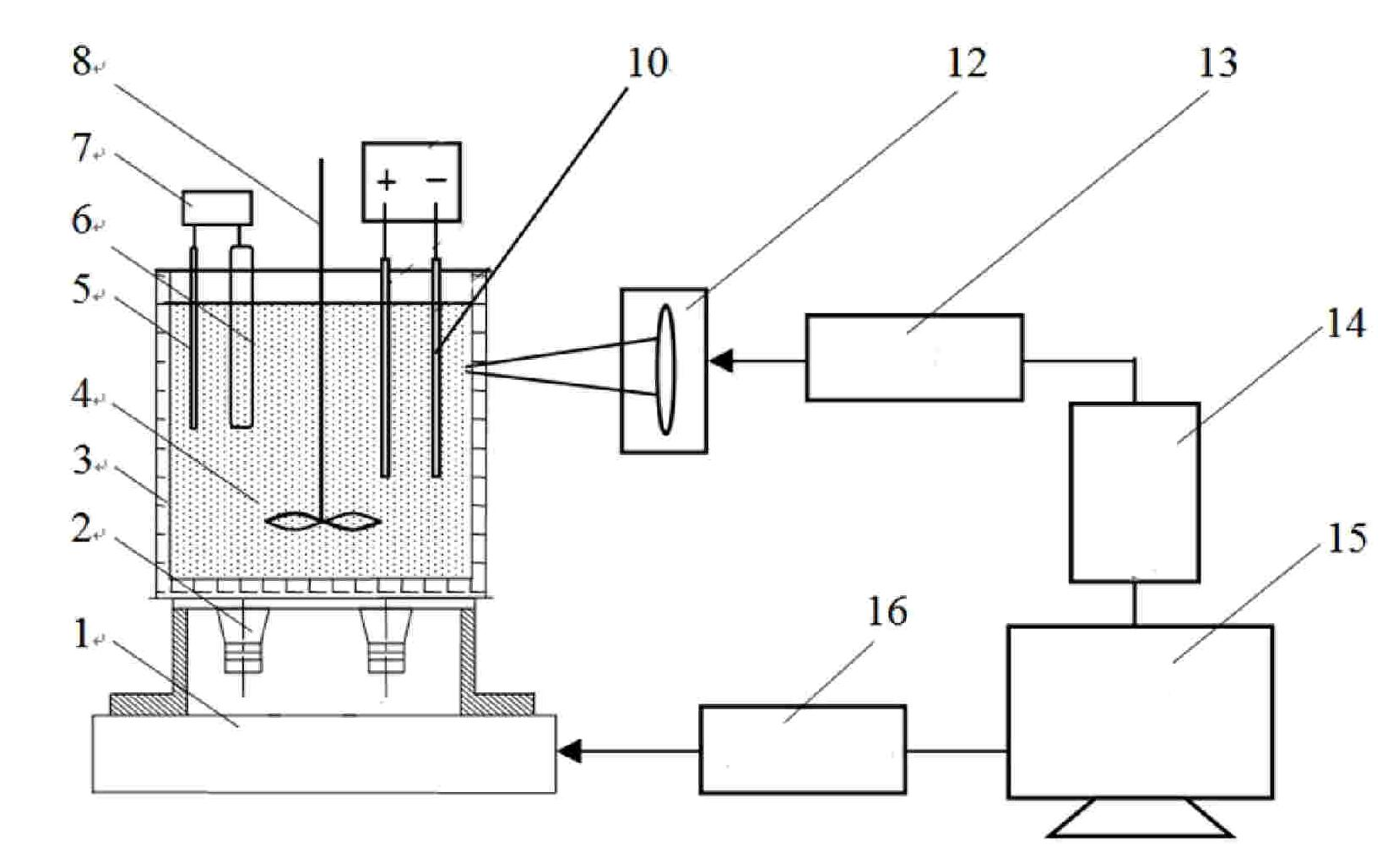

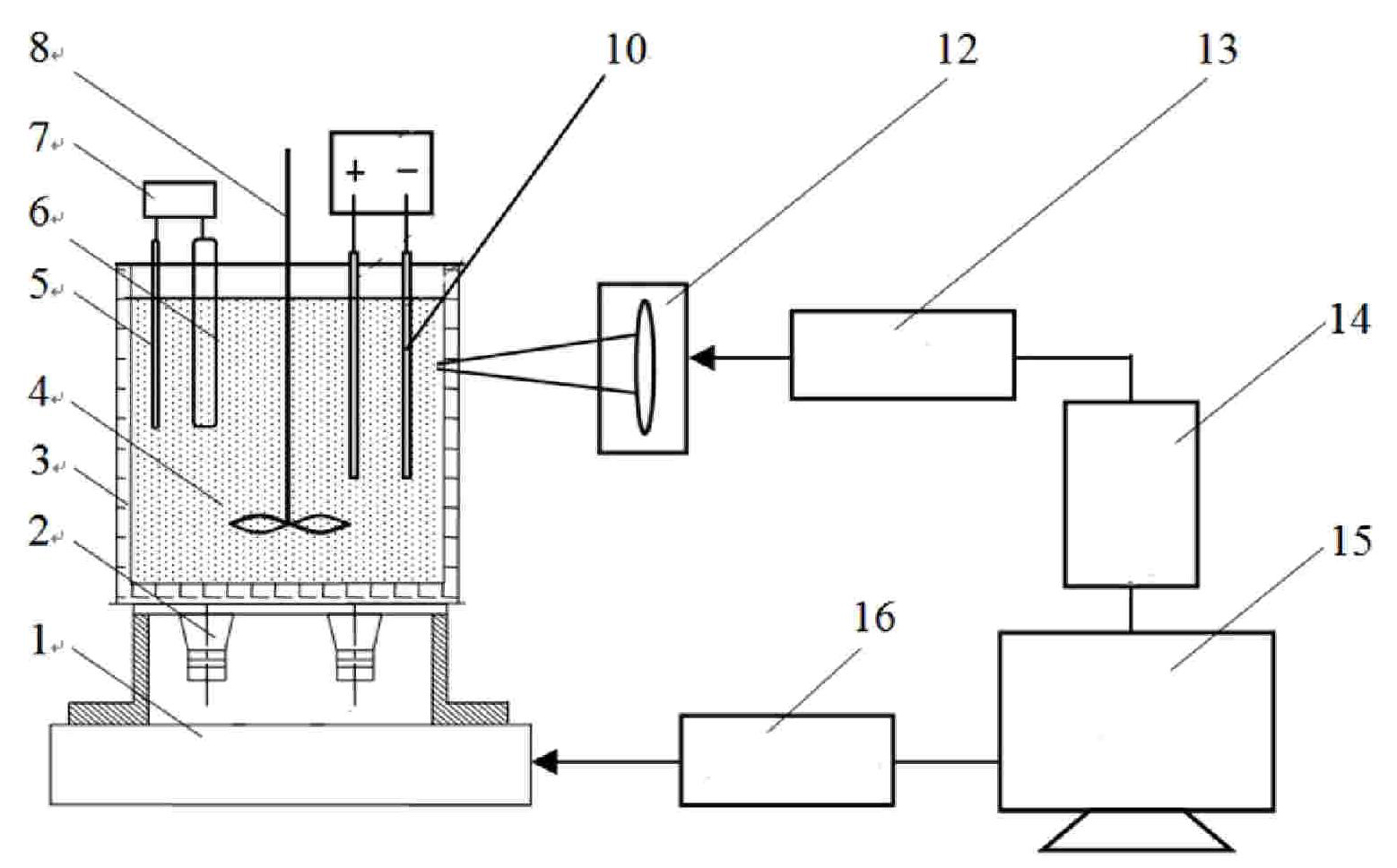

[0021] The electroforming method utilizing ultrasonic wave and laser combined action of the present invention is: during electroforming, ultrasonic wave and laser wave are applied simultaneously in the same electroforming liquid area close to the original mold, ultrasonic wave propagates upward along the vertical direction, and laser wave propagates along the horizontal direction . Ultrasonic waves and laser waves are superimposed in the electroforming liquid adjacent to the original mold to achieve a synergistic effect on the electroforming liquid on the surface of the casting. The power of the ultrasonic generating device adopted in the present embodiment is 950 watts, and the vibration frequency of the ultrasonic wave is greater than 20KHz; the laser generator used is a Nd:YAG continuous laser generator, the rated output power is 50W, and the laser wavelength is 1064nm.

[0022] When electroforming, use DC or pulse power supply to energize, while the original mold moves, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com