Synchronous control system of injection head and wound roll of continuous oil pipe operating machine and control method thereof

A technology of synchronous control and injection head, which is applied to the automatic control system of drilling, drill pipe, casing, etc., which can solve the problems of high manufacturing cost and complex structure, and achieve the effects of low cost, reliable operation, and convenient installation, maintenance and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

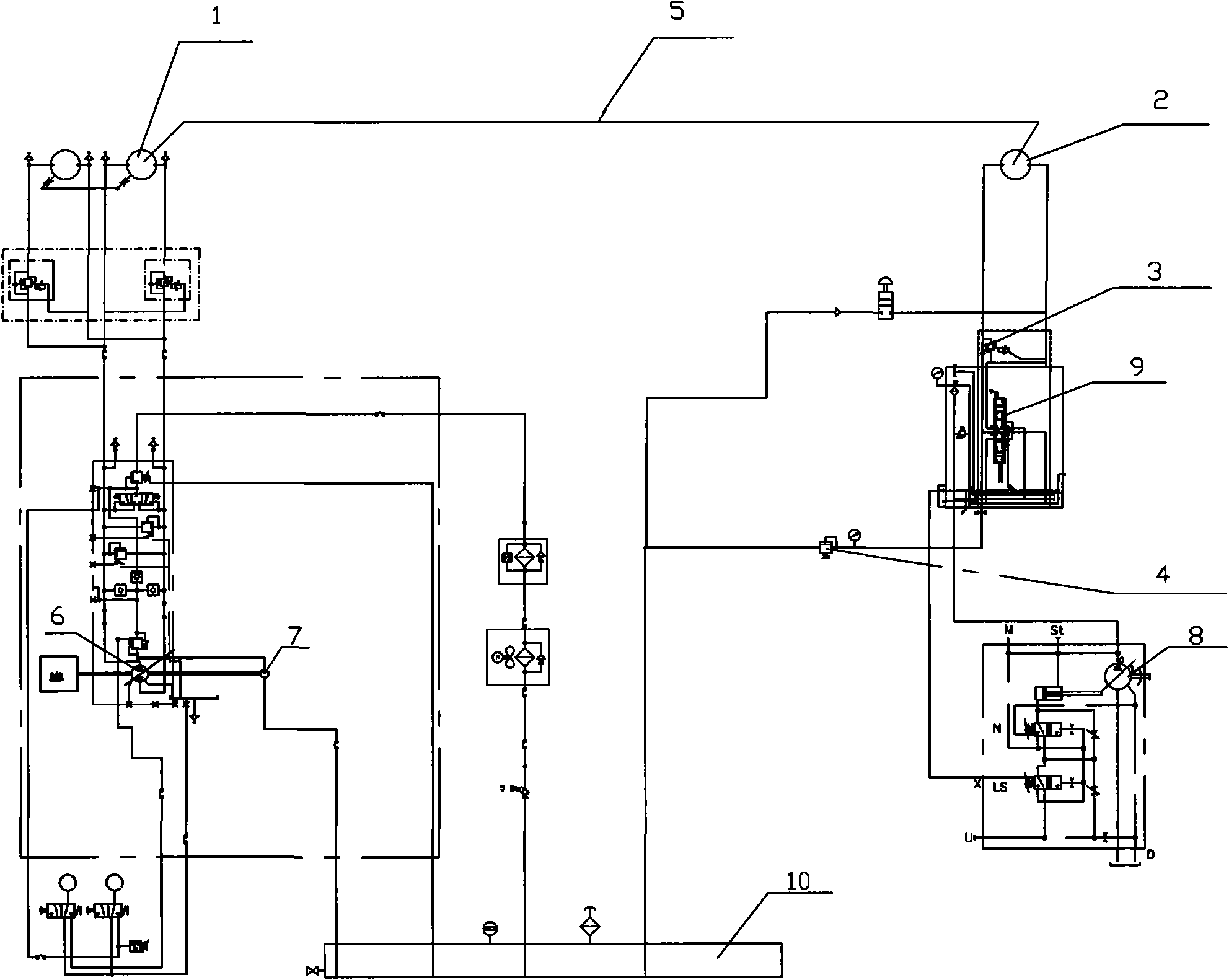

[0017] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a synchronous control system of injection head and reel of coiled tubing machine mainly includes injection head closed transmission subsystem and reel open subsystem, and the injection head closed hydraulic transmission subsystem includes two-way variable A plunger pump 6, a coaxially rotating gear pump 7 and an injection head motor 1, the reel opening subsystem includes a load-sensitive variable pump 8, a manual proportional valve 9 and a reel motor 2, and also includes a variable back pressure valve 3 and overflow valve 4; the variable back pressure valve 3 is installed on the oil return road of the reel motor 2, its oil inlet is connected with the outlet of the reel motor 2, and its oil outlet is connected to the oil tank 10 through the reversing valve connected; the overflow valve 4 is installed on the oil inlet of the reel motor 2, its oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com